High-Quality Plastic Molding Services for Precision Results

By:Admin

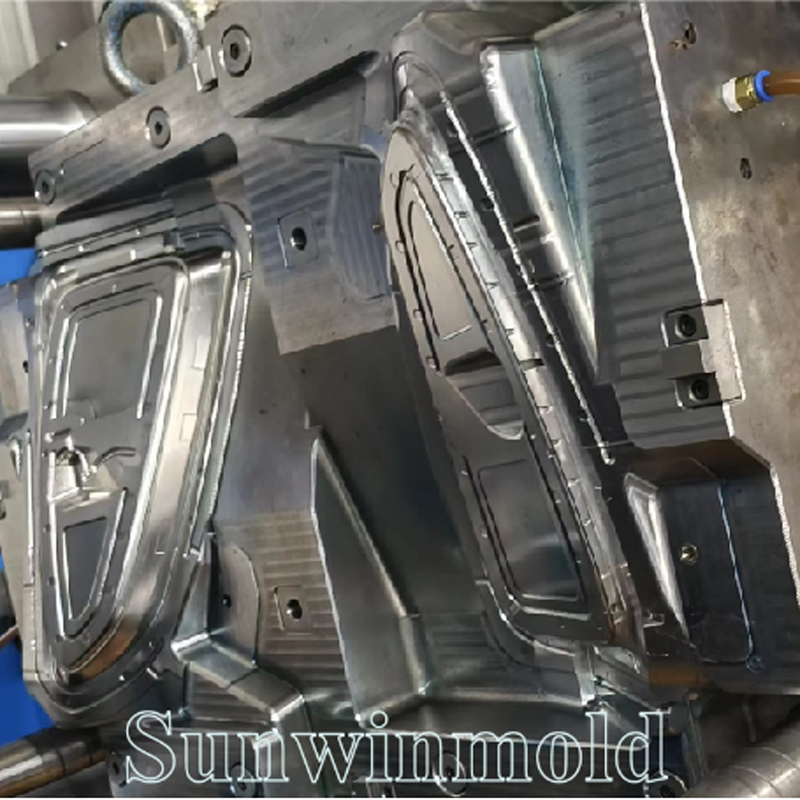

{Company Name} is a leading provider of precision plastic molding solutions, offering a full range of services from design and engineering to tooling and production. With state-of-the-art facilities and a team of experienced professionals, the company has established a reputation for delivering innovative and high-quality plastic components to its customers.

The company's success can be attributed to its commitment to quality, precision, and customer satisfaction. By leveraging the latest advancements in plastic molding technology, {Company Name} is able to produce intricate and complex parts with unmatched efficiency and accuracy. This has allowed the company to meet the unique needs of its clients, whether they require small-batch prototypes or large-scale production runs.

In addition to its cutting-edge technology, {Company Name} also focuses on continuous improvement and innovation. The company is constantly investing in research and development to stay ahead of industry trends and to offer its customers the most advanced and cost-effective plastic molding solutions. By staying at the forefront of technology and embracing new techniques and materials, {Company Name} remains a trusted partner for companies looking to bring their plastic component ideas to life.

Furthermore, {Company Name} understands the importance of environmental sustainability in today's manufacturing industry. As such, the company has adopted eco-friendly practices and materials to minimize its impact on the environment. By utilizing recyclable materials and employing energy-efficient processes, {Company Name} is able to provide sustainable and environmentally responsible plastic molding solutions to its clients.

The company's dedication to quality and customer satisfaction has earned it a loyal and diverse customer base. From automotive companies to medical device manufacturers, {Company Name} has been able to serve a wide range of industries with its precision plastic molding expertise. Its track record of delivering on-time, high-quality products has made it a preferred partner for businesses seeking reliable and innovative plastic molding solutions.

Looking to the future, {Company Name} remains committed to pushing the boundaries of plastic molding technology and exploring new opportunities for growth and expansion. By staying true to its core values of quality, precision, and customer satisfaction, the company is well-positioned to continue its success and to lead the way in the fast-paced world of precision plastic molding.

In conclusion, {Company Name} is a trusted and innovative provider of precision plastic molding solutions. With its state-of-the-art facilities, commitment to quality, and focus on innovation, the company has established itself as a leading player in the industry. Its dedication to environmental sustainability and customer satisfaction further solidifies its position as a preferred partner for businesses looking for high-quality and reliable plastic molding solutions. As the manufacturing industry continues to evolve, {Company Name} is poised to remain at the forefront of precision plastic molding, delivering cutting-edge solutions to its diverse and loyal customer base.

Company News & Blog

New technology in the Pet Preform Blowing Machine industry revolutionizes production process

Pet Preform Blowing Machine has revolutionized the way pet preforms are manufactured. This advanced machine uses the latest technology to produce high-quality pet preforms that are used in the production of PET bottles for a variety of products including water, soda, juice, and more. The machine is designed to be efficient, reliable, and easy to use, making it a valuable asset for companies in the beverage and packaging industries.The company behind this innovative machine is a leading manufacturer of packaging machinery with a commitment to providing top-quality equipment for their clients. With a strong focus on research and development, the company is constantly striving to improve their products and stay ahead of industry trends. Their dedication to excellence has earned them a reputation for delivering reliable and high-performance machinery that meets the needs of their customers.The Pet Preform Blowing Machine is a prime example of the company's commitment to innovation. It is designed to streamline the production process, reducing the time and labor required to manufacture pet preforms. The machine is capable of producing a wide range of preform sizes and shapes, allowing for greater flexibility in bottle design and production. This versatility is a major advantage for companies looking to stay competitive in the ever-evolving beverage market.In addition to its advanced technology, the Pet Preform Blowing Machine is also designed with user-friendly features that make it easy to operate and maintain. This includes an intuitive control panel and a modular design that allows for easy access to key components for maintenance and repairs. The machine is also equipped with safety features to ensure the protection of operators and prevent accidents in the workplace.The company's dedication to customer satisfaction is evident in their comprehensive customer support services. They provide training and technical assistance for customers who purchase their machinery, ensuring that operators are well-equipped to maximize the efficiency and performance of the Pet Preform Blowing Machine. Furthermore, they offer prompt and reliable after-sales service, including spare parts and maintenance services to keep their machines running smoothly for years to come.As sustainability becomes an increasingly important factor in the packaging industry, the Pet Preform Blowing Machine is also designed with energy efficiency in mind. It is engineered to minimize energy consumption without sacrificing production output, making it an environmentally responsible choice for companies seeking to reduce their carbon footprint.Overall, the Pet Preform Blowing Machine is a valuable asset for companies in the beverage and packaging industries. Its advanced technology, user-friendly features, and commitment to sustainability make it a reliable and efficient solution for the production of high-quality pet preforms. With the backing of a reputable and customer-focused company, this machine is set to make a significant impact on the industry and help companies stay ahead of the competition.

Top Industrial Moulds: A Guide to Choosing the Best Moulds for Your Needs

Industrial Moulds, a leading provider of precision mould design and manufacturing solutions, has recently announced the launch of their latest line of innovative moulds. With over [number] years of experience in the industry, Industrial Moulds has established itself as a trusted and reliable partner for companies seeking high-quality mould solutions for their manufacturing processes.Established in [year], Industrial Moulds has built a strong reputation for delivering top-notch products and exceptional customer service. The company has continually invested in state-of-the-art technology and equipment to ensure that they stay ahead of the curve in the rapidly evolving mould manufacturing industry.The latest line of moulds from Industrial Moulds is designed to meet the needs of a wide range of industries, including automotive, medical, consumer goods, and more. These moulds are precision-engineered to deliver consistently high-quality and precise output, helping businesses streamline their production processes and improve overall efficiency.One of the key highlights of the new mould line is its innovative design features, which have been optimized for maximum durability and longevity. This ensures that the moulds can withstand the rigors of heavy-duty industrial use, delivering reliable performance over an extended lifespan. In addition, the moulds are also designed for ease of maintenance, helping companies minimize downtime and reduce overall operating costs.Industrial Moulds has also placed a strong emphasis on customization, offering tailored solutions to meet the unique requirements of their clients. Whether it's a complex mould design or specific material specifications, the company's team of experts works closely with customers to develop custom moulds that perfectly align with their production needs.In addition to their commitment to quality and innovation, Industrial Moulds also prioritizes sustainability in their manufacturing processes. The company has implemented stringent environmental standards and practices to minimize their carbon footprint and reduce waste generation. This commitment to sustainability resonates with many of their clients, who are increasingly prioritizing eco-friendly and responsible suppliers.Furthermore, Industrial Moulds places a significant emphasis on customer satisfaction, ensuring that every client receives personalized attention and support throughout their partnership. The company's customer service team is readily available to address any inquiries or technical support needs, fostering strong and enduring relationships with their clients.To further elevate their service offerings, Industrial Moulds has expanded their global reach, establishing strategic partnerships and distribution networks in key markets around the world. This allows the company to efficiently serve a diverse customer base and provide timely support to clients across different regions.In summary, Industrial Moulds continues to demonstrate its commitment to excellence and innovation with the launch of its latest line of moulds. The company's unwavering dedication to quality, customization, sustainability, and customer satisfaction sets them apart as a leader in the mould manufacturing industry. With a strong track record of delivering exceptional results, Industrial Moulds is well-positioned to meet the evolving needs of manufacturers and contribute to the success of their clients.

High Quality Armless Chair Mold for Sale

Armless Chair Mould, a leading manufacturer of high-quality moulds for armless chairs, is proud to announce the launch of their latest product line. With a focus on innovation and precision engineering, Armless Chair Mould has become a trusted name in the industry, providing top-notch moulds to furniture manufacturers all over the world.Established in {}, Armless Chair Mould has always been committed to delivering the best products and services to their customers. With state-of-the-art facilities and a team of experienced professionals, the company has continuously pushed the boundaries of mould manufacturing, setting new standards in the industry.The new product line from Armless Chair Mould is a testament to their dedication to excellence. The moulds are designed to meet the highest standards of quality and performance, ensuring that furniture manufacturers can produce armless chairs that are not only aesthetically pleasing but also durable and long-lasting.One of the key features of the new product line is the use of advanced materials and cutting-edge technology. Armless Chair Mould has invested heavily in research and development, constantly seeking out innovative solutions to improve their products. This has led to the creation of moulds that are highly efficient and capable of producing armless chairs with intricate designs and complex shapes.In addition to technological advancements, Armless Chair Mould also takes pride in their commitment to sustainability. The company places a strong emphasis on environmental responsibility, using eco-friendly materials and processes in their manufacturing operations. This not only benefits the environment but also allows furniture manufacturers to align with the growing demand for sustainable products in the market.Furthermore, Armless Chair Mould understands the challenges faced by furniture manufacturers in today's competitive market. As such, they have designed their new product line to offer greater flexibility and customization options. Whether it's a specific design requirement or a unique production need, the moulds from Armless Chair Mould can be tailored to meet the exact specifications of their customers.To support their new product line, Armless Chair Mould has also enhanced their customer service and support capabilities. The company is dedicated to providing comprehensive assistance to their clients, from the initial consultation and design phase to after-sales support. This ensures that furniture manufacturers can rely on Armless Chair Mould as a trusted partner for their mould needs.With the launch of their new product line, Armless Chair Mould aims to further solidify their position as a leading provider of moulds for armless chairs. The company's unwavering commitment to quality, innovation, and customer satisfaction sets them apart in the industry, earning the trust and loyalty of their clients.As the demand for high-quality armless chairs continues to grow, Armless Chair Mould remains at the forefront of mould manufacturing, driving progress and setting new benchmarks for excellence. With their latest product line, the company looks forward to empowering furniture manufacturers with the tools they need to create exceptional armless chairs that stand out in the market.

Injection Molding: How It Works and Its Benefits

Iml Injection Molding, a leading manufacturer in the plastic injection molding industry, has recently made significant advancements in their technology, positioning themselves as a key player in the industry. Founded in 1995, the company has grown to become a well-established manufacturer of high-quality plastic products. Their state-of-the-art facilities and experienced team have enabled them to provide top-notch solutions to their clients, both locally and internationally.Iml Injection Molding has always been at the forefront of innovation and has continuously invested in the latest technologies to enhance their manufacturing processes. Their recent advancement in injection molding technology has further solidified their position as an industry leader.The company's innovative IML (In-Mold Labeling) technology allows for the incorporation of complex and detailed designs directly into the molded plastic products. This process involves the placement of a pre-printed label into the mold, where it fuses with the molten plastic, resulting in a seamless and durable finish. This technology has revolutionized the way in which branding and labeling are integrated into plastic products. With IML, the labels are an integral part of the product, eliminating the need for additional labeling processes and ensuring a high level of durability and resistance to wear and tear.In addition to providing superior aesthetic appeal, Iml Injection Molding's IML technology offers a range of functional benefits. The labels are highly resistant to moisture, chemicals, and scratches, making them ideal for a wide range of applications, including food packaging, household products, and automotive components. Furthermore, the in-mold labeling process allows for faster production cycles and reduced labor costs, resulting in a more efficient and cost-effective manufacturing solution."We are thrilled to introduce our advanced IML technology to the market," says the CEO of Iml Injection Molding. "This innovation represents a significant milestone for our company and for the plastic injection molding industry as a whole. We believe that our IML technology will set a new standard for product labeling and branding, providing our clients with unparalleled design possibilities and functional advantages."The company's commitment to innovation and excellence has garnered them a strong reputation in the industry. Their IML technology has already received positive feedback from clients and has been met with enthusiasm from various sectors, including the food and beverage, consumer goods, and automotive industries. With this latest advancement, Iml Injection Molding has enhanced their capabilities and strengthened their position as a preferred partner for high-quality plastic products.In conclusion, Iml Injection Molding's IML technology represents a significant leap forward for the plastic injection molding industry. The company's dedication to innovation and their commitment to providing top-quality solutions have positioned them as a leader in the industry. With their advanced IML technology, Iml Injection Molding is well-equipped to meet the diverse needs of their clients and to continue driving advancements in the plastic manufacturing sector.

A Guide to Pet Molding Machines: What You Need to Know

Pet Molding Machine Revolutionizes Production Process for Pet ProductsIn today's fast-paced world, the demand for pet products continues to grow at an unprecedented rate. From pet food to accessories, the pet industry is one of the most thriving sectors in the consumer market. As a result, manufacturers are constantly looking for innovative ways to streamline their production processes in order to meet the ever-increasing demand. This is where the revolutionary Pet Molding Machine comes into play.Company Introduction: A leading technology company in the pet industry, specializing in the development and production of high-quality pet products. With a strong focus on innovation and sustainability, the company has established itself as a trusted partner for pet product manufacturers worldwide.The Pet Molding Machine, developed and manufactured by the company, is a state-of-the-art system designed to revolutionize the production process for pet products. This cutting-edge machine is equipped with advanced technology that allows for the efficient and precise molding of a wide range of pet-related items, including food and water bowls, toys, litter boxes, and more.One of the key features of the Pet Molding Machine is its ability to produce high-quality pet products at a rapid pace. With its advanced mold design and automated production system, the machine significantly reduces production time, allowing manufacturers to meet the growing demand for pet products in a timely manner.Furthermore, the Pet Molding Machine is designed to be versatile and adaptable to a variety of production needs. Whether it's a small batch of custom-designed pet products or a large-scale production run, the machine is capable of accommodating different specifications and requirements, providing manufacturers with the flexibility they need to stay ahead in the competitive pet industry.Aside from its efficiency and versatility, the Pet Molding Machine is also hailed for its sustainability and cost-effectiveness. By optimizing the use of raw materials and energy, the machine minimizes waste and reduces production costs, making it a viable solution for manufacturers looking to improve their bottom line while minimizing their environmental impact.Moreover, the company behind the Pet Molding Machine is committed to providing comprehensive support and technical assistance to its clients. From installation and training to maintenance and troubleshooting, the company's team of experts is readily available to ensure that the machine operates at its optimal performance, allowing manufacturers to maximize their production capabilities and achieve superior product quality.The impact of the Pet Molding Machine on the pet industry has been nothing short of transformative. By streamlining the production process for pet products, the machine has enabled manufacturers to keep up with the increasing demand while maintaining high standards of quality and efficiency. As a result, pet owners around the world can expect a wider variety of innovative and high-quality products to choose from, catering to the diverse needs and preferences of their beloved pets.In conclusion, the Pet Molding Machine represents a game-changing innovation in the pet industry, providing manufacturers with the tools they need to stay competitive in a fast-growing market. With its advanced technology, efficiency, sustainability, and versatility, the machine has set a new standard for pet product production, revolutionizing the way pet products are made and ultimately enhancing the lives of pets and pet owners everywhere.

High-Quality ABS Pellets for Injection Molding: Everything You Need to Know

Abs Pellets For Injection Molding Combined With The Company IntroductionThe market for injection molding is growing rapidly, and the demand for high-quality ABS pellets is higher than ever before. With the increasing need for durable and versatile plastics for a wide range of industries, companies are constantly on the lookout for reliable suppliers of ABS pellets for injection molding. This is where [Company Name] comes in, offering top-quality ABS pellets that meet the strictest industry standards.[Company Name] is a leading supplier of ABS pellets for injection molding, with a reputation for delivering excellent quality products to customers around the world. The company has been in the business for over [number] years, and has a deep understanding of the unique requirements of the injection molding industry. This expertise allows the company to provide its customers with tailored solutions that meet their specific needs.The ABS pellets offered by [Company Name] are highly versatile, making them suitable for a wide range of applications. Whether it's for automotive parts, electronic components, or consumer goods, these pellets are designed to deliver outstanding performance and durability. The company's ABS pellets are also available in a variety of grades and colors, allowing customers to choose the perfect material for their specific injection molding needs.One of the key factors that sets [Company Name] apart from its competitors is its commitment to quality. The company has strict quality control measures in place throughout the production process, ensuring that its ABS pellets consistently meet the highest standards. From raw material sourcing to the final packaging and delivery, every step is carefully monitored to guarantee the quality and consistency of the products.In addition to its dedication to quality, [Company Name] also prides itself on its excellent customer service. The company works closely with its customers to understand their individual requirements and provide them with the best possible solutions. This customer-centric approach has earned [Company Name] a solid reputation in the industry, with many long-standing relationships with satisfied clients.As the demand for ABS pellets for injection molding continues to grow, [Company Name] is well-positioned to meet the needs of its customers. The company has a strong focus on innovation and constantly seeks to improve its products and services to stay ahead of the competition. With a team of highly skilled professionals and state-of-the-art manufacturing facilities, [Company Name] is able to consistently deliver high-quality ABS pellets that meet the evolving needs of the injection molding industry.In conclusion, [Company Name] is a trusted supplier of ABS pellets for injection molding, with a strong track record of delivering exceptional products and services to its customers. With a commitment to quality, innovation, and customer satisfaction, the company is well-equipped to meet the growing demand for ABS pellets and continue to be a leader in the injection molding industry.

Revolutionizing Manufacturing: The Key Advantages of Injection Molding

Introducing Innovative Insert Injection Molding Technology: Revolutionizing Manufacturing ProcessesIn an ever-evolving world, where technology is constantly pushing the boundaries of numerous industries, insert injection molding has emerged as a game-changing manufacturing process. This groundbreaking innovation, employed by numerous companies across various sectors, allows for the production of highly intricate and detailed products with unmatched precision and efficiency.One prominent leader in the insert injection molding industry is the renowned company {}, known for its commitment to excellence and cutting-edge technology. With a vast portfolio of successful projects and a reputation for delivering top-tier solutions, {} stands at the forefront of revolutionizing manufacturing processes.Insert injection molding is a manufacturing technique that involves injecting molten material, typically a thermoplastic or thermosetting polymer, into a pre-formed mold. Nevertheless, what makes this technique unique is the incorporation of inserts during the molding process. These inserts can be metal, ceramic, or plastic parts that are placed strategically within the mold, enhancing the final product's durability and functionality.The advantages of insert injection molding cannot be overstated. First and foremost, this process allows for a high degree of design flexibility. Inserts can be precisely positioned within the mold, thereby enabling the creation of intricate components with unparalleled accuracy. This level of precision opens up new possibilities for industries such as automotive, electronics, and medical devices, where intricate and complex parts are often required.Furthermore, insert injection molding drastically reduces manufacturing time and costs. By incorporating inserts during the molding process, manufacturers can eliminate the need for secondary operations such as drilling, fastening, or welding. This streamlining of production eliminates additional labor costs and significantly reduces assembly time, resulting in a more efficient and cost-effective manufacturing process.Moreover, insert injection molding offers enhanced product quality and durability. The integration of inserts improves the structural integrity of the final product, making it stronger and more resistant to external factors such as temperature fluctuations, pressure, or mechanical stress. Consequently, products manufactured through this process boast increased reliability and longevity, meeting the stringent demands of various industries.With a vision to revolutionize manufacturing processes, {} has perfected their insert injection molding techniques by combining innovative technology, engineering expertise, and meticulous quality control. {} has established itself as a trusted partner for numerous industry leaders, delivering exceptional solutions tailored to their specific needs.One industry that has greatly benefited from insert injection molding is the automotive sector. With an increasing demand for lightweight and durable components, this technology allows automotive manufacturers to produce intricate and complex parts that were once deemed challenging. From interior trims to electronic housings, insert injection molding has become the go-to solution for achieving high precision and outstanding performance in the automotive industry.Similarly, the electronics industry has witnessed the transformative power of insert injection molding. With the growing trend of miniaturization, electronics manufacturers constantly seek ways to pack more functionality in smaller devices. Insert injection molding enables the production of intricate electronic components with reduced form factors, without compromising their structural integrity or performance. This technology has facilitated the development of innovative electronic devices, offering users a level of convenience and functionality never seen before.Lastly, the medical device industry has embraced insert injection molding for manufacturing critical components such as catheters, implants, or surgical instruments. These devices require exceptional precision, biocompatibility, and strength, all of which are made possible through insert injection molding. This technology ensures that medical devices meet the rigorous quality and safety standards, while also allowing for cost-effective solutions in an industry where every second matters.In conclusion, insert injection molding has emerged as a game-changing technology in the manufacturing industry. With innovation at its core, {} has been instrumental in advancing this technique, revolutionizing numerous industries along the way. The diverse advantages of insert injection molding, including design flexibility, reduced costs, enhanced product quality, and durability, make it an indispensable manufacturing solution. As technology continues to evolve, we can only anticipate further advancements in this field, resulting in even more efficient and groundbreaking manufacturing processes.

Advanced Injection Molding Technology for Eva Material - Discover the Latest Innovations

Eva Injection Molding is a specialized manufacturing process that uses ethylene vinyl acetate (EVA) to produce a wide range of products. This innovative method has gained popularity in various industries due to its flexibility, durability, and cost-effectiveness. With the growing demand for EVA injection molding solutions, many companies are eager to capitalize on this trend and enhance their manufacturing capabilities.One such company that has embraced the potential of Eva Injection Molding is {Company Name}. With over two decades of experience in the injection molding industry, {Company Name} has established itself as a leading provider of high-quality plastic components and products. The company is known for its cutting-edge technology, state-of-the-art facilities, and expertise in delivering custom solutions for diverse applications.{Company Name}'s decision to integrate Eva Injection Molding into its manufacturing processes is a testament to its commitment to staying ahead of industry trends and meeting the evolving needs of its clients. By leveraging the benefits of EVA, {Company Name} aims to expand its product offerings, improve production efficiency, and deliver enhanced performance and durability in its plastic components.One of the key advantages of Eva Injection Molding is its ability to produce products with excellent cushioning and shock absorption properties. This makes it an ideal choice for manufacturing footwear, orthotic insoles, and sports equipment. Additionally, EVA's lightweight and flexible nature make it suitable for applications in the automotive, electronics, and healthcare industries.{Company Name} recognizes the immense potential of EVA injection molding in catering to the diverse needs of its customers. By incorporating this advanced technology into its operations, the company is poised to offer a wider range of products with enhanced performance and durability. This strategic move aligns with {Company Name}'s dedication to delivering innovative solutions and maintaining a competitive edge in the injection molding market.Furthermore, {Company Name}'s investment in Eva Injection Molding reflects its commitment to sustainability and environmental responsibility. EVA is a thermoplastic material that is 100% recyclable, making it a more eco-friendly option compared to other plastics. By embracing this eco-conscious approach, {Company Name} aims to reduce its environmental footprint and contribute to a greener, more sustainable future.The integration of Eva Injection Molding into {Company Name}'s manufacturing processes is a testament to the company's forward-thinking mindset and dedication to delivering exceptional quality to its customers. With its extensive experience and expertise in injection molding, {Company Name} is well-positioned to harness the full potential of EVA and provide innovative, high-performance products across various industries.In conclusion, the incorporation of Eva Injection Molding into {Company Name}'s operations marks a significant milestone in the company's evolution. By embracing this advanced technology, {Company Name} is poised to expand its product offerings, enhance production efficiency, and meet the evolving demands of its clients. With a focus on sustainability and innovation, {Company Name} is set to solidify its position as a leader in the injection molding industry and continue delivering superior quality products to its customers.

Discover Precision Injection Molding Techniques for High-Quality Plastic Parts

Title: Advancements in Plastic Molding Propels Manufacturing Industry ForwardIntroduction:The field of plastic molding has witnessed remarkable advancements over the years, resulting in a significant transformation of the manufacturing industry. One prominent player in this sector, referred to as "Prototype Plastic Molding" in this article, has emerged as a pioneer in delivering cutting-edge plastic molding solutions. Throughout this news article, we will explore the ongoing developments in plastic molding technology and delve into the capabilities of this leading company.1. The Evolution of Plastic Molding:The integration of advanced technologies has revolutionized the plastic molding industry, enhancing its efficiency, precision, and overall productivity. Traditional molding methods have been replaced by innovative techniques, with a strong focus on automation and computer-controlled processes. As a result, manufacturers are now able to produce complex and intricate plastic components with unmatched accuracy.2. Introduction to Prototype Plastic Molding:Prototype Plastic Molding, a globally recognized company, has been at the forefront of transforming the plastic molding landscape. With a strong emphasis on research and development, the company has consistently pushed the boundaries of manufacturing capabilities. They specialize in providing high-quality plastic parts to various industries such as automotive, electronics, medical, and consumer goods.3. Advanced Technologies:Prototype Plastic Molding has successfully adopted and integrated several advanced technologies within its manufacturing processes. The company utilizes computer-aided design (CAD) software to create precise digital models of the desired plastic components. These models are then translated into instructions for computer numerical control (CNC) machines, which enable the production of molds with extreme precision. Moreover, the company incorporates state-of-the-art 3D printing technologies to create prototypes before mass production, thereby ensuring the seamless development of new products.4. Enhanced Prototyping Capabilities:Through the utilization of their advanced CAD software and 3D printing technologies, Prototype Plastic Molding has elevated its prototyping capabilities. This enables their clients to visualize and assess the functionality, aesthetics, and ergonomics of their plastic components before final production begins. By streamlining the prototyping phase, the company diminishes the time and costs associated with product development, creating a competitive advantage for their clients.5. Emphasis on Sustainability:Prototype Plastic Molding maintains a strong commitment to sustainability, actively exploring ways to minimize waste and lower their environmental impact. The company utilizes recycled materials whenever possible, while also developing innovative solutions to optimize material usage. By implementing sustainable practices and adhering to stringent quality control measures, they ensure eco-friendly production while simultaneously meeting the evolving demands of the market.6. Cutting-edge Equipment and Expertise:Prototype Plastic Molding continuously invests in cutting-edge machinery and equipment to enhance their manufacturing capabilities. With a team of experienced professionals, they oversee every step of the production process, adhering to strict quality control standards. This holistic approach guarantees the delivery of excellent results while maintaining a rapid turnaround time for their customers.Conclusion:The advancements in plastic molding technology, spearheaded by companies like Prototype Plastic Molding, are revolutionizing the manufacturing sector. With their innovative techniques, commitment to sustainability, and expertise in delivering high-quality plastic components, Prototype Plastic Molding has earned a commendable reputation in the industry. As the manufacturing industry continues to evolve, plastic molding is expected to play an increasingly significant role, shaping the future of numerous sectors.

Essential Tips for Designing a Preform Mould

Preform Mould, a leading manufacturer of high-quality preform molds, is making waves in the industry with its innovative and reliable products. With a focus on precision engineering and cutting-edge technology, the company has become a trusted name in the plastics industry.Preform Mould has a proven track record of delivering top-notch preform molds that meet the highest standards of quality and performance. The company's state-of-the-art manufacturing facility is equipped with advanced machinery and tools, allowing for the production of molds that are precise, durable, and consistent in their performance.One of the key factors that sets Preform Mould apart from its competitors is its commitment to continuous innovation. The company invests heavily in research and development, constantly pushing the boundaries of mold design and manufacturing techniques. As a result, Preform Mould is able to offer its customers cutting-edge solutions that are at the forefront of industry standards.In addition to its focus on innovation, Preform Mould places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific needs and requirements, and tailors its products to meet those needs. From custom mold designs to after-sales support, Preform Mould goes above and beyond to ensure that its customers are fully satisfied with their purchases.Preform Mould's dedication to quality and customer satisfaction has earned it a loyal and growing customer base. The company serves a wide range of industries, including beverage, food, pharmaceutical, and cosmetic packaging. Its molds are used to produce a variety of plastic products, including bottles, jars, and containers, among others.Moreover, Preform Mould has a strong commitment to sustainability and environmental responsibility. The company strives to minimize its environmental impact through the use of eco-friendly materials and manufacturing processes. By providing durable and long-lasting molds, Preform Mould helps its clients reduce their carbon footprint and contribute to a more sustainable future.In line with its commitment to excellence, Preform Mould has achieved various certifications and accolades that attest to the quality of its products and services. The company's ISO certification and other industry recognitions serve as a testament to its dedication to upholding the highest standards of production and customer satisfaction.Looking ahead, Preform Mould is poised to further expand its presence in the global market. The company is actively exploring new opportunities for growth and development, with a focus on expanding its product range and reaching new customers. With its proven track record of success and a strong foundation built on quality and innovation, Preform Mould is well-positioned to continue setting new benchmarks in the preform mold industry.In conclusion, Preform Mould is a company that stands out for its commitment to excellence, innovation, and customer satisfaction. With a focus on precision engineering, advanced technology, and sustainable practices, the company has established itself as a leader in the industry. As it continues to grow and evolve, Preform Mould is set to further solidify its position as a trusted partner for businesses in need of high-quality preform molds.