Advanced Injection Molding Techniques for Complex Projects

By:Admin

The company, which was founded in [year], has quickly gained a reputation for its commitment to quality and its ability to consistently deliver exceptional results. Specializing in high-precision, tight-tolerance injection molding, Complex Injection Molding has become a trusted partner for a wide range of industries, including automotive, medical, consumer products, and electronics.

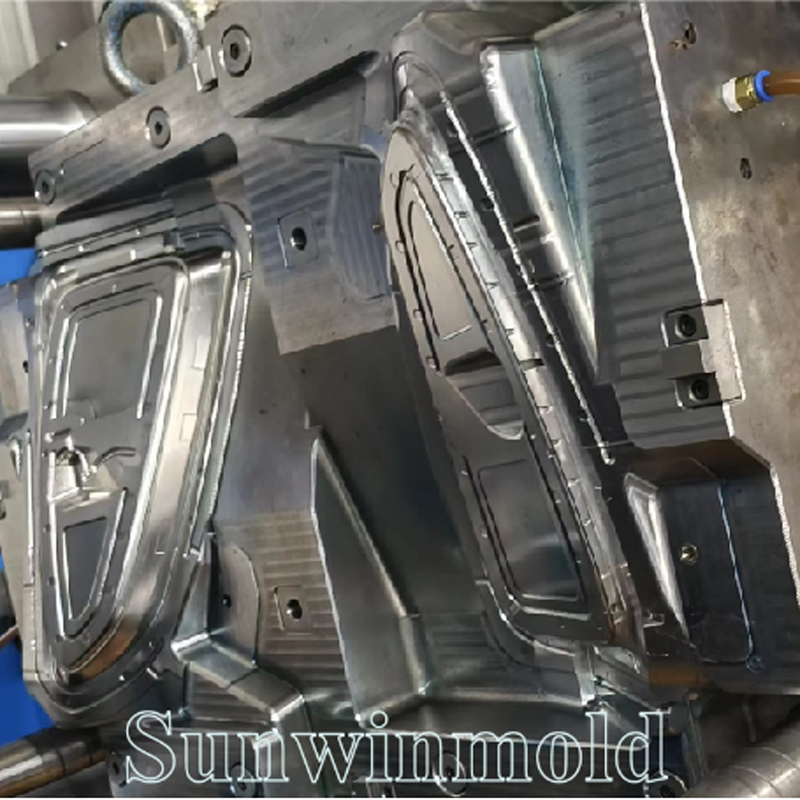

One of the key factors that sets Complex Injection Molding apart from its competitors is its dedication to investing in the latest technology and equipment. The company’s state-of-the-art manufacturing facilities feature an extensive range of injection molding machines, ranging from 20 to 500 tons, which are capable of handling a wide variety of project sizes and complexities. This advanced technology allows Complex Injection Molding to deliver precision-molded parts with unmatched accuracy and consistency, while also maximizing efficiency and reducing production lead times.

In addition to its cutting-edge equipment, Complex Injection Molding also prides itself on its team of experienced engineers and technicians, who are experts in the latest injection molding techniques and best practices. From design and prototyping to production and quality control, the company’s team works closely with clients to ensure that every project meets the highest standards of quality and performance. This commitment to excellence has earned Complex Injection Molding a reputation as a reliable and responsive partner, capable of delivering outstanding results on time and within budget.

Complex Injection Molding’s new line of injection molding solutions represents the company’s ongoing commitment to innovation and continuous improvement. These new solutions are specifically designed to address the evolving needs of the industry, including the increasing demand for complex geometries, tight tolerances, and high-performance materials. By leveraging advanced materials and process control technologies, Complex Injection Molding is able to produce parts with exceptional precision and consistency, while also minimizing waste and maximizing cost-effectiveness.

One of the most exciting aspects of Complex Injection Molding’s new line of solutions is its ability to handle complex and intricate designs with ease. The company’s advanced tooling and process capabilities enable it to produce parts with intricate geometries, thin walls, and challenging features, all while maintaining exceptional dimensional stability and mechanical properties. This level of precision and complexity opens up new possibilities for manufacturers, allowing them to push the boundaries of design and performance in their products.

Another key advantage of Complex Injection Molding’s new solutions is their ability to work with a wide range of high-performance materials, including engineering-grade thermoplastics, elastomers, and advanced composites. This diversity of materials allows the company to meet the unique requirements of different industries and applications, providing clients with the flexibility and versatility they need to bring their innovative ideas to life.

In summary, Complex Injection Molding’s new line of injection molding solutions represents a significant step forward for the company and the industry as a whole. With its advanced technology, skilled team, and commitment to innovation, Complex Injection Molding is well-positioned to meet the evolving needs of manufacturers and deliver exceptional results for years to come.

Company News & Blog

High-Quality Nylon Pellets for Injection Molding: Everything You Need to Know

Nylon Pellets For Injection Molding, a leading manufacturer and supplier of high-quality nylon pellets for various industries, has recently announced their latest range of products designed to meet the growing demand for durable and high-performance materials in the injection molding industry.With an extensive range of nylon pellets in different grades and specifications, Nylon Pellets For Injection Molding has established itself as a reliable and trusted supplier for companies looking for top-notch materials for their production needs. The company has been in the business for over a decade, and their commitment to quality and customer satisfaction has made them a preferred choice for many manufacturers and businesses.Nylon Pellets For Injection Molding offers a wide range of nylon materials, including nylon 6, nylon 66, and specialty blends tailored to specific requirements. These materials are known for their exceptional strength, impact resistance, and heat stability, making them ideal for a wide range of applications, including automotive parts, electrical components, consumer goods, and industrial equipment.One of the key advantages of Nylon Pellets For Injection Molding's products is their versatility and compatibility with different injection molding processes. Whether it's conventional injection molding, insert molding, or overmolding, their nylon pellets are designed to deliver consistent and reliable performance, ensuring smooth and efficient production processes for their clients.In addition to their standard product offerings, Nylon Pellets For Injection Molding also provides custom formulation services, allowing businesses to create tailored nylon materials that meet their exact specifications and performance requirements. This flexibility is part of the company's commitment to providing comprehensive solutions that address the unique needs of their clients in the ever-evolving manufacturing landscape.Furthermore, Nylon Pellets For Injection Molding takes pride in its commitment to sustainability and environmental responsibility. The company works closely with its suppliers to source raw materials from sustainable and ethically responsible sources, ensuring that their products meet the highest standards of environmental stewardship. As the industry continues to prioritize sustainable practices, Nylon Pellets For Injection Molding is well-positioned to support businesses looking to align with these values.As part of their ongoing efforts to innovate and enhance their product offerings, Nylon Pellets For Injection Molding invests in research and development to stay ahead of the curve and anticipate the changing needs of the market. By continuously improving their materials and processes, the company aims to be a reliable partner for businesses seeking cutting-edge solutions for their injection molding needs.With a customer-centric approach, Nylon Pellets For Injection Molding is dedicated to providing exceptional service and support to its clients, offering technical expertise, responsive communication, and reliable delivery to ensure a seamless experience from start to finish. Their team of experienced professionals is always ready to assist customers in finding the right materials and addressing any challenges they may encounter during the manufacturing process.In conclusion, Nylon Pellets For Injection Molding's latest product range underscores the company's dedication to excellence and innovation in providing top-quality nylon materials for the injection molding industry. With a focus on quality, sustainability, and customer satisfaction, the company continues to be a leading force in the market, serving as a trusted partner for businesses looking to elevate their production capabilities with high-performance nylon pellets.

Benefits of Medical Injection Molding for Healthcare Industry

Medical Injection Molding, a leading provider of high-quality injection-molded plastic components for the medical industry, has announced its continued commitment to delivering innovative and cutting-edge solutions to its clients. With a strong focus on precision, quality, and reliability, Medical Injection Molding has established itself as a trusted partner for medical device manufacturers seeking to bring their products to market.With state-of-the-art facilities and a team of experienced engineers and technicians, Medical Injection Molding is equipped to handle the most complex and demanding projects. The company's capabilities include design and engineering support, material selection, prototyping, and high-volume production. Whether it's a small, intricate component or a large, complex part, Medical Injection Molding has the expertise and technology to deliver exceptional results.One of the key strengths of Medical Injection Molding is its ability to work closely with clients throughout the entire development and production process. From the initial concept to the final product, the company's team collaborates with clients to ensure that their needs and specifications are met. This level of partnership and communication sets Medical Injection Molding apart from its competitors, as it allows for a seamless and efficient manufacturing process.In addition to its technical capabilities, Medical Injection Molding places a strong emphasis on quality and compliance. The company is ISO 13485-certified, ensuring that its manufacturing processes adhere to the highest standards for medical device production. This level of certification reflects Medical Injection Molding's commitment to delivering safe and reliable products to its clients and end-users.Furthermore, the company has invested in cutting-edge technology and equipment to enhance its capabilities and improve efficiency. This includes the latest in injection molding machines, automated assembly systems, and quality control equipment. By staying at the forefront of technological advancements, Medical Injection Molding is able to offer its clients the most advanced and cost-effective solutions for their manufacturing needs.With a focus on continuous improvement, Medical Injection Molding is constantly exploring new materials, processes, and technologies to stay ahead of industry trends and meet the evolving needs of its clients. The company's dedication to research and development ensures that it remains a leader in the medical injection molding sector and can provide innovative solutions for even the most challenging projects."Our commitment to delivering exceptional results for our clients is unwavering," says [company representative]. "We understand the critical nature of the medical device industry and the need for precision and reliability. That's why we continually invest in our people, technology, and processes to ensure that we can meet and exceed the expectations of our clients."As the demand for high-quality medical devices continues to grow, Medical Injection Molding is poised to play a crucial role in supporting the industry's needs. With its focus on quality, innovation, and customer satisfaction, the company is well-positioned to continue its success and be a valued partner to medical device manufacturers worldwide.

How to Find the Best Plastic Bucket Mold

Plastic Bucket Mold: Enhancing Sustainable ManufacturingIn the world of manufacturing, sustainability has become an increasingly important consideration. With growing concerns about environmental impact and the need for more eco-friendly processes, companies are seeking innovative solutions to minimize their carbon footprint. One such solution is the development of plastic bucket molds that not only optimize production efficiency but also promote sustainability. One company that has been at the forefront of this movement is ***. With a solid reputation in the manufacturing industry, *** has been dedicated to producing high-quality plastic bucket molds that are not only durable and efficient but also environmentally friendly. By incorporating innovative design and cutting-edge technology, *** has revolutionized the production of plastic buckets, paving the way for a more sustainable approach to manufacturing.The plastic bucket molds developed by *** are designed to meet the diverse needs of the industry. Whether for industrial, commercial, or domestic use, these molds are engineered to produce buckets that are durable, reliable, and cost-effective. By using advanced materials and precision engineering, *** has been able to create molds that ensure the highest level of quality and consistency in each bucket produced. This not only reduces waste but also contributes to a more sustainable manufacturing process.Furthermore, *** has also prioritized environmentally friendly practices in their production process. By implementing energy-efficient technologies and recycling initiatives, *** has significantly reduced its environmental impact. The company has also made a conscious effort to minimize the use of harmful chemicals and utilize sustainable materials in the production of their molds. This commitment to sustainability has earned *** recognition as a leader in eco-friendly manufacturing practices.In addition to their dedication to sustainability, *** has also excelled in providing exceptional customer service. With a team of highly skilled professionals, the company offers comprehensive support to its clients, from initial design and development to production and maintenance. By understanding the unique needs of each client, *** ensures that the plastic bucket molds they provide are customized to meet specific requirements. This personalized approach has helped *** build long-term relationships with clients and establish itself as a trusted partner in the industry.As part of their continuous improvement efforts, *** has also invested in research and development to stay ahead of the curve in the manufacturing industry. By staying abreast of the latest technological advancements and market trends, the company continuously enhances its products to meet the evolving needs of its clients. This dedication to innovation has allowed *** to consistently deliver cutting-edge plastic bucket molds that set new standards in the industry.Looking ahead, *** remains committed to pushing the boundaries of sustainable manufacturing. The company continues to explore new technologies and design methodologies that further reduce environmental impact and enhance production efficiency. With a focus on sustainability, innovation, and customer satisfaction, *** is poised to remain a driving force in the manufacturing of plastic bucket molds.In conclusion, the development of plastic bucket molds by *** has not only revolutionized the manufacturing process but has also set a new standard for sustainability in the industry. By combining advanced technology, eco-friendly practices, and exceptional customer service, *** has established itself as a leading provider of high-quality, sustainable plastic bucket molds. With a continued commitment to innovation and sustainability, *** is driving positive change in the manufacturing industry and setting an example for others to follow.

High-quality 4 Cavity Blow Moulding Machine for Efficient Production

4 Cavity Blow Moulding Machine Revolutionizes Plastic Packaging ProductionIn a significant development for the plastic packaging industry, the latest 4 cavity blow moulding machine has been introduced by {} to revolutionize the production process. With its cutting-edge technology and innovative design, this machine is set to redefine the way plastic packaging is manufactured, offering enhanced efficiency, productivity, and cost-effectiveness.With the increasing demand for plastic packaging across various industries, there has been a growing need for advanced machinery that can meet the evolving requirements of production. The introduction of the 4 cavity blow moulding machine addresses this need by providing a highly efficient and versatile solution for the manufacturing of plastic bottles, containers, and other packaging products.One of the key features of this machine is its capability to produce four bottles simultaneously, thereby increasing the production output and reducing the manufacturing time. This not only enhances the overall productivity of the production process but also leads to significant cost savings for the manufacturers. Additionally, the machine is equipped with cutting-edge technology that ensures the production of high-quality, uniform, and defect-free products, meeting the stringent standards of the industry.Furthermore, the 4 cavity blow moulding machine incorporates advanced automation and control systems, allowing for precise monitoring and adjustment of the production process. This ensures consistent product quality and minimizes the risk of errors or defects during the manufacturing process. The machine also offers a high degree of flexibility, allowing for quick and easy mold changes to accommodate different product specifications and designs.The introduction of this advanced machinery by {} reflects the company's commitment to innovation and excellence in the plastic packaging industry. With years of experience and expertise in the field, {} has established itself as a leading manufacturer and supplier of blow moulding machines and other plastic processing equipment. The introduction of the 4 cavity blow moulding machine is a testament to the company's dedication to providing cutting-edge solutions that meet the evolving needs of the industry."We are thrilled to introduce the latest 4 cavity blow moulding machine, which represents a significant leap forward in plastic packaging production," said a spokesperson for {}. "This machine is the result of our relentless pursuit of innovation and our commitment to meeting the demands of the industry. We believe that this machine will not only enhance the production capabilities of our customers but also contribute to the overall advancement of the plastic packaging sector."The introduction of the 4 cavity blow moulding machine is poised to have a transformative impact on the plastic packaging industry, offering manufacturers a competitive edge through enhanced efficiency, productivity, and quality. As the demand for plastic packaging continues to grow, advanced machinery such as this will play a crucial role in meeting the industry's evolving needs and driving its future growth and development.With its advanced technology, innovative design, and commitment to excellence, the 4 cavity blow moulding machine by {} is set to shape the future of plastic packaging production, offering manufacturers a powerful tool to meet the demands of the market and stay ahead in the competitive landscape.

Mould for Lid Handles: What You Need to Know

Lid Handles Mould: Innovating Mould Design in the Manufacturing IndustryThe manufacturing industry has seen a significant evolution in recent years, with the incorporation of advanced technologies and innovative designs to enhance production processes. One such innovation is the development of lid handles mould, which has revolutionized the production of lid handles for various containers and appliances. This game-changing mould design has been championed by the industry-leading company, whose dedication to innovation and excellence has propelled them to the forefront of the manufacturing industry.With a strong focus on research and development, {company name} has emerged as a pioneer in the manufacturing of moulds for a wide range of products, including lid handles. The company's commitment to pushing the boundaries of traditional mould design has led to the development of cutting-edge technologies that are revolutionizing the industry. The lid handles mould, in particular, has garnered widespread attention for its functionality and efficiency in producing high-quality lid handles for containers and appliances.The lid handles mould designed by {company name} is equipped with advanced features that optimize the production process, resulting in superior quality and consistency in the finished products. This innovative mould design has been meticulously engineered to ensure precision and reliability, meeting the stringent requirements of the manufacturing industry. By leveraging state-of-the-art technology and expertise, {company name} has set a new standard for lid handle production, streamlining the manufacturing process and delivering exceptional results.One of the key advantages of the lid handles mould is its versatility, allowing for the production of a wide variety of lid handles to cater to diverse market demands. Whether it's for food containers, household appliances, or industrial equipment, the mould is capable of producing customized lid handles with varying shapes, sizes, and specifications. This versatility has empowered manufacturers to expand their product offerings and meet the evolving needs of consumers, driving innovation and competitiveness in the market.In addition to its versatility, the lid handles mould is also designed for efficiency, optimizing production processes and minimizing waste. With a focus on sustainability and cost-effectiveness, {company name} has integrated innovative features into the mould design to enhance productivity and reduce material consumption. This commitment to sustainable manufacturing practices underscores the company's dedication to environmental stewardship and responsible production methods.Furthermore, the lid handles mould exemplifies {company name}'s unwavering commitment to quality and excellence. Rigorous quality control measures are implemented throughout the manufacturing process, ensuring that every lid handle produced meets the highest standards of durability, functionality, and aesthetics. By upholding these stringent quality standards, {company name} has earned a reputation for delivering exceptional products that exceed customer expectations and industry benchmarks.As a testament to its leadership in mould design and manufacturing, {company name} continues to collaborate with industry partners and clients to drive innovation and address evolving market demands. The company's relentless pursuit of excellence and customer satisfaction has cemented its position as a trusted partner for businesses seeking high-quality mould solutions. Whether it's for lid handles or other custom moulding needs, {company name} stands ready to deliver cutting-edge solutions that elevate production capabilities and drive business growth.In conclusion, the lid handles mould developed by {company name} represents a paradigm shift in the manufacturing industry, showcasing the company's dedication to innovation, quality, and sustainability. As the industry continues to embrace advanced technologies and forward-thinking solutions, {company name} remains at the forefront, leading the way with its innovative mould designs and commitment to excellence. With a steadfast focus on driving progress and exceeding industry standards, {company name} is poised to shape the future of manufacturing with its groundbreaking solutions and unwavering dedication to customer success.

High Speed Injection Mould for Thin Wall Products: A Brief Overview

, the following is a sample article.---Introducing the Next Generation Thin Wall High-Speed Injection MouldInnovation has always been at the forefront of {Company Name}'s philosophy, and now they are proud to introduce their latest breakthrough - the Thin Wall High-Speed Injection Mould. This cutting-edge technology promises to revolutionize the injection moulding industry by allowing for faster production speeds and increased efficiency.The Thin Wall High-Speed Injection Mould has been designed to meet the growing demand for lightweight and durable plastic products. With the ability to produce ultra-thin wall thicknesses, this innovative technology is set to open up new possibilities for a wide range of industries, from automotive and electronics to packaging and consumer goods.One of the key features of the Thin Wall High-Speed Injection Mould is its advanced cooling system, which enables faster cycle times and reduces overall production costs. This is achieved through the use of high-conductivity materials and innovative cooling channel designs, which maximize heat transfer and minimize cooling time.Furthermore, the mould is equipped with a state-of-the-art servo motor system, which ensures precise and consistent injection speeds, resulting in higher-quality products with minimal waste. This level of control and accuracy is unprecedented in the industry, and is set to raise the bar for injection moulding standards.In addition to its technical capabilities, the Thin Wall High-Speed Injection Mould is also designed with user-friendly features that make it easy to operate and maintain. Its modular design allows for quick and easy tool changes, while its intuitive control interface provides operators with real-time monitoring and diagnostics.{Company Name} has a long-standing reputation for delivering reliable and high-quality injection moulding solutions, and the introduction of the Thin Wall High-Speed Injection Mould is a testament to their commitment to innovation and excellence. With a team of experienced engineers and industry experts, {Company Name} is dedicated to providing customers with cutting-edge technology that meets their specific needs and requirements.The Thin Wall High-Speed Injection Mould is a testament to {Company Name}'s dedication to innovation and excellence, and is set to redefine the standards for high-speed injection moulding. With its advanced cooling system, precise servo motor control, and user-friendly features, this revolutionary technology promises to deliver faster production speeds, increased efficiency, and higher-quality products. As the demand for lightweight and durable plastic products continues to grow, the Thin Wall High-Speed Injection Mould is set to play a key role in shaping the future of the injection moulding industry. With its unparalleled performance and innovative design, it is clear that {Company Name} is once again at the forefront of technological advancement, and is leading the way towards a new era of injection moulding excellence.In conclusion, the introduction of the Thin Wall High-Speed Injection Mould marks a significant milestone for {Company Name} and the injection moulding industry as a whole. With its groundbreaking technology and user-friendly design, this innovative solution is poised to revolutionize production processes and empower businesses to meet the growing demands of their customers. As {Company Name} continues to push the boundaries of what is possible, it is clear that the future of injection moulding is in good hands.

Mold Injection Molding for Family Products

Family Mold Injection Molding, a prominent player in the injection molding industry, is making waves with its innovative and cost-effective manufacturing solutions. The company, headquartered in [location], has established a strong track record of providing high-quality injection molding services to a wide range of industries, including automotive, medical, consumer goods, and electronics.With over [number] years of experience in the industry, Family Mold has distinguished itself through its commitment to excellence, customer-centric approach, and advanced manufacturing capabilities. The company's state-of-the-art facility is equipped with the latest injection molding machines and technology, allowing it to deliver precision-engineered plastic components that meet the highest standards of quality and performance.Family Mold prides itself on its ability to provide end-to-end manufacturing solutions, from design and prototyping to full-scale production. Its team of skilled engineers and technicians work closely with clients to develop custom molding solutions that are tailored to their specific needs and requirements. This collaborative approach ensures that every project is executed with precision and efficiency, resulting in cost-effective and timely delivery of high-quality plastic parts.One of the key differentiators of Family Mold is its expertise in multi-cavity molding, which allows for the simultaneous production of multiple parts in a single cycle. This capability not only increases production efficiency but also reduces manufacturing costs, making it an attractive option for clients looking to streamline their production processes.In addition, Family Mold offers a range of post-molding services such as assembly, packaging, and quality control, further adding value to its clients by providing a complete manufacturing solution under one roof. This comprehensive approach simplifies the supply chain and ensures that all components meet the strictest quality standards before they are delivered to the customer.Furthermore, the company is dedicated to sustainable manufacturing practices and has implemented various initiatives to reduce energy consumption, waste generation, and environmental impact. Family Mold recognizes the importance of corporate responsibility and is committed to playing its part in promoting a greener and more sustainable future for the industry.Moreover, Family Mold is actively investing in research and development to stay at the forefront of technological advancements in injection molding. By continually upgrading its machinery and processes, the company ensures that it can meet the evolving needs of its clients and deliver cutting-edge solutions that set new benchmarks in the industry.With a strong focus on customer satisfaction, Family Mold prides itself on its ability to consistently deliver on its promises and exceed expectations. Whether it's a small-scale prototype or a large-scale production run, the company approaches each project with the same level of dedication and attention to detail, earning it a reputation as a trusted and reliable manufacturing partner.As a testament to its commitment to quality and excellence, Family Mold has earned several certifications and accolades, including ISO [number] and [other certifications], further solidifying its position as a leader in the injection molding industry.In conclusion, Family Mold Injection Molding continues to raise the bar in the industry by offering innovative and cost-effective manufacturing solutions that meet the diverse needs of its clients. With its advanced capabilities, commitment to quality, and customer-centric approach, the company is well-positioned to drive the future of injection molding and deliver superior results for years to come.

Leading Chinese Car Exterior Door Trim Factory Offers Quality Products

China's Leading Car Exterior Door Trim Factory Revolutionizes Automotive IndustryIn a major stride towards innovation in the automotive industry, China's prominent car exterior door trim factory has introduced cutting-edge technology and manufacturing processes. With a steadfast commitment to quality, precision, and customer satisfaction, this leading factory aims to reshape the car door trim market domestically and internationally.Established with a vision to cater to the burgeoning automotive market in China and beyond, the factory has rapidly gained recognition as a trusted manufacturer of car exterior door trim. By integrating advanced machinery, specialized tools, and high-quality materials, the factory ensures the production of superior door trim products that enhance both the aesthetics and functionality of vehicles.One of the key factors contributing to the factory's success is their relentless pursuit of innovation. By consistently investing in research and development, they have stayed abreast of the latest industry trends and technological advancements. This approach has enabled them to develop and manufacture door trim products that surpass customer expectations in terms of durability, design, and functionality.Moreover, the factory's commitment to quality control is unwavering. Every stage of production undergoes strict scrutiny, from material selection to the final inspection. This meticulous attention to detail ensures that each car exterior door trim leaving the factory is of the highest standards, meeting or exceeding global quality benchmarks.The factory boasts state-of-the-art facilities that utilize the most advanced manufacturing techniques. Equipped with cutting-edge robotics, computer numerical control (CNC) machines, and automated systems, the factory maximizes efficiency and accuracy in the production process. These technologies allow for precise customization of door trim components, catering to the diverse needs and specifications of various car models.Furthermore, the factory places great importance on environmental sustainability. Recognizing the global shift towards eco-friendly practices, they have implemented energy-efficient processes and eliminated harmful emissions. By adhering to stringent environmental regulations, they ensure that their manufacturing practices align with worldwide sustainability standards.To maintain their leading position in the market, the factory prioritizes continuous improvement. They actively engage with industry experts, collaborate with renowned design firms, and invest in training programs for their staff. These initiatives nurture innovation, foster creativity, and enhance the factory's overall competitiveness in the automotive industry.As a result of their unwavering dedication to cutting-edge technology, quality control, efficiency, and sustainability, the factory has earned the trust of numerous domestic and international automobile manufacturers. Their car exterior door trim products have become the go-to choice for industry giants, catering to a wide range of vehicle models that vary in size, style, and function.Looking towards the future, the factory intends to further diversify its product range. By expanding their manufacturing capabilities and incorporating advanced materials, they aim to introduce revolutionary door trim solutions. Anticipating the rise of electric vehicles, they are also investing in research and development to create innovative door trim designs that align with the unique requirements of this growing sector.With their commitment to excellence, reliability, and customer satisfaction, China's leading car exterior door trim factory is poised to transform the automotive industry. Their continuous pursuit of innovation and dedication to quality ensure that both domestic and international customers will experience the epitome of product perfection when choosing their car exterior door trim.

Ultimate Guide to Scientific Injection Molding for High-Quality Products

Scientific Injection Molding, also known as SIM, is a cutting-edge technology that has revolutionized the injection molding industry. By using advanced scientific principles and state-of-the-art equipment, SIM allows for more precise and efficient production of plastic parts. This technology has been widely adopted by manufacturers across various industries, and it has proven to be a game-changer in the world of plastic manufacturing.One company that has fully embraced the power of Scientific Injection Molding is {}. Founded in {}, {} is a leading provider of plastic injection molding services. The company has always prided itself on staying at the forefront of technological advancements in the industry, and their adoption of SIM has further cemented their position as an innovator in the field.{}The company’s expertise in SIM is unrivaled, thanks to their investment in cutting-edge equipment and their team of highly skilled engineers and technicians. By leveraging the power of Scientific Injection Molding, they are able to offer their clients a wide range of benefits, including:1. Enhanced Precision: SIM allows for tighter control over the molding process, resulting in parts with incredibly precise dimensions and specifications. This level of precision is essential for industries where accuracy is paramount, such as aerospace, automotive, and medical manufacturing.2. Improved Efficiency: By optimizing the molding process, SIM reduces production cycle times and minimizes material waste, leading to significant cost savings for clients. This efficiency also allows {} to meet tight deadlines and deliver high volumes of parts in a timely manner.3. Superior Quality: The advanced scientific principles behind SIM ensure that the molded parts are free from defects and imperfections, leading to higher overall quality and reliability. This is crucial for industries where safety and performance are non-negotiable.4. Design Flexibility: With SIM, {} can produce complex geometries and intricate designs that would be challenging or impossible to achieve with traditional molding methods. This opens up new possibilities for their clients and allows them to bring their innovative ideas to life.{}In addition to these benefits, {} has also focused on sustainability in their SIM processes. They have implemented eco-friendly materials and optimized their manufacturing processes to minimize environmental impact, aligning with the growing demand for sustainable manufacturing practices.{}The company’s commitment to excellence and continuous improvement has made them a trusted partner for businesses seeking high-quality plastic molding solutions. Whether it’s for prototyping, low-volume production, or large-scale manufacturing, {} has the expertise and capabilities to meet their clients’ needs.As the demand for precision, efficiency, and quality in plastic molding continues to rise, Scientific Injection Molding has become an indispensable technology for manufacturers around the world. With their dedication to mastering this cutting-edge approach and their track record of success, {} is well-positioned to lead the way in the exciting future of plastic injection molding. Their commitment to pushing the boundaries of what’s possible in their industry is a testament to their passion for innovation and their unwavering dedication to exceeding their clients' expectations.In conclusion, Scientific Injection Molding has truly transformed the way plastic parts are manufactured, and {} is at the forefront of harnessing its power to deliver exceptional results for their clients. With their expertise, dedication, and state-of-the-art capabilities, {} is poised to continue setting new standards of excellence in the world of injection molding.