Gas Assisted Injection Molding Factories in China

By:Admin

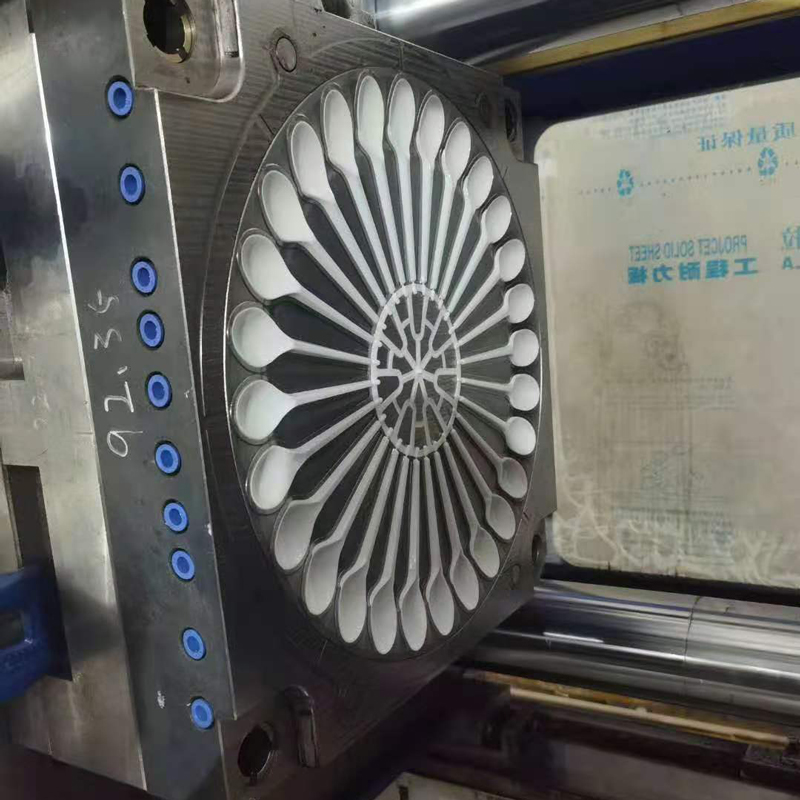

China's gas assisted injection molding industry has experienced significant growth over the past few years, driven by the increasing demand for high-quality plastic products in various sectors. Several leading gas assisted injection molding factories in China have made substantial investments in cutting-edge technology, further solidifying the country's position as a global leader in the manufacturing industry.

One of the prominent companies in this industry, [Brand Name], has recently introduced groundbreaking advancements in gas assisted injection molding technology. With over [number] years of experience in the field, [Brand Name] has established itself as a trusted and reliable partner for clients seeking innovative solutions for their plastic molding needs.

The company's gas assisted injection molding technology offers numerous advantages over traditional plastic molding methods. By using gas to create hollow sections within the plastic parts, the process allows for the production of lightweight yet durable components. This results in cost savings for clients, as less material is required to achieve the desired structural integrity.

Furthermore, the gas assisted injection molding process enhances the surface finish of the plastic parts, reducing the need for secondary finishing processes. This not only streamlines the production process but also ensures a high level of precision and consistency in the final products.

[Brand Name] has also integrated advanced automation systems into its gas assisted injection molding process, further improving efficiency and productivity. By leveraging robotics and intelligent control systems, the company has optimized its manufacturing operations, reducing cycle times and minimizing the risk of errors.

Moreover, [Brand Name] is committed to sustainability and environmental responsibility. The gas assisted injection molding process minimizes material waste, contributing to a more eco-friendly manufacturing approach. Additionally, the company has implemented energy-efficient practices in its production facilities, reducing its carbon footprint and overall environmental impact.

In line with China's focus on innovation and technological advancement, [Brand Name] continues to invest in research and development to further enhance its gas assisted injection molding capabilities. The company's state-of-the-art laboratories and testing facilities allow its team of engineers and experts to conduct comprehensive studies and experiments, leading to the development of new and improved molding techniques.

Furthermore, [Brand Name] places a strong emphasis on collaboration and partnership with its clients. The company works closely with businesses across various industries to understand their specific needs and requirements, tailoring its gas assisted injection molding solutions to meet the unique demands of each project.

As a testament to its commitment to excellence, [Brand Name] has obtained various industry certifications and accreditations, demonstrating its adherence to the highest quality standards and best practices in the manufacturing sector. The company's dedication to continuous improvement and customer satisfaction has earned it a strong reputation within the gas assisted injection molding industry.

Looking ahead, [Brand Name] is poised to capitalize on the growing demand for advanced plastic molding solutions in China and beyond. With its cutting-edge gas assisted injection molding technology, commitment to sustainability, and focus on innovation, the company is well-positioned to remain at the forefront of the industry and drive further advancements in the field.

In summary, the unveiling of the latest advancements in gas assisted injection molding technology by leading factories in China, such as [Brand Name], highlights the country's ongoing progress and leadership in the global manufacturing landscape. As the industry continues to evolve, these developments promise to revolutionize the production of high-quality plastic components and propel China's gas assisted injection molding sector to new heights.

Company News & Blog

China Poultry Packaging Box Mold Manufacturer Offers High-Quality Products

China Poultry Boxes Mould Manufacturer Leads the Way in Innovative Food Packaging SolutionsAs the demand for safe and sustainable food packaging continues to soar around the world, China has emerged as a prominent player in the industry. Among the many manufacturers, one company stands out for its ability to deliver cutting-edge solutions and cater to the unique needs of the global market - China Poultry Boxes Mould Manufacturer (hereafter referred to as CPC).CPC has established itself as a leading figure in the sector, driven by its commitment to innovation, quality craftsmanship, and customer satisfaction. With years of experience in the industry, the company has gained a deep understanding of the evolving demands of the poultry packaging market. By leveraging its expertise, CPC has successfully developed a range of high-quality poultry boxes moulds that have gained recognition both domestically and internationally.One of the key reasons behind CPC's success is its unwavering focus on innovation. The company employs a team of experienced designers and engineers who constantly strive to improve existing mould designs and develop new ones that are tailored to meet the unique requirements of the poultry industry. This dedication to innovation allows CPC to provide its customers with packaging solutions that not only keep their products fresh but also enhance their brand image.In addition to its commitment to innovation, CPC is known for its uncompromising approach to quality craftsmanship. The company utilizes advanced manufacturing techniques and top-of-the-line materials to produce moulds that meet the highest standards of quality. Rigorous quality control measures are followed at every stage of the production process, ensuring that each mould is free from defects and capable of withstanding the demands of the poultry packaging industry.Furthermore, CPC understands the significance of sustainability in today's environmentally conscious world. The company actively works towards reducing its environmental footprint by adopting eco-friendly practices in its manufacturing processes. CPC's moulds are designed to be reusable and highly durable, reducing waste and promoting a circular economy. By investing in sustainable packaging solutions, CPC both meets market demands and contributes to a greener and more sustainable future.CPC's dedication to customer satisfaction is another factor that sets it apart from its competitors. The company understands that each customer has unique requirements and consistently strives to meet these needs. By engaging in close collaboration with its clients, CPC ensures that its moulds are customized to their specifications, guaranteeing a perfect fit for their poultry packaging needs. The company also provides exceptional customer support services, ensuring a smooth and hassle-free experience for its clients.The success of CPC's innovative and high-quality moulds has not gone unnoticed. The products have gained significant recognition in both domestic and international markets, making the company a preferred choice among poultry packaging manufacturers. CPC's moulds have been exported to various countries, which is a testament to the company's commitment to delivering world-class products that meet global standards.Looking ahead, CPC shows no signs of slowing down its quest for innovation and excellence. The company is continuously exploring new technologies and materials to develop even more advanced and sustainable food packaging solutions. By keeping abreast of industry trends and customer demands, CPC aims to remain at the forefront of the poultry packaging market and continue its mission to provide safe, efficient, and eco-friendly packaging solutions.In conclusion, China Poultry Boxes Mould Manufacturer has established itself as a leading player in the global food packaging industry. Through its unwavering commitment to innovation, quality craftsmanship, sustainability, and customer satisfaction, CPC has become the go-to choice for poultry packaging manufacturers worldwide. With a focus on continuous improvement and a dedication to meeting the evolving demands of customers, CPC is set to shape the future of the industry and contribute to a more sustainable and efficient food packaging ecosystem.

Top Medical Injection Molding Companies Facilitating Advanced Healthcare Solutions

Medical Injection Molding Companies Revolutionizing Healthcare Sector In recent years, the rapid advancement of medical injection molding technology has revolutionized the healthcare sector, improving patient care and transforming the way medical devices are manufactured. One notable player in this field is a leading medical injection molding company, which has been at the forefront of innovation and has established itself as a trusted partner in the medical device industry. With its high-quality products, cutting-edge technology, and dedication to meeting customer needs, this company has become a key player in shaping the future of healthcare.Founded over two decades ago, this medical injection molding company has grown from a small operation to a global leader in its field. The company's success lies in its commitment to producing superior medical devices that meet the highest industry standards. By leveraging advanced injection molding techniques, they are able to manufacture intricate and precise components that are crucial for the functioning of medical devices.One of the company's greatest strengths is its state-of-the-art manufacturing facilities. Equipped with the latest technology, including advanced robotics and computer-aided design (CAD) systems, these facilities enable the company to produce a wide range of medical devices with unprecedented precision and efficiency. Additionally, strict quality control measures are in place throughout the manufacturing process to ensure that each product meets the rigorous standards set by regulatory bodies.Another key aspect that sets this company apart is its emphasis on research and development (R&D). The company invests heavily in R&D to stay ahead of industry trends and develop innovative solutions in collaboration with its customers. By working closely with medical professionals and understanding their specific needs, they are able to design and manufacture products that address critical healthcare challenges.In recent years, a growing trend within the medical device industry has been the shift towards miniaturization. This is where the expertise of medical injection molding companies becomes indispensable. Through precise injection molding techniques, these companies are able to produce complex, miniature components that are essential for the development of smaller, portable medical devices. This advancement has allowed for greater patient convenience, increased portability, and improved overall patient experience.The medical injection molding company understands the importance of sustainability and environmental responsibility. It employs various eco-friendly practices throughout its operations, such as the use of bio-based materials and recycling programs. By minimizing waste and reducing its carbon footprint, the company demonstrates its commitment to a greener future.Furthermore, this company prioritizes customer satisfaction and aims to build long-term partnerships. With a team of experienced engineers and designers, they offer comprehensive support to their clients, from product design and development to manufacturing and distribution. By providing customized solutions and maintaining open lines of communication, they ensure that their customers' unique needs are met.In conclusion, medical injection molding companies have played a crucial role in transforming the healthcare sector by providing advanced, high-quality medical devices. This leading medical injection molding company, with its dedication to innovation and commitment to customer satisfaction, has emerged as a key player in the industry. Through its state-of-the-art manufacturing facilities, emphasis on R&D, and focus on sustainability, the company continues to shape the future of healthcare. As technology continues to advance, we can expect further advancements from this company and others in the field, driving the healthcare sector to new heights.

Leading Chinese Car Exterior Door Trim Factory Offers Quality Products

China's Leading Car Exterior Door Trim Factory Revolutionizes Automotive IndustryIn a major stride towards innovation in the automotive industry, China's prominent car exterior door trim factory has introduced cutting-edge technology and manufacturing processes. With a steadfast commitment to quality, precision, and customer satisfaction, this leading factory aims to reshape the car door trim market domestically and internationally.Established with a vision to cater to the burgeoning automotive market in China and beyond, the factory has rapidly gained recognition as a trusted manufacturer of car exterior door trim. By integrating advanced machinery, specialized tools, and high-quality materials, the factory ensures the production of superior door trim products that enhance both the aesthetics and functionality of vehicles.One of the key factors contributing to the factory's success is their relentless pursuit of innovation. By consistently investing in research and development, they have stayed abreast of the latest industry trends and technological advancements. This approach has enabled them to develop and manufacture door trim products that surpass customer expectations in terms of durability, design, and functionality.Moreover, the factory's commitment to quality control is unwavering. Every stage of production undergoes strict scrutiny, from material selection to the final inspection. This meticulous attention to detail ensures that each car exterior door trim leaving the factory is of the highest standards, meeting or exceeding global quality benchmarks.The factory boasts state-of-the-art facilities that utilize the most advanced manufacturing techniques. Equipped with cutting-edge robotics, computer numerical control (CNC) machines, and automated systems, the factory maximizes efficiency and accuracy in the production process. These technologies allow for precise customization of door trim components, catering to the diverse needs and specifications of various car models.Furthermore, the factory places great importance on environmental sustainability. Recognizing the global shift towards eco-friendly practices, they have implemented energy-efficient processes and eliminated harmful emissions. By adhering to stringent environmental regulations, they ensure that their manufacturing practices align with worldwide sustainability standards.To maintain their leading position in the market, the factory prioritizes continuous improvement. They actively engage with industry experts, collaborate with renowned design firms, and invest in training programs for their staff. These initiatives nurture innovation, foster creativity, and enhance the factory's overall competitiveness in the automotive industry.As a result of their unwavering dedication to cutting-edge technology, quality control, efficiency, and sustainability, the factory has earned the trust of numerous domestic and international automobile manufacturers. Their car exterior door trim products have become the go-to choice for industry giants, catering to a wide range of vehicle models that vary in size, style, and function.Looking towards the future, the factory intends to further diversify its product range. By expanding their manufacturing capabilities and incorporating advanced materials, they aim to introduce revolutionary door trim solutions. Anticipating the rise of electric vehicles, they are also investing in research and development to create innovative door trim designs that align with the unique requirements of this growing sector.With their commitment to excellence, reliability, and customer satisfaction, China's leading car exterior door trim factory is poised to transform the automotive industry. Their continuous pursuit of innovation and dedication to quality ensure that both domestic and international customers will experience the epitome of product perfection when choosing their car exterior door trim.

Newly Developed Water Dripper Mold Revolutionizes Drip Irrigation Systems

Title: Innovative Water Dripper Mould Revolutionizes Water Conservation EffortsIntroduction:Water scarcity is a growing concern across the globe, pushing us to seek innovative solutions to conserve this precious resource. One company leading the charge in this domain is a renowned manufacturer that specializes in creating cutting-edge moulds for a wide range of products. Recently, they have developed an advanced Water Dripper Mould that promises to revolutionize water conservation efforts by optimizing efficiency and performance. This groundbreaking invention is set to make a significant impact in the water conservation industry.1. Background:Water conservation is an urgent issue as the world population continues to grow and water scarcity becomes more prevalent. Every drop of water counts, and utilizing it wisely is crucial for the sustenance of life on earth. Acknowledging this, the team at [Company Name] has developed a highly efficient Water Dripper Mould that aims to reduce water wastage and increase water saving capabilities in various industries.2. Functionality and Design:The Water Dripper Mould is designed to provide controlled drip irrigation to various plants, optimizing water usage and reducing overall wastage. This innovative mould ensures that plants receive only the required amount of water, preventing overwatering and allowing for precise irrigation. The design incorporates a fine nozzle and adjustable water flow mechanism, enabling users to customize the volume and intensity of water drips per plant.3. Efficiency and Performance:The Water Dripper Mould's advanced engineering enables it to operate efficiently and reliably in various conditions. It minimizes evaporation, ensuring that a greater percentage of water reaches the plants' root systems instead of being lost to the atmosphere. This promotes healthier plant growth and reduces the overall water needed. Additionally, the mould's precision eliminates the risk of water runoff, preventing soil erosion and nutrient depletion in the surrounding areas.4. Multifunctional Applications:The versatility of the Water Dripper Mould allows it to be utilized in a wide array of industries. It can be integrated seamlessly into agriculture, horticulture, urban gardening, greenhouse farming, and even residential garden settings. The mould's adaptability makes it an ideal choice for both small-scale plantations and large-scale farming operations, serving as a cost-effective solution for sustainable water conservation.5. Environmental Impact:The Water Dripper Mould has the potential to significantly reduce water waste, leading to positive environmental outcomes. By promoting efficient water usage in agriculture and gardening, it aids in the conservation of natural resources and reduces the strain on freshwater ecosystems. As a result, this cutting-edge mould contributes to the overall goal of achieving a greener, more sustainable future.6. Cost-Effectiveness and Longevity:The Water Dripper Mould is designed to be long-lasting and durable, ensuring that it provides optimal performance for an extended period. Its sturdy construction and high-quality materials make it resistant to wear and tear, enabling it to withstand varying weather conditions. Moreover, the water-saving capabilities of this mould ultimately translate into reduced water bills for industries and homeowners, making it an economically viable option.7. Conclusion:With water scarcity becoming an increasingly critical concern worldwide, innovative solutions such as the Water Dripper Mould play a vital role in driving water conservation efforts. [Company Name]'s revolutionary invention demonstrates a commitment to sustainability, providing industries and individuals with a cost-effective, efficient, and environmentally friendly solution for water management. By embracing this innovative mould, we can all contribute towards a more water-efficient future, ensuring the availability of clean water for generations to come.

Discover Precision Injection Molding Techniques for High-Quality Plastic Parts

Title: Advancements in Plastic Molding Propels Manufacturing Industry ForwardIntroduction:The field of plastic molding has witnessed remarkable advancements over the years, resulting in a significant transformation of the manufacturing industry. One prominent player in this sector, referred to as "Prototype Plastic Molding" in this article, has emerged as a pioneer in delivering cutting-edge plastic molding solutions. Throughout this news article, we will explore the ongoing developments in plastic molding technology and delve into the capabilities of this leading company.1. The Evolution of Plastic Molding:The integration of advanced technologies has revolutionized the plastic molding industry, enhancing its efficiency, precision, and overall productivity. Traditional molding methods have been replaced by innovative techniques, with a strong focus on automation and computer-controlled processes. As a result, manufacturers are now able to produce complex and intricate plastic components with unmatched accuracy.2. Introduction to Prototype Plastic Molding:Prototype Plastic Molding, a globally recognized company, has been at the forefront of transforming the plastic molding landscape. With a strong emphasis on research and development, the company has consistently pushed the boundaries of manufacturing capabilities. They specialize in providing high-quality plastic parts to various industries such as automotive, electronics, medical, and consumer goods.3. Advanced Technologies:Prototype Plastic Molding has successfully adopted and integrated several advanced technologies within its manufacturing processes. The company utilizes computer-aided design (CAD) software to create precise digital models of the desired plastic components. These models are then translated into instructions for computer numerical control (CNC) machines, which enable the production of molds with extreme precision. Moreover, the company incorporates state-of-the-art 3D printing technologies to create prototypes before mass production, thereby ensuring the seamless development of new products.4. Enhanced Prototyping Capabilities:Through the utilization of their advanced CAD software and 3D printing technologies, Prototype Plastic Molding has elevated its prototyping capabilities. This enables their clients to visualize and assess the functionality, aesthetics, and ergonomics of their plastic components before final production begins. By streamlining the prototyping phase, the company diminishes the time and costs associated with product development, creating a competitive advantage for their clients.5. Emphasis on Sustainability:Prototype Plastic Molding maintains a strong commitment to sustainability, actively exploring ways to minimize waste and lower their environmental impact. The company utilizes recycled materials whenever possible, while also developing innovative solutions to optimize material usage. By implementing sustainable practices and adhering to stringent quality control measures, they ensure eco-friendly production while simultaneously meeting the evolving demands of the market.6. Cutting-edge Equipment and Expertise:Prototype Plastic Molding continuously invests in cutting-edge machinery and equipment to enhance their manufacturing capabilities. With a team of experienced professionals, they oversee every step of the production process, adhering to strict quality control standards. This holistic approach guarantees the delivery of excellent results while maintaining a rapid turnaround time for their customers.Conclusion:The advancements in plastic molding technology, spearheaded by companies like Prototype Plastic Molding, are revolutionizing the manufacturing sector. With their innovative techniques, commitment to sustainability, and expertise in delivering high-quality plastic components, Prototype Plastic Molding has earned a commendable reputation in the industry. As the manufacturing industry continues to evolve, plastic molding is expected to play an increasingly significant role, shaping the future of numerous sectors.

Revolutionary Moulding Maker: A Game-Changer in the Industry

Title: Revolutionary Moulding Maker Revolutionizes Manufacture ProcessesIntroduction:In the ever-evolving world of manufacturing, innovation plays a crucial role in improving productivity, reducing costs, and enhancing product quality. One exceptional company making waves in the industry is a renowned moulding maker, leveraging cutting-edge technologies to bring about a new era of manufacturing efficiency and precision. This article explores the groundbreaking solutions offered by this industry leader and examines how they are transforming manufacturing processes worldwide.Unveiling Revolutionary Manufacturing Solutions:With a rich history of innovation spanning several decades, this pioneering moulding maker has consistently pushed the boundaries of manufacturing capabilities. Their extensive range of moulding machines is known for its exceptional precision, reliability, and efficiency. By combining advanced technologies with a deep understanding of customer needs, this company has become a go-to partner for manufacturers across various sectors.Industry-Leading Technologies:Central to this moulding maker's success is their commitment to employing cutting-edge technologies. From advanced robotics to real-time monitoring systems, their moulding machines are equipped with state-of-the-art features that optimize production processes. These technologies allow manufacturers to achieve unparalleled levels of accuracy and speed, resulting in higher quality products and a significant reduction in waste.Enhanced Productivity and Efficiency:With the introduction of their innovative moulding machines, this industry leader has revolutionized the way manufacturers operate. By harnessing the power of automation, these machines streamline production lines, eliminating human error and maximizing efficiency. The integration of advanced robotics enables seamless material handling, precise moulding, and efficient packaging, significantly increasing production output while reducing labor costs.Exceptional Precision and Quality:Manufacturers worldwide strive to deliver products that meet the most stringent quality standards. This moulding maker delivers on these expectations by providing unparalleled precision and consistency. Equipped with sophisticated sensors and intelligent software, their machines ensure that every part produced is within specified tolerances, reducing the risk of defects and rejections. As a result, manufacturers can confidently offer customers products of uncompromising quality and reliability.Flexibility for Diverse Manufacturing Needs:Recognizing the unique requirements of different industries, this moulding maker offers a range of machines tailored to meet diverse manufacturing needs. Whether the industry demands high-volume production, intricate designs, or specialty materials, this company provides customized solutions that can accommodate various production scenarios. This flexibility allows manufacturers to adapt quickly to changing market demands and maintain a competitive edge in today's fast-paced business environment.Commitment to Sustainability:In an era where environmental concerns are at the forefront, this moulding maker has dedicated significant resources to develop eco-friendly manufacturing solutions. By minimizing energy consumption, optimizing material usage, and reducing waste generation, they help manufacturers achieve sustainability goals without compromising productivity or product quality. Through such initiatives, this company showcases its commitment to building a greener future for the manufacturing industry.Global Impact:This moulding maker's revolutionary solutions have made a significant impact on manufacturers worldwide. Their machines have been adopted by companies across various sectors, from automotive and electronics to consumer goods and medical devices. Their commitment to constant innovation and customer-centric approach has solidified their position as a trusted partner in driving manufacturing excellence.Conclusion:In a rapidly evolving manufacturing landscape, this moulding maker stands out as a true pioneer. Their emphasis on advanced technologies, precision, efficiency, and sustainability has reshaped the way products are made. By providing manufacturers with cutting-edge moulding machines, this industry leader continues to pave the way for increased productivity, improved quality, and a greener future. As global manufacturing demands continue to evolve, this moulding maker remains dedicated to supporting manufacturers in their pursuit of manufacturing excellence.

Custom Injection Molding Services for Precision Parts

A leading manufacturer and supplier of precision molded plastic components, based in the heart of the Midwest, has recently announced a significant expansion to its operations. With a strong reputation for delivering high-quality, custom-engineered products for a wide range of industries, the company is set to further solidify its position as a key player in the plastic molding industry.Precision Molding Inc. has been a stalwart in the plastic molding industry for over two decades, offering a comprehensive suite of services that cater to the unique needs and specifications of its diverse customer base. Specializing in the production of precision components for industries such as automotive, aerospace, medical devices, and consumer goods, the company has made a name for itself by consistently delivering innovative solutions and unparalleled quality to its clients.The recent expansion of Precision Molding Inc.'s operations comes as a result of the company's strong growth trajectory and increasing demand for its products and services. This expansion will see the addition of state-of-the-art machinery and equipment, as well as the hiring of a significant number of new employees to support the company's increased production capacity. With this expansion, Precision Molding Inc. aims to further enhance its ability to meet and exceed the expectations of its customers, while continuing to drive innovation and technological advancement within the industry.One of the key factors behind Precision Molding Inc.'s success and continued growth is its unwavering commitment to investing in cutting-edge technology and equipment. The company's dedication to staying at the forefront of industry advancements has allowed it to consistently deliver superior products that meet the highest standards of quality and precision. By expanding its capabilities and investing in the latest machinery, Precision Molding Inc. will be able to offer an even broader range of services and solutions to its customers, further solidifying its position as a leader in the plastic molding industry.In addition to its focus on technology and innovation, Precision Molding Inc. prides itself on its commitment to providing exceptional customer service and fostering strong, long-lasting relationships with its clients. The company's team of experienced professionals works closely with customers to understand their specific needs and requirements, offering tailored solutions that meet their unique specifications. This customer-centric approach has been instrumental in the company's success and has helped to solidify its reputation as a trusted and reliable partner for businesses across a wide range of industries.With its expanded operations, Precision Molding Inc. is not only poised to meet the growing demand for its products and services but is also well-positioned to take advantage of new opportunities for growth and expansion. The company's investment in state-of-the-art equipment and the addition of new talent to its team will enable it to further enhance its capabilities and bring even more value to its customers. By continuing to prioritize innovation, quality, and customer satisfaction, Precision Molding Inc. is set to remain at the forefront of the plastic molding industry for years to come.As the company looks towards the future, it remains committed to upholding its core values and delivering on its promise to provide exceptional products and services to its customers. With its expanded operations and continued dedication to innovation, Precision Molding Inc. is well-positioned to continue its trajectory of growth and success, solidifying its position as a leader in the plastic molding industry.

Understanding the Process and Advantages of PVC Blow Molding

PVC Blow Molding Company Leads the Industry with Innovative TechnologyWith the global market for plastic blow molding projected to reach $71 billion by 2025, it's essential for companies in the industry to stay ahead of the curve with innovative technology and cutting-edge processes. One company that is leading the way in this regard is [Company Name], a top player in the PVC blow molding sector.Established in [year], [Company Name] has built a reputation for excellence in the industry, known for its commitment to quality, innovation, and customer satisfaction. The company specializes in the production of complex, high-quality PVC blow molding products for a wide range of industries, including automotive, medical, consumer goods, and more.One of the key factors that sets [Company Name] apart from its competitors is its dedication to leveraging the latest technological advancements in the blow molding process. The company has heavily invested in state-of-the-art equipment and machinery to ensure that it remains at the forefront of the industry. This commitment to innovation has allowed [Company Name] to consistently deliver superior quality products to its customers while maintaining efficient production processes.In a recent development, [Company Name] has introduced a groundbreaking new technology that is set to revolutionize the PVC blow molding industry. The company has invested in cutting-edge R&D to develop a proprietary method that allows for the production of PVC products with unprecedented precision, consistency, and efficiency. This new technology not only enhances the overall quality of the products but also significantly reduces production costs, making [Company Name] even more competitive in the market.Furthermore, the new technology has also allowed [Company Name] to expand its product offerings, catering to a wider range of customer needs and requirements. This strategic move has positioned the company as a one-stop solution for all PVC blow molding needs, further solidifying its standing as an industry leader.In addition to its technological innovation, [Company Name] is also committed to sustainability and environmental responsibility. The company has implemented various initiatives to minimize its environmental impact, such as energy-efficient production processes, waste reduction strategies, and the use of eco-friendly materials. By prioritizing sustainability, [Company Name] not only contributes to a greener planet but also meets the growing demand for environmentally friendly products in the market.Customer satisfaction remains a top priority for [Company Name], and the company goes above and beyond to ensure that its clients receive the highest quality products and services. With a team of experienced professionals, [Company Name] provides personalized support to its customers, from the initial design phase to final product delivery. The company's dedication to customer service has earned it a loyal customer base and numerous long-term partnerships with leading brands across various industries.Looking ahead, [Company Name] is poised for continued growth and success in the PVC blow molding industry. By staying at the forefront of technological innovation, maintaining a strong commitment to sustainability, and prioritizing customer satisfaction, the company is well-positioned to capitalize on the growing demand for high-quality PVC blow molding products.In conclusion, [Company Name] is setting a new standard for excellence in the PVC blow molding industry. With its innovative technology, commitment to sustainability, and unwavering dedication to customer satisfaction, the company is primed to lead the industry into the future. As the demand for PVC blow molding products continues to rise, [Company Name] is well-equipped to meet the needs of a diverse and ever-expanding market.

Exploring the Efficiency and Advantages of Plastic Blow Molding

Plastic Blow Molding – The Future of ManufacturingIn today’s world, plastic has become an indispensable part of our lives. From disposable water bottles to complex machinery parts, plastic is used in almost every aspect of our daily routine. However, the process of producing high-quality plastic products requires sophisticated techniques and expensive machinery.This is where Plastic Blow Molding comes in. Plastic blow molding is a manufacturing process that involves the use of blow molding machines to mold plastic into various shapes and sizes. The process is widely used in the production of bottles, containers, and other types of plastic products.One company that has established itself as a leader in the field of plastic blow molding is a well-known company. The company has been providing high-quality blow-molded products for over 20 years and has become a trusted name in the industry.The company boasts state-of-the-art facilities and a team of experienced professionals who are dedicated to producing top-quality plastic products. Their advanced machinery allows for the production of various types of plastic products, ranging from small containers to large industrial tanks.One of the key benefits of plastic blow molding is its versatility. The process allows for the production of complex shapes and designs that would otherwise be impossible to achieve with traditional molding techniques. The end product is strong, durable, and lightweight, making it ideal for use in various industries, including automotive, construction, and packaging.Moreover, plastic blow molding is an eco-friendly process as it requires minimal energy and produces little to no waste. The process also uses recycled materials, which helps to reduce environmental impact and conserve resources.Another benefit of plastic blow molding is its cost-effectiveness. The process requires less labor and produces a higher yield than traditional molding techniques, making it a more cost-effective option for businesses.The company has also implemented strict quality control measures to ensure that every product meets the highest standards. This includes rigorous testing of raw materials, in-process inspection, and final product testing. With a commitment to quality and customer satisfaction, the company has established a loyal customer base and a reputation for excellence.In addition to providing high-quality products, the company also offers a range of services to its clients. This includes product design and development, prototyping, and custom molding. They work closely with clients to understand their needs and provide customized solutions that meet their requirements.Overall, plastic blow molding is a highly effective and versatile manufacturing process that has revolutionized the industry. With the help of companies like the one discussed, businesses can take advantage of the benefits of plastic blow molding and produce top-quality plastic products at a reasonable cost.In conclusion, with advancements in technology and an increasing demand for plastic products, the future of plastic blow molding looks bright. The industry is set to expand in the coming years, and companies like the one discussed will continue to play a crucial role in the growth and development of the industry.

Optimizing Part Production with Gas Assisted Injection Molding

Gas Assisted Molding Technology Takes the Automotive Industry by StormThe global automotive industry has been revolutionized by research and development of innovative production technologies that are not only efficient but also cost-effective. One of the most significant breakthroughs in the industry is Gas Assisted Molding Technology (GAM), which has enabled manufacturing processes to produce lighter and stronger parts for vehicles. GAM technology has been widely accepted by leading automakers to create cost-effective, high-quality, and innovative products.As an active player in the automotive industry, a leading Chinese automotive gas-assisted molding technology provider (need to remove the brand name), has taken the forefront in developing advanced technologies to help automakers create cost-effective and high-quality products. Gas Assisted Molding Technology is a new way of manufacturing hollow parts, which uses gas pressure to create the required geometry. The technology molds the plastic parts by injecting molten plastic into a hollow mold cavity and then introducing inert nitrogen gas into the core of the melted plastic.The inserted gas displaces the plastic from the position of the free surface, reduces flow resistance, and controls the plastic flow. As the cavity fills with plastic, the gas pressure pushes the molten material to the far reaches of the mold cavity. This results in an even wall thickness that translates into superior product strength and quality.Over the years, the technology has increasingly become popular among automakers, due to its ability to produce high-quality products with fewer raw materials, making it more cost-effective than traditional molding technologies. GAM technology has been widely adopted to improve the quality of plastic components used in the automotive industry. The lighter and stronger parts produced by GAM technology result in a reduction in weight and enhanced fuel efficiency, which is ideal for electric and hybrid vehicles.A key feature of the technology is that it allows designers and engineers to create complex shapes, which are popular among automakers. The unique shapes are essential in creating modern designs, which are not only aesthetically pleasing but also functional.The use of GAM technology in manufacturing has increased rapidly due to the many benefits it offers. One of the main benefits of the technology is that it enables faster cycle times, leading to an increase in productivity and reduced manufacturing costs. The technology also eliminates the need for welding or gluing, which is costly and time-consuming, making it the most cost-effective method for manufacturing large complex parts.GAM technology is also vital in achieving consistent product quality, which is essential in the automotive industry. The process provides better dimensional accuracy, thus reducing the chances of defects arising in the final product. The result is a higher quality and defect-free product that meets the high expectations of the automotive consumers.The widespread use of GAM technology in the automotive industry has led to a significant reduction in environmental footprint. The technology uses fewer raw materials, resulting in less waste, and lower greenhouse gas emissions.The high demand for GAS technology in the automotive sector has led to its adoption in other industries, such as medical device manufacturing, furniture, and sports equipment. This is because the technology allows for the creation of hollow parts with complex geometries that are lightweight, strong and aesthetically pleasing. The versatility of the technology makes it ideal for any industry that requires high-quality plastic products.In conclusion, Gas Assisted Molding Technology has rapidly transformed the way the automotive industry operates. GAM technology provides designers and engineers with a unique tool that enables them to create high-quality products with complex geometries. This technology offers numerous benefits, including cost-effectiveness, faster cycle times, improved quality, and reduced environmental footprint. As the industry continues to evolve, it is expected that GAM technology will become an even more vital tool for manufacturing innovative and efficient products.