High-Quality Metal Molds for Plastic Injection

By:Admin

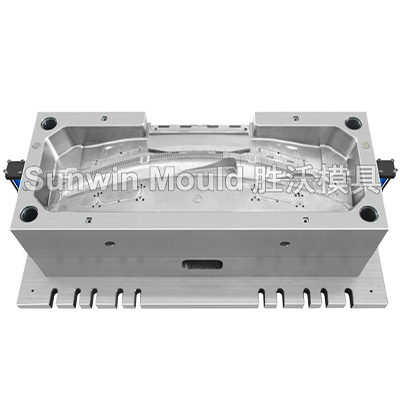

In the ever-evolving world of manufacturing, the use of metal molds for plastic has become a crucial component in the production of various consumer goods. These metal molds play a vital role in shaping and creating intricate and precise plastic components. The demand for high-quality metal molds has led to the rise of innovative companies such as **(brand name removed)**, a leading manufacturer in the industry.

**(Brand name removed)** has established itself as a premier provider of metal molds for plastic, offering a wide range of products and services to meet the diverse needs of its clients. With a strong focus on quality, precision, and customer satisfaction, the company has earned a reputation for excellence in the field of plastic mold manufacturing.

The company's success can be attributed to its state-of-the-art manufacturing facilities, cutting-edge technology, and a team of highly skilled engineers and technicians. The use of advanced machinery and equipment allows **(brand name removed)** to produce metal molds with unparalleled precision and accuracy, ensuring the highest level of quality in every product.

Furthermore, **(brand name removed)**'s commitment to innovation and continuous improvement has enabled it to stay ahead of the curve in an ever-changing industry. The company invests heavily in research and development, constantly seeking new and improved methods for mold design and production. This dedication to innovation has led to the creation of groundbreaking metal molds that offer superior performance and durability.

One of the key advantages of using metal molds for plastic is their ability to withstand high temperatures and pressures during the molding process. Unlike traditional plastic molds, metal molds are capable of producing parts with tighter tolerances and finer details, resulting in higher-quality finished products. This makes them an ideal choice for industries such as automotive, electronics, medical devices, and consumer goods.

Moreover, metal molds are known for their longevity and resistance to wear and tear, making them a cost-effective solution for long-term production needs. With proper maintenance and care, metal molds can last for thousands of injection cycles, making them a wise investment for any manufacturing operation.

In addition to its extensive range of standard mold offerings, **(brand name removed)** also specializes in custom mold design and fabrication. The company works closely with clients to understand their unique requirements and specifications, leveraging its expertise to create tailor-made solutions that meet their exact needs.

As part of its comprehensive services, **(brand name removed)** also provides technical support, maintenance, and repair services for its metal molds. This ensures that clients can maximize the lifespan and performance of their molds, ultimately leading to increased efficiency and productivity in their manufacturing processes.

The use of metal molds for plastic has revolutionized the way various industries approach the production of plastic components. **(brand name removed)** has been at the forefront of this technological advancement, providing cutting-edge solutions to meet the ever-growing demand for high-quality plastic parts.

With a solid track record of excellence, innovation, and customer satisfaction, **(brand name removed)** continues to set the standard for metal mold manufacturing. The company's unwavering commitment to quality and precision makes it a trusted partner for businesses looking to enhance their manufacturing processes and stay ahead in a competitive market.

In conclusion, the use of metal molds for plastic represents a significant advancement in the manufacturing industry, offering unparalleled precision, durability, and cost-effectiveness. As a leading manufacturer in this field, **(brand name removed)** has demonstrated its ability to deliver top-tier products and services, solidifying its position as an industry leader. With its dedication to innovation and customer satisfaction, **(brand name removed)** is poised to shape the future of plastic mold manufacturing and continue its legacy of excellence.

Company News & Blog

High-quality Plate Mould for Efficient Production

Plate Mould, a leading manufacturer of high-quality automotive and household moulds, has announced the launch of their latest product line. The company, which has been a trusted name in the industry for over 20 years, has built a strong reputation for producing durable and precise moulds for a wide range of applications.Plate Mould's state-of-the-art manufacturing facility is equipped with the latest technology and machinery, allowing them to produce moulds that meet the highest standards of quality and precision. Their team of experienced engineers and technicians work tirelessly to ensure that each mould is designed and manufactured to the exact specifications of their customers.The company's dedication to providing superior products and outstanding customer service has earned them a loyal customer base and a solid reputation within the industry. Their commitment to innovation and continuous improvement is evident in the performance and reliability of their moulds.Plate Mould's latest product line features a range of automotive and household moulds that have been carefully designed to meet the needs of their customers. From automotive parts to household appliances, the company's moulds are trusted by leading manufacturers and businesses around the world.In addition to their standard product line, Plate Mould also offers custom mould design and manufacturing services. Their experienced team works closely with customers to understand their specific requirements and develop moulds that meet their exact needs. Whether it's a unique automotive part or a custom household appliance, Plate Mould has the knowledge and expertise to bring their customers' visions to life.Plate Mould's commitment to quality and precision is evident in every aspect of their business. From the initial design phase to the final manufacturing process, the company takes great care to ensure that each mould meets their rigorous standards. This dedication to excellence has set them apart from their competitors and positioned them as a leader in the industry.With the launch of their latest product line, Plate Mould continues to demonstrate their commitment to innovation and quality. The new moulds are designed to provide superior performance and durability, allowing their customers to achieve excellent results in their manufacturing processes.Plate Mould's products are trusted by some of the biggest names in the automotive and household appliance industries, and their latest product line is expected to further solidify their position as a trusted provider of high-quality moulds. The company's dedication to excellence and customer satisfaction sets them apart from their competitors and reinforces their reputation as a leader in the industry.Plate Mould's latest product line is now available for purchase, and the company is excited to offer their customers access to their innovative and high-quality moulds. With their dedication to excellence and their commitment to customer satisfaction, Plate Mould continues to set the standard for quality and precision in the industry.

Discover the Benefits of Large Plastic Moulds for Your Business

Insert Large Plastic Mould, a leading manufacturer in the plastic molding industry, has recently achieved a major milestone with the development of a new large plastic mould. This breakthrough has cemented the company's position as a pioneer in the field of plastic moulding technology and has set a new standard for the industry.The new large plastic mould has been designed and manufactured to meet the growing demand for high-quality, large-scale plastic products. With a focus on precision engineering and advanced materials, the mould is capable of producing large plastic components with exceptional accuracy and consistency. This cutting-edge technology is set to revolutionize the way large plastic products are manufactured, offering significant improvements in efficiency, speed, and quality.Insert Large Plastic Mould has a long-standing reputation for excellence in the plastic molding industry. With over 20 years of experience, the company has continually pushed the boundaries of what is possible with plastic moulding technology. Their team of experienced engineers and designers are dedicated to innovation and are committed to delivering solutions that exceed the expectations of their clients.The development of the new large plastic mould is a testament to Insert Large Plastic Mould's ongoing commitment to research and development. The company has invested heavily in state-of-the-art equipment and facilities to ensure that they remain at the forefront of the industry. By staying ahead of the curve, Insert Large Plastic Mould is able to offer its clients the most advanced and reliable plastic moulding solutions available.The introduction of the new large plastic mould is expected to have a significant impact on the industry. With its advanced capabilities and unparalleled precision, the mould will enable manufacturers to produce large plastic products with greater efficiency and accuracy than ever before. This will not only streamline production processes but also improve the overall quality of large plastic components.As a result of this groundbreaking development, Insert Large Plastic Mould has already received significant interest from clients and partners within the industry. The company's commitment to excellence and innovation has positioned them as a preferred partner for businesses looking to leverage the latest advancements in plastic moulding technology. This new large plastic mould is expected to open up new opportunities for Insert Large Plastic Mould, allowing them to expand their reach and impact within the market.In addition to the new large plastic mould, Insert Large Plastic Mould continues to offer a comprehensive range of plastic moulding solutions for a wide variety of applications. From small, intricate components to large, complex parts, the company has the expertise and technology to meet the needs of any project. Their commitment to quality, precision, and customer satisfaction has earned them a solid reputation as a trusted leader in the industry.Ultimately, Insert Large Plastic Mould's continued success and industry leadership can be attributed to their relentless pursuit of excellence. By investing in cutting-edge technology and fostering a culture of innovation, the company has set itself apart as a trailblazer in the plastic moulding industry. The introduction of the new large plastic mould is just the latest example of Insert Large Plastic Mould's unwavering commitment to pushing the boundaries of what is possible with plastic moulding.

Top Suppliers of Perfume Molds in China

China Perfume Mold Suppliers Join Forces to Expand Global MarketIn a strategic move to expand their reach and increase their presence in the global market, a group of China-based perfume mold suppliers have joined forces to form a powerful alliance. This move comes at a time when the demand for high-quality perfume molds is on the rise, driven by the growing consumer interest in personal care and beauty products.The new alliance, comprised of several leading perfume mold suppliers, aims to capitalize on the booming demand for perfume molds and accessories in the international market. By pooling their resources and expertise, the members of the alliance seek to enhance their collective capabilities and offer a wider range of products and services to their global customers.One of the key players in this alliance is a well-established company that has been a leading supplier of perfume molds and accessories in China for over two decades. With a track record of delivering high-quality products and unparalleled customer service, this company has earned a solid reputation as a trusted partner in the perfume manufacturing industry.The company specializes in the design, development, and production of a wide range of perfume molds, including bottle molds, cap molds, and pump molds. Their state-of-the-art manufacturing facilities are equipped with the latest technology and advanced machinery, allowing them to produce precision molds that meet the exact specifications of their clients.In addition to their manufacturing capabilities, the company also offers comprehensive mold customization services, working closely with their clients to develop bespoke solutions that meet their specific requirements. With a strong focus on quality and innovation, the company is committed to delivering superior products that meet the highest industry standards.By joining forces with other leading perfume mold suppliers, this company aims to leverage its expertise and resources to expand its global market reach. Through the alliance, the company will be able to tap into new market opportunities and gain access to a wider network of customers and partners around the world.The alliance also provides the company with a platform to showcase its latest products and innovations at international trade shows and industry events. By participating in these events as a unified entity, the members of the alliance can present a stronger and more comprehensive offering to potential customers, enhancing their visibility and credibility in the global market.Furthermore, the alliance will enable the company to benefit from collective marketing initiatives and promotional activities, allowing them to amplify their brand presence and generate greater awareness for their products and services. By pooling their marketing efforts, the members of the alliance can maximize their impact and reach a larger audience of potential customers.In addition to expanding their global market presence, the alliance also aims to foster collaboration and knowledge sharing among its members. By working closely with other industry leaders, the company can gain valuable insights and best practices that will further enhance its capabilities and competitiveness in the market.Ultimately, the formation of this alliance represents a significant milestone for the perfume mold industry in China, signaling a new era of collaboration and growth. With a shared vision of expanding their global footprint and delivering exceptional products and services to customers worldwide, the members of the alliance are poised to make a significant impact on the international perfume manufacturing industry.As the demand for high-quality perfume molds continues to rise, the alliance is well-positioned to capitalize on this trend and establish itself as a leading force in the global market. With their combined expertise, resources, and commitment to excellence, the members of the alliance are set to shape the future of the perfume mold industry and redefine the standards for quality and innovation in the market.

Durable Metal Molds for Plastic Manufacturing: A Cost-Effective Solution

Metal Molds For PlasticMetal molds for plastics are essential tools in the manufacturing industry, playing a crucial role in the production of various plastic products. These molds are used to shape and produce plastic parts and products through the process of injection molding. The quality and precision of these molds are paramount to the production of high-quality plastic products.One company that has been at the forefront of producing high-quality metal molds for plastics is {}. With years of experience and expertise in the field, they have established themselves as a trusted and reliable supplier of metal molds for plastic to various industries.Established in {}, {} has been a leading manufacturer of metal molds for plastic, serving a wide range of industries including automotive, electronics, consumer goods, and more. Their state-of-the-art facilities and advanced manufacturing capabilities allow them to produce metal molds with exceptional precision and quality.The company specializes in the design and production of custom metal molds for plastic, catering to the specific needs and requirements of their clients. Whether it is complex geometric shapes, intricate designs, or tight tolerances, {} has the expertise and technology to deliver molds that meet the highest standards.Their team of highly skilled engineers and technicians work closely with clients to understand their unique requirements and provide custom mold solutions that are tailored to their specific applications. From the initial design and engineering phase to the final production and delivery, {} ensures that every step of the process is carried out with the utmost attention to detail and quality.In addition to custom mold manufacturing, {} also offers mold repair and maintenance services to ensure the longevity and performance of their molds. Their comprehensive approach to mold maintenance helps clients maximize the lifespan of their molds and minimize downtime in their production processes.With a commitment to innovation and continuous improvement, {} continually invests in research and development to stay at the forefront of mold manufacturing technology. This allows them to offer advanced mold solutions that incorporate the latest advancements in materials, design, and manufacturing techniques.Furthermore, {} is dedicated to upholding the highest standards of quality and safety in their manufacturing processes. Their facilities are equipped with advanced quality control systems to ensure that every mold meets the strictest quality standards before it is delivered to the client.As a result of their dedication to excellence and customer satisfaction, {} has built a strong reputation in the industry as a trusted supplier of metal molds for plastic. Their commitment to delivering high-quality, custom mold solutions has earned them the trust and loyalty of a wide range of clients from various industries.In conclusion, metal molds for plastic play a crucial role in the production of high-quality plastic products, and {} has proven to be a leader in the manufacturing of these molds. With their expertise, advanced capabilities, and commitment to quality, they continue to be a preferred partner for clients seeking custom metal molds for their plastic production needs.

High-Quality Pallet Box Moulds for Effective Storage and Transportation

Pallet Box Mould, a leader in the manufacturing of high-quality injection molds, is proud to announce the introduction of their latest innovative product. The company has been at the forefront of the industry for many years, providing cutting-edge solutions for a wide range of industries. With their dedication to quality, precision, and customer satisfaction, Pallet Box Mould has established themselves as a trusted name in the industry.The new product, which has been in development for several months, is a state-of-the-art pallet box mould that is designed to meet the diverse needs of their clients. The mould is manufactured using the latest technology and techniques, ensuring superior quality and durability. It is suitable for the production of various types of pallet boxes, which are widely used for storage, transportation, and logistics purposes.One of the key features of the new pallet box mould is its versatility. It is capable of producing a wide range of box sizes and designs, making it an ideal solution for companies with diverse needs. This flexibility allows companies to streamline their production processes and adapt to changing market demands. Additionally, the mould is designed for high-speed production, helping companies to meet tight deadlines and maximize efficiency.Furthermore, the pallet box mould is engineered to deliver consistent and precise results. This ensures that every moulded box is of the highest quality, with uniform dimensions and structural integrity. This level of precision is essential for businesses that require dependable and resilient pallet boxes to protect their goods during storage and transit.In addition to its technical capabilities, the new pallet box mould is also designed with user-friendliness in mind. The mould features easy-to-use controls and a user-friendly interface, allowing operators to set up and operate the equipment with minimal training. This helps to reduce downtime and improve overall productivity."We are thrilled to introduce our latest pallet box mould to the market," said the spokesperson for Pallet Box Mould. "This product is the result of our ongoing commitment to innovation and quality. We have leveraged our extensive experience and expertise to develop a mould that meets the evolving needs of our clients. We are confident that this product will provide tremendous value to businesses across various industries."Pallet Box Mould is well-equipped to support the introduction of their new product. The company boasts a team of highly skilled engineers, technicians, and quality control experts who work tirelessly to ensure that every mould meets the highest standards. Additionally, their state-of-the-art manufacturing facility is equipped with advanced machinery and cutting-edge technology, enabling them to produce top-of-the-line moulds with efficiency and precision.Moreover, Pallet Box Mould is committed to providing exceptional customer service and support. They work closely with their clients to understand their specific requirements and to deliver custom solutions that address their unique needs. Their dedication to customer satisfaction has earned them a sterling reputation in the industry, with many clients relying on them as their go-to partner for all their moulding needs.In conclusion, Pallet Box Mould's new pallet box mould is a testament to their ongoing pursuit of excellence and innovation. With its advanced features, superior quality, and user-friendly design, this mould is set to make a significant impact in the market. Coupled with the company's strong reputation, expertise, and commitment to customer satisfaction, Pallet Box Mould is well-positioned to continue leading the industry and providing valuable solutions to businesses worldwide.

Custom Injection Molding Services for Precision Parts

A leading manufacturer and supplier of precision molded plastic components, based in the heart of the Midwest, has recently announced a significant expansion to its operations. With a strong reputation for delivering high-quality, custom-engineered products for a wide range of industries, the company is set to further solidify its position as a key player in the plastic molding industry.Precision Molding Inc. has been a stalwart in the plastic molding industry for over two decades, offering a comprehensive suite of services that cater to the unique needs and specifications of its diverse customer base. Specializing in the production of precision components for industries such as automotive, aerospace, medical devices, and consumer goods, the company has made a name for itself by consistently delivering innovative solutions and unparalleled quality to its clients.The recent expansion of Precision Molding Inc.'s operations comes as a result of the company's strong growth trajectory and increasing demand for its products and services. This expansion will see the addition of state-of-the-art machinery and equipment, as well as the hiring of a significant number of new employees to support the company's increased production capacity. With this expansion, Precision Molding Inc. aims to further enhance its ability to meet and exceed the expectations of its customers, while continuing to drive innovation and technological advancement within the industry.One of the key factors behind Precision Molding Inc.'s success and continued growth is its unwavering commitment to investing in cutting-edge technology and equipment. The company's dedication to staying at the forefront of industry advancements has allowed it to consistently deliver superior products that meet the highest standards of quality and precision. By expanding its capabilities and investing in the latest machinery, Precision Molding Inc. will be able to offer an even broader range of services and solutions to its customers, further solidifying its position as a leader in the plastic molding industry.In addition to its focus on technology and innovation, Precision Molding Inc. prides itself on its commitment to providing exceptional customer service and fostering strong, long-lasting relationships with its clients. The company's team of experienced professionals works closely with customers to understand their specific needs and requirements, offering tailored solutions that meet their unique specifications. This customer-centric approach has been instrumental in the company's success and has helped to solidify its reputation as a trusted and reliable partner for businesses across a wide range of industries.With its expanded operations, Precision Molding Inc. is not only poised to meet the growing demand for its products and services but is also well-positioned to take advantage of new opportunities for growth and expansion. The company's investment in state-of-the-art equipment and the addition of new talent to its team will enable it to further enhance its capabilities and bring even more value to its customers. By continuing to prioritize innovation, quality, and customer satisfaction, Precision Molding Inc. is set to remain at the forefront of the plastic molding industry for years to come.As the company looks towards the future, it remains committed to upholding its core values and delivering on its promise to provide exceptional products and services to its customers. With its expanded operations and continued dedication to innovation, Precision Molding Inc. is well-positioned to continue its trajectory of growth and success, solidifying its position as a leader in the plastic molding industry.

High-quality 4 Cavity Blow Moulding Machine for Efficient Production

4 Cavity Blow Moulding Machine Revolutionizes Plastic Packaging ProductionIn a significant development for the plastic packaging industry, the latest 4 cavity blow moulding machine has been introduced by {} to revolutionize the production process. With its cutting-edge technology and innovative design, this machine is set to redefine the way plastic packaging is manufactured, offering enhanced efficiency, productivity, and cost-effectiveness.With the increasing demand for plastic packaging across various industries, there has been a growing need for advanced machinery that can meet the evolving requirements of production. The introduction of the 4 cavity blow moulding machine addresses this need by providing a highly efficient and versatile solution for the manufacturing of plastic bottles, containers, and other packaging products.One of the key features of this machine is its capability to produce four bottles simultaneously, thereby increasing the production output and reducing the manufacturing time. This not only enhances the overall productivity of the production process but also leads to significant cost savings for the manufacturers. Additionally, the machine is equipped with cutting-edge technology that ensures the production of high-quality, uniform, and defect-free products, meeting the stringent standards of the industry.Furthermore, the 4 cavity blow moulding machine incorporates advanced automation and control systems, allowing for precise monitoring and adjustment of the production process. This ensures consistent product quality and minimizes the risk of errors or defects during the manufacturing process. The machine also offers a high degree of flexibility, allowing for quick and easy mold changes to accommodate different product specifications and designs.The introduction of this advanced machinery by {} reflects the company's commitment to innovation and excellence in the plastic packaging industry. With years of experience and expertise in the field, {} has established itself as a leading manufacturer and supplier of blow moulding machines and other plastic processing equipment. The introduction of the 4 cavity blow moulding machine is a testament to the company's dedication to providing cutting-edge solutions that meet the evolving needs of the industry."We are thrilled to introduce the latest 4 cavity blow moulding machine, which represents a significant leap forward in plastic packaging production," said a spokesperson for {}. "This machine is the result of our relentless pursuit of innovation and our commitment to meeting the demands of the industry. We believe that this machine will not only enhance the production capabilities of our customers but also contribute to the overall advancement of the plastic packaging sector."The introduction of the 4 cavity blow moulding machine is poised to have a transformative impact on the plastic packaging industry, offering manufacturers a competitive edge through enhanced efficiency, productivity, and quality. As the demand for plastic packaging continues to grow, advanced machinery such as this will play a crucial role in meeting the industry's evolving needs and driving its future growth and development.With its advanced technology, innovative design, and commitment to excellence, the 4 cavity blow moulding machine by {} is set to shape the future of plastic packaging production, offering manufacturers a powerful tool to meet the demands of the market and stay ahead in the competitive landscape.

Understanding the Process of Injection Blow Molding

Injection Blow Molding (IBM) is a manufacturing process used to produce hollow plastic parts. It is widely utilized in various industries such as packaging, automotive, and medical devices. The process involves injecting melted thermoplastic resin into a mold cavity to form a parison. Then, a blow pin is inserted into the parison to inflate and form the hollow part.In recent years, the demand for high-quality plastic products has been on the rise, driving the adoption of advanced manufacturing technologies like Injection Blow Molding. One company that has been at the forefront of IBM technology is {}. With state-of-the-art facilities and a team of experienced professionals, they have established themselves as a leading provider of Injection Blow Molding solutions.{} has a proven track record of delivering innovative and reliable IBM products to their clients. They offer a wide range of services including designing, prototyping, and production of custom molds for various applications. The company's commitment to quality and customer satisfaction has earned them a loyal customer base and a solid reputation in the industry.One of the key advantages of Injection Blow Molding is its ability to produce complex and precise parts with high accuracy and repeatability. With the use of advanced technology and extensive expertise, {} is able to meet the strictest tolerances and quality standards required by their customers. This allows them to cater to the diverse needs of different industries, including pharmaceutical packaging, personal care products, and automotive components.Furthermore, {}. has been investing in continuous research and development to enhance their IBM capabilities. By staying ahead of the curve, they are able to offer cutting-edge solutions to their clients, enabling them to stay competitive in their respective markets. The company's commitment to innovation and technological advancement has been a driving force behind their success.Another strength of {} lies in their focus on sustainability and environmental responsibility. They have implemented eco-friendly practices in their manufacturing processes, such as using recycled materials and optimizing energy efficiency. By doing so, they are able to minimize their impact on the environment while providing sustainable solutions to their customers.In addition to their impressive technical capabilities, {}. takes pride in their commitment to exceptional customer service. Their team of experts works closely with clients throughout the entire manufacturing process, from initial concept to final product delivery. They understand the importance of clear communication and collaboration to ensure that the end result meets or exceeds the client's expectations.Looking ahead, {}. is poised for continued growth and success in the field of Injection Blow Molding. With a strong focus on quality, innovation, and customer satisfaction, they are well-positioned to capitalize on the growing demand for high-quality plastic products. Their dedication to excellence and continuous improvement sets them apart as a top-tier provider of IBM solutions.In conclusion, Injection Blow Molding is a crucial manufacturing process that plays a pivotal role in the production of various plastic parts. {}. has demonstrated leadership in this field, delivering superior IBM solutions to a diverse range of industries. With their technical expertise, commitment to sustainability, and dedication to customer service, they are well-equipped to meet the evolving needs of the market and continue their success in the years to come.

Affordable Vegetable Crate Mould Manufacturer Sheds Light on the Industry

In the world of manufacturing, technology and innovation go hand in hand with quality and safety. And for companies that specialize in creating molds for plastic products, this is especially true. One such company that has made a name for itself as a premier manufacturer of high-quality molds is Cheap Vegetable Crate Mould Manufacturer.Based in China, Cheap Vegetable Crate Mould Manufacturer has been in the business of producing molds since 1998. Over the years, the company has grown in size and reputation, thanks to its commitment to excellence in everything it does. With a team of experienced and highly skilled professionals, Cheap Vegetable Crate Mould Manufacturer is dedicated to providing its clients with the best possible solutions for their needs.One of the areas in which Cheap Vegetable Crate Mould Manufacturer excels is in the creation of molds for vegetable crates. These crates are an essential tool in the agriculture industry, used for transporting and storing produce. As such, they need to be durable, reliable, and able to withstand the rigors of everyday use. And this is where Cheap Vegetable Crate Mould Manufacturer comes in.With years of experience in the field, Cheap Vegetable Crate Mould Manufacturer has developed a deep understanding of what it takes to create molds that meet the needs of the agriculture industry. From design to production, the company is committed to delivering high-quality molds that are not only effective but also cost-effective for its customers.In addition to its focus on vegetable crate molds, Cheap Vegetable Crate Mould Manufacturer offers a wide range of other products and services. These include molds for plastic chairs, pallets, buckets, and more. The company also provides customization services, allowing clients to create molds that meet their specific requirements. And with a reputation for quality and reliability, Cheap Vegetable Crate Mould Manufacturer is the go-to choice for customers around the world.But what sets Cheap Vegetable Crate Mould Manufacturer apart from its competitors? According to the company, it is its dedication to quality and innovation. The team at Cheap Vegetable Crate Mould Manufacturer is constantly looking for ways to improve its products and services, using the latest technology and techniques to stay ahead of the curve. And with a commitment to customer satisfaction, the company is always ready and willing to go the extra mile to ensure that its clients are happy with their results.For customers in need of high-quality molds for their plastic products, Cheap Vegetable Crate Mould Manufacturer is the clear choice. With years of experience, expert knowledge, and a commitment to excellence, the company offers a comprehensive range of products and services that are designed to meet the needs of a wide variety of industries. And with a reputation for quality and reliability, Cheap Vegetable Crate Mould Manufacturer is poised to continue growing and expanding into the future.

Understanding the Importance of Top Cap Molding in Manufacturing Processes

Top Cap Molding, a leading manufacturer in the plastic molding industry, has been making waves with their top-of-the-line products and exceptional customer service. Established in 2005, the company has quickly risen to prominence, earning a stellar reputation within the industry for their high-quality molding solutions.Specializing in the production of top caps for a variety of industries, Top Cap Molding prides itself on their ability to provide custom molding services to meet the unique needs of their clients. With a state-of-the-art manufacturing facility and a team of highly skilled engineers and technicians, the company is able to deliver top-notch products that exceed industry standards.One of the key factors that sets Top Cap Molding apart from their competitors is their unwavering commitment to quality. The company places a strong emphasis on using the latest technology and the best materials in their manufacturing processes, ensuring that their products are durable, reliable, and built to last. In addition, their strict quality control measures guarantee that every product that leaves their facility meets the highest standards of excellence.Furthermore, Top Cap Molding is dedicated to providing exceptional customer service. The company takes a collaborative approach with their clients, working closely with them to understand their specific requirements and develop tailored solutions that meet their exact needs. Their responsive and knowledgeable sales team is always available to address any inquiries and provide guidance throughout the entire process, from initial consultation to final product delivery.In recent news, Top Cap Molding has announced the launch of a new line of top caps that are specifically designed to meet the growing demand for sustainable and eco-friendly packaging solutions. The company has invested heavily in research and development to create top caps that are made from recycled materials, without compromising on quality or performance. This new product line is a testament to Top Cap Molding's commitment to innovation and environmental responsibility."We are thrilled to introduce our new line of sustainable top caps," said the CEO of Top Cap Molding. "As a company, we recognize the importance of reducing our environmental footprint and offering eco-friendly alternatives to our clients. We believe that these new top caps will not only benefit the planet, but also provide our customers with a superior and sustainable packaging solution."The introduction of this new product line has been well-received by industry experts and customers alike, with many applauding Top Cap Molding for their forward-thinking approach and dedication to sustainability. The company's innovative efforts have positioned them as a leader in the industry, setting a new standard for eco-friendly packaging solutions.Looking ahead, Top Cap Molding is poised to continue its upward trajectory, with plans to further expand their product offerings and enhance their manufacturing capabilities. With a focus on excellence, innovation, and customer satisfaction, the company is well-positioned to remain a top contender in the plastic molding industry.In conclusion, Top Cap Molding has solidified its position as a premier manufacturer of top caps, delivering top-quality products and unparalleled customer service. Their recent launch of sustainable top caps underscores their commitment to environmental stewardship and sets a new benchmark for eco-friendly packaging solutions. With a steadfast dedication to quality and a progressive approach to innovation, Top Cap Molding is undoubtedly a force to be reckoned with in the industry.