Maximizing Production with High Volume Injection Molding

By:Admin

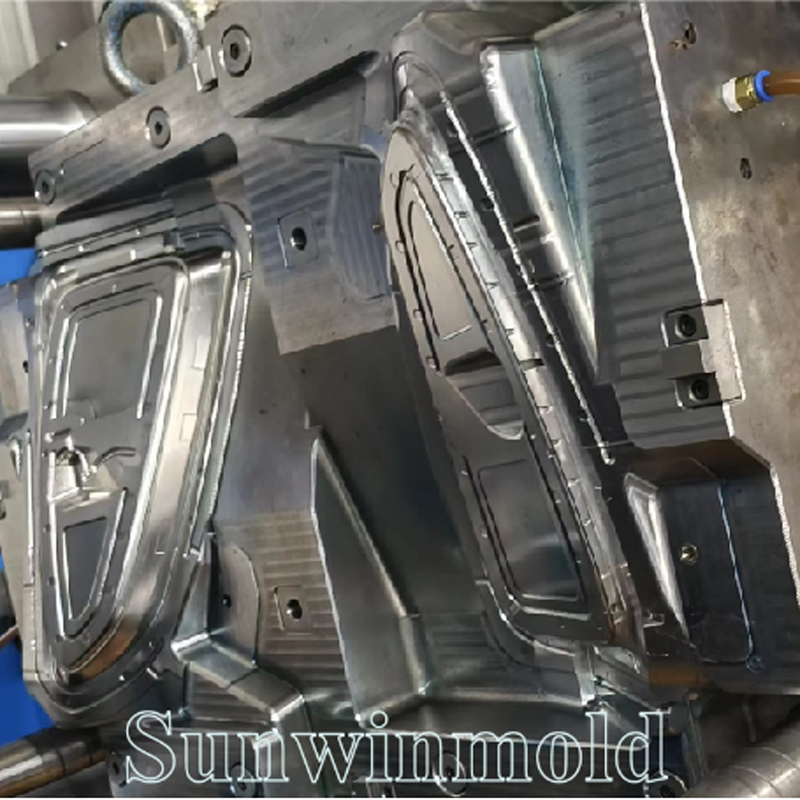

In the world of manufacturing, high volume injection molding technology has revolutionized the way products are designed, produced, and distributed. This cutting-edge technology allows companies to rapidly develop and produce large quantities of plastic parts with exceptional precision and consistency. With the ability to produce intricate and complex shapes at a rapid pace, high volume injection molding has become an integral part of the manufacturing industry.

One company that has been at the forefront of high volume injection molding technology is {}. Founded in {}, the company has built a reputation for delivering high-quality plastic injection molding solutions for a wide range of industries, including automotive, consumer electronics, medical, and more. With state-of-the-art facilities and a team of experienced engineers and technicians, {} has positioned itself as a leader in the field of high volume injection molding.

The key to the success of {} lies in its advanced manufacturing capabilities. The company's production facilities are equipped with the latest injection molding machines, capable of producing large volumes of plastic parts with incredible speed and precision. These machines are operated by highly skilled technicians who are trained to optimize production processes and ensure the highest quality standards are met.

Furthermore, {} has invested heavily in research and development to continuously improve its injection molding technology. By leveraging the latest innovations in materials, design software, and automation, the company has been able to push the boundaries of what is possible with high volume injection molding. This commitment to innovation has allowed {} to stay ahead of the curve and deliver cutting-edge solutions to its clients.

The advantages of high volume injection molding are numerous. Firstly, it allows for the cost-effective production of large quantities of plastic parts, making it an ideal solution for mass production. Additionally, the technology is highly versatile, capable of producing parts in a wide range of shapes, sizes, and complexities. This versatility enables manufacturers to create custom-designed components that meet their specific needs.

Moreover, high volume injection molding offers exceptional repeatability and consistency. With tight tolerances and minimal variation, manufacturers can rely on the technology to produce parts that are identical in quality and performance. This level of consistency is crucial for applications where precision is paramount, such as in the medical and aerospace industries.

With the rise of additive manufacturing and 3D printing, some may question the relevance of high volume injection molding. However, the technology continues to be indispensable for many industries. While 3D printing excels in producing prototypes and low-volume runs, high volume injection molding is unmatched in its ability to produce large quantities of parts with exceptional speed and efficiency.

Looking ahead, the future of high volume injection molding looks promising. As technology continues to evolve, we can expect to see further advancements in materials, process automation, and digital integration. These developments will further enhance the capabilities of high volume injection molding, making it an even more attractive option for manufacturers seeking cost-effective and high-quality production solutions.

In conclusion, high volume injection molding technology has had a profound impact on the manufacturing industry, enabling companies to produce large quantities of plastic parts with exceptional precision and speed. {}. With its advanced manufacturing capabilities and commitment to innovation, the company has established itself as a leader in the field of high volume injection molding. As technology continues to advance, we can only expect to see further growth and innovation in this space, cementing high volume injection molding's place as a cornerstone of modern manufacturing.

Company News & Blog

Top Quality Perfume Mold Supplier from China

China Perfume Mold Supplier, one of the leading manufacturers of perfume molds and packaging solutions, has been making waves in the industry with its innovative products and impeccable customer service. With a focus on quality and precision, the company has quickly become a trusted partner for numerous perfume brands around the world.Founded in 2005, China Perfume Mold Supplier has established itself as a key player in the perfume packaging industry. The company's state-of-the-art manufacturing facility and skilled workforce have allowed it to produce a wide range of high-quality molds and packaging solutions for its clients. From custom-designed molds to standard packaging options, the company is able to meet the diverse needs of its customers with ease.One of the key factors that sets China Perfume Mold Supplier apart from its competitors is its commitment to innovation. The company invests heavily in research and development, constantly seeking new ways to improve its products and processes. This dedication to innovation has led to the development of several groundbreaking products that have helped the company stand out in the market.In addition to its focus on innovation, China Perfume Mold Supplier is also known for its uncompromising stance on quality. The company follows strict quality control measures at every stage of the manufacturing process to ensure that its products meet the highest standards. This attention to detail has earned the company a reputation for reliability and excellence among its clientele.Furthermore, China Perfume Mold Supplier places a strong emphasis on customer service. The company's team of dedicated professionals works closely with each client to understand their specific needs and provide tailored solutions. Whether it's collaborating on a custom mold design or delivering a large order on a tight deadline, the company goes above and beyond to ensure customer satisfaction.Riding on its success in the domestic market, China Perfume Mold Supplier has been steadily expanding its reach to international markets. The company's commitment to quality and innovation has resonated with clients worldwide, leading to partnerships with leading perfume brands in Europe, the United States, and other regions. This global expansion has further solidified the company's position as a trusted supplier in the industry.Looking ahead, China Perfume Mold Supplier is poised for continued growth and success. The company remains dedicated to pushing the boundaries of innovation and quality, as well as expanding its global presence. With its proven track record and unwavering commitment to customer satisfaction, China Perfume Mold Supplier is set to remain a driving force in the perfume packaging industry for years to come.In conclusion, China Perfume Mold Supplier has established itself as a reliable and innovative supplier of perfume molds and packaging solutions. With a focus on quality, innovation, and customer service, the company has garnered a strong reputation in the industry and continues to expand its reach in international markets. With a steadfast commitment to excellence, China Perfume Mold Supplier is well-positioned for sustained success in the years ahead.

Durable Metal Molds for Plastic Manufacturing: A Cost-Effective Solution

Metal Molds For PlasticMetal molds for plastics are essential tools in the manufacturing industry, playing a crucial role in the production of various plastic products. These molds are used to shape and produce plastic parts and products through the process of injection molding. The quality and precision of these molds are paramount to the production of high-quality plastic products.One company that has been at the forefront of producing high-quality metal molds for plastics is {}. With years of experience and expertise in the field, they have established themselves as a trusted and reliable supplier of metal molds for plastic to various industries.Established in {}, {} has been a leading manufacturer of metal molds for plastic, serving a wide range of industries including automotive, electronics, consumer goods, and more. Their state-of-the-art facilities and advanced manufacturing capabilities allow them to produce metal molds with exceptional precision and quality.The company specializes in the design and production of custom metal molds for plastic, catering to the specific needs and requirements of their clients. Whether it is complex geometric shapes, intricate designs, or tight tolerances, {} has the expertise and technology to deliver molds that meet the highest standards.Their team of highly skilled engineers and technicians work closely with clients to understand their unique requirements and provide custom mold solutions that are tailored to their specific applications. From the initial design and engineering phase to the final production and delivery, {} ensures that every step of the process is carried out with the utmost attention to detail and quality.In addition to custom mold manufacturing, {} also offers mold repair and maintenance services to ensure the longevity and performance of their molds. Their comprehensive approach to mold maintenance helps clients maximize the lifespan of their molds and minimize downtime in their production processes.With a commitment to innovation and continuous improvement, {} continually invests in research and development to stay at the forefront of mold manufacturing technology. This allows them to offer advanced mold solutions that incorporate the latest advancements in materials, design, and manufacturing techniques.Furthermore, {} is dedicated to upholding the highest standards of quality and safety in their manufacturing processes. Their facilities are equipped with advanced quality control systems to ensure that every mold meets the strictest quality standards before it is delivered to the client.As a result of their dedication to excellence and customer satisfaction, {} has built a strong reputation in the industry as a trusted supplier of metal molds for plastic. Their commitment to delivering high-quality, custom mold solutions has earned them the trust and loyalty of a wide range of clients from various industries.In conclusion, metal molds for plastic play a crucial role in the production of high-quality plastic products, and {} has proven to be a leader in the manufacturing of these molds. With their expertise, advanced capabilities, and commitment to quality, they continue to be a preferred partner for clients seeking custom metal molds for their plastic production needs.

Understanding the Cost of Injection Moulding Die: Factors to Consider

Injection Moulding Die Cost: A Key Factor in Manufacturing SuccessInjection moulding is a widely used manufacturing process in which melted material is injected into a mould, which then cools and solidifies to form a specific shape. This process is commonly used to produce a variety of items, including plastic components, toys, and medical devices. The cost of injection moulding dies is a key factor in the overall production cost and can significantly impact the profitability of a manufacturing operation.Choosing the right company for injection moulding die production is crucial for ensuring high-quality, cost-effective manufacturing. That's where [Company Name], a leader in the injection moulding industry, comes into play.[Company Name] is a renowned company with a long history of providing top-quality injection moulding dies for a wide range of industries. With state-of-the-art technology and a team of skilled engineers, [Company Name] has a proven track record of delivering high-performance moulds that meet the specific needs of its customers.The cost of injection moulding dies is a complex consideration that involves several factors. The initial design and manufacturing of the die, as well as overhead costs and material expenses, all play a role in determining the overall cost. Factors such as die complexity, material type, and production volume can all impact the final cost of the mould.When it comes to choosing a company for injection moulding die production, it's crucial to consider not only the cost but also the quality and reliability of the products. [Company Name] prides itself on offering competitive pricing without compromising on the quality of its moulds. By leveraging its extensive experience and technical expertise, [Company Name] is able to deliver cost-effective solutions that meet the highest industry standards.In addition to providing high-quality injection moulding dies, [Company Name] also offers a range of services to support its customers throughout the manufacturing process. From initial design and prototyping to production and post-sale support, [Company Name] is dedicated to helping its customers achieve success in their manufacturing operations.The choice of company for injection moulding die production can have a significant impact on the overall efficiency and profitability of a manufacturing operation. By partnering with a reliable and experienced company like [Company Name], manufacturers can benefit from cost-effective solutions that meet their specific needs and deliver superior performance.In conclusion, the cost of injection moulding dies is a crucial consideration for manufacturers looking to optimize their production processes. Choosing the right company for die production is essential for ensuring high-quality, cost-effective manufacturing. With its proven track record, technical expertise, and commitment to customer satisfaction, [Company Name] is well-positioned to meet the diverse needs of its customers and contribute to their success in the injection moulding industry.

Essential Tips for Designing a Preform Mould

Preform Mould, a leading manufacturer of high-quality preform molds, is making waves in the industry with its innovative and reliable products. With a focus on precision engineering and cutting-edge technology, the company has become a trusted name in the plastics industry.Preform Mould has a proven track record of delivering top-notch preform molds that meet the highest standards of quality and performance. The company's state-of-the-art manufacturing facility is equipped with advanced machinery and tools, allowing for the production of molds that are precise, durable, and consistent in their performance.One of the key factors that sets Preform Mould apart from its competitors is its commitment to continuous innovation. The company invests heavily in research and development, constantly pushing the boundaries of mold design and manufacturing techniques. As a result, Preform Mould is able to offer its customers cutting-edge solutions that are at the forefront of industry standards.In addition to its focus on innovation, Preform Mould places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific needs and requirements, and tailors its products to meet those needs. From custom mold designs to after-sales support, Preform Mould goes above and beyond to ensure that its customers are fully satisfied with their purchases.Preform Mould's dedication to quality and customer satisfaction has earned it a loyal and growing customer base. The company serves a wide range of industries, including beverage, food, pharmaceutical, and cosmetic packaging. Its molds are used to produce a variety of plastic products, including bottles, jars, and containers, among others.Moreover, Preform Mould has a strong commitment to sustainability and environmental responsibility. The company strives to minimize its environmental impact through the use of eco-friendly materials and manufacturing processes. By providing durable and long-lasting molds, Preform Mould helps its clients reduce their carbon footprint and contribute to a more sustainable future.In line with its commitment to excellence, Preform Mould has achieved various certifications and accolades that attest to the quality of its products and services. The company's ISO certification and other industry recognitions serve as a testament to its dedication to upholding the highest standards of production and customer satisfaction.Looking ahead, Preform Mould is poised to further expand its presence in the global market. The company is actively exploring new opportunities for growth and development, with a focus on expanding its product range and reaching new customers. With its proven track record of success and a strong foundation built on quality and innovation, Preform Mould is well-positioned to continue setting new benchmarks in the preform mold industry.In conclusion, Preform Mould is a company that stands out for its commitment to excellence, innovation, and customer satisfaction. With a focus on precision engineering, advanced technology, and sustainable practices, the company has established itself as a leader in the industry. As it continues to grow and evolve, Preform Mould is set to further solidify its position as a trusted partner for businesses in need of high-quality preform molds.

Discover the Latest Advancements in Jumbo Bin Mould Production

[Title]Leading Manufacturer Introduces Advanced Jumbo Bin Mould, Revolutionizing Warehouse Storage Solutions[Introduction]In an era where efficiency and sustainability are paramount, the manufacturing industry continuously seeks innovative solutions that can optimize processes while minimizing costs. Addressing this need, a prominent manufacturer has recently announced the development of a cutting-edge Jumbo Bin Mould, poised to revolutionize warehouse storage solutions worldwide. This ground-breaking product promises to enhance storage capacity, streamline logistics operations, and contribute to a more sustainable future through its advanced design and unparalleled durability.[Company Introduction]With over two decades of experience in the manufacturing sector, our company has firmly established itself as an industry leader in the development and production of high-quality moulds. Committed to driving innovation and meeting the evolving needs of our customers, we have consistently delivered solutions that enable businesses to enhance productivity and improve their bottom line. Our dedicated team of engineers, technicians, and designers work tirelessly to deliver groundbreaking products that exceed customer expectations.[Product Overview]The recently introduced Jumbo Bin Mould represents a significant breakthrough in the field of warehouse storage solutions. This mold is designed to create large storage bins, which are used extensively across industries such as logistics, manufacturing, and retail to store and transport various materials. The innovative design, coupled with superior material selection, ensures these jumbo bins offer exceptional strength, durability, and longevity.[Benefits]The Jumbo Bin Mould offers numerous benefits that significantly improve warehouse storage efficiency. Firstly, it enables businesses to maximize their storage capacity by efficiently utilizing available space. With their large dimensions, these bins have a higher storage capacity compared to conventional storage solutions. This translates into optimized use of warehouse space, allowing organizations to store more goods in the same area.Furthermore, these jumbo bins are constructed to be stackable, facilitating efficient transportation and easy retrieval of goods. The strategic placement of reinforced handles and sturdy castors allows for seamless mobility, increasing productivity and reducing potential hazards. By improving the accessibility and maneuverability of stored materials, organizations can reduce handling time and enhance overall operational efficiency.Additionally, the Jumbo Bin Mould offers exceptional durability and resistance to impact, chemicals, and extreme temperatures. This ensures that the bins can withstand rigorous handling and harsh working environments without compromising their structural integrity. With their extended lifespan, these jumbo bins significantly reduce the need for frequent replacements, positively impacting both cost-effectiveness and environmental sustainability.[Environmental Impact]Sustainability has become a crucial aspect of modern manufacturing practices. In line with this commitment, our Jumbo Bin Mould utilizes eco-friendly materials that are free from harmful substances. By reducing waste and promoting recyclability, these bins promote green initiatives and contribute to a greener future. Furthermore, their extended lifespan and durability further minimize the carbon footprint associated with the production and disposal of alternative storage solutions.[Conclusion]As the demand for efficient and sustainable warehouse storage solutions continues to rise, our company's introduction of the groundbreaking Jumbo Bin Mould is set to reshape the industry. This innovative product, with its advanced design, increased storage capacity, and exceptional durability, offers organizations an unprecedented opportunity to optimize their logistics operations and streamline their supply chains. With the Jumbo Bin Mould, businesses can enhance productivity, reduce costs, and contribute towards a more sustainable future.

Mastering the Art of Bobbin Molding: A Comprehensive Guide

In recent news, Bobbin Molding, a leader in the plastic injection molding industry, has announced significant growth and expansion plans for the upcoming year. The company has a reputation for providing high-quality custom plastic parts and exceptional customer service. They have been serving a wide variety of industries such as automotive, aerospace, medical devices, and consumer goods.The company has been in the plastic injection molding industry for over 20 years and is committed to staying at the forefront of innovation and excellence. Their team of experienced engineers and technicians has participated in numerous training programs and invested in state-of-the-art equipment to keep up with the competitive industry trends.Bobbin Molding offers a wide range of services, including custom design, mold tool-making, and plastic injection molding. In addition, they have an in-house tool room to produce and maintain molds, ensuring consistent quality and a shorter lead time for their customers. Their engineering team uses advanced software to provide fast flow analysis, which helps identify potential issues during the design phase, before molds are created. This method ultimately saves their customers time and money during production.Over the years, Bobbin Molding has provided its customers with high-quality and consistent products that meet or exceed their expectations. They have earned a reputation for being reliable and timely, and their exceptional customer service sets them apart from their competitors. The team at Bobbin Molding understands the importance of building relationships with their clients and have a proven track record of working collaboratively to meet their needs.In response to the growing demand for their products and services, Bobbin Molding has announced plans to expand their operations in the upcoming year. The company intends to diversify their offerings by expanding their capabilities in multi-cavity tooling and increased injection molding capacity. Moreover, they have plans to improve their production processes and invest in new technologies that will ensure the highest level of quality and reduce production time.Bobbin Molding's management team is confident that their continued investment in quality products, new technologies, and innovative production processes, will enable them to maintain their reputation as a leader in the plastic injection molding industry. The company recognizes that the customer's needs are continually evolving, and they are committed to staying ahead of the curve and meeting those needs.In conclusion, Bobbin Molding's commitment to providing high-quality products, exceptional customer service, and continuous innovation has made them a leader in the plastic injection molding industry. With their plans for expansion and investment in new technologies, the company is poised to maintain its reputation and continue providing its clients with reliable, high-quality solutions.

Durable and efficient hot runner mold for precision injection molding

Hot Runner Mold, a leader in the plastic injection molding industry, is proud to announce the launch of their latest innovative product. With over 20 years of experience in the industry, Hot Runner Mold has become a trusted name for high-quality, reliable products. The company has a strong focus on research and development, and their team of experts are constantly working to improve their products and introduce new, cutting-edge solutions to the market.The latest product from Hot Runner Mold is a hot runner system that is designed to deliver superior performance and precision in plastic injection molding. This new system offers a range of benefits, including faster cycle times, reduced waste, and improved mold quality. It is built with state-of-the-art technology and is compatible with a wide range of plastic materials, making it an ideal choice for a variety of molding applications.One of the key features of the new hot runner system is its advanced temperature control capabilities. This allows for precise control of the temperature in each individual nozzle, ensuring that the plastic material is heated and cooled at the optimal rate for excellent molding results. In addition, the system also offers improved flow control, allowing for more efficient filling of the mold cavities and reducing the likelihood of defects in the finished products.The new hot runner system from Hot Runner Mold also boasts a user-friendly design, making it easy to install and operate. It is equipped with intuitive controls and a user-friendly interface, allowing for quick and easy setup and adjustment. This design also makes it simple to maintain and service, reducing downtime and increasing productivity for plastic injection molding operations.In addition to the launch of their new hot runner system, Hot Runner Mold also offers a range of other products and services to support the plastic injection molding industry. These include a comprehensive range of hot runner components, such as nozzles, manifolds, and heaters, as well as a variety of mold maintenance and repair services. The company also provides expert technical support and consultation to help customers get the most out of their molding operations.Hot Runner Mold has built a solid reputation based on their unwavering commitment to quality, reliability, and customer satisfaction. They strive to exceed the expectations of their customers by delivering products and services that meet the highest standards of performance and durability. The company has a strong focus on fostering long-term relationships with their customers, working closely with them to understand their specific needs and provide tailored solutions that address their unique challenges.With the launch of their new hot runner system, Hot Runner Mold continues to demonstrate their leadership and innovation in the plastic injection molding industry. They are dedicated to pushing the boundaries of technology and delivering products that empower their customers to achieve new levels of excellence in their molding operations. For businesses looking to improve their molding processes and achieve superior results, Hot Runner Mold is the trusted partner for innovative solutions and unmatched expertise.

High-Quality Brass Moulding Insert for Various Applications

The brass moulding insert industry has experienced significant growth in recent years, and one company at the forefront of this trend is {company name}. {Company name} is a leading manufacturer and supplier of brass moulding inserts, serving a wide range of industries including automotive, electronics, construction, and more.With a commitment to quality, innovation, and customer satisfaction, {Company name} has established itself as a trusted partner for businesses in need of high-quality brass moulding inserts. The company's state-of-the-art manufacturing facilities and advanced technology allow them to produce a wide range of brass inserts that meet the specific needs and requirements of their customers.One of the key factors that sets {Company name} apart from its competitors is its dedication to continuous improvement and investment in research and development. This commitment has allowed {Company name} to stay ahead of the curve and provide their customers with cutting-edge brass moulding inserts that meet the highest standards of quality and performance.In addition to their focus on innovation, {Company name} also places a strong emphasis on customer service. The company has a team of knowledgeable and experienced professionals who work closely with their customers to understand their unique needs and provide them with tailored solutions. This customer-centric approach has helped {Company name} build long-lasting relationships with their clients and establish a strong reputation in the industry.Furthermore, {Company name} takes pride in its commitment to sustainability and environmental responsibility. The company implements eco-friendly practices and utilizes energy-efficient processes in their manufacturing operations, ensuring that their products are not only of the highest quality but also environmentally friendly.As a testament to their dedication to excellence, {Company name} recently introduced a new line of brass moulding inserts that offer enhanced performance and durability. These inserts are designed to withstand the most demanding applications and provide superior strength and reliability.With a strong foothold in the market, {Company name} is constantly looking for ways to expand its reach and serve more customers around the world. The company has an extensive distribution network and strategic partnerships in place to ensure that their products are readily available to businesses in various industries.Looking ahead, {Company name} is poised to continue its growth and solidify its position as a leading provider of brass moulding inserts. With a focus on technology, innovation, and customer satisfaction, the company is well-equipped to meet the ever-evolving needs of the market and drive the industry forward.In conclusion, {Company name} is a company that stands out in the competitive world of brass moulding inserts. With a relentless pursuit of excellence, a customer-centric approach, and a commitment to sustainability, {Company name} is a trusted partner for businesses seeking high-quality brass inserts. The company's dedication to innovation and continuous improvement ensures that they will remain at the forefront of the industry for years to come.

How to Clean and Prevent Mould in Flushing Cisterns

Flushing cisterns are an essential component of any modern toilet, ensuring the efficient and effective flushing of waste. However, over time, these cisterns can become susceptible to mould growth, which not only affects the appearance of the cistern but also poses potential health risks to users. In response to this issue, [removed brand name] has introduced a revolutionary new product designed to address and eliminate mould in flushing cisterns, providing a cleaner and healthier toilet environment for consumers.[Removed brand name] is a leading provider of innovative solutions for the home, with a strong focus on improving the functionality and hygiene of household fixtures. With a commitment to excellence and a dedication to addressing common issues faced by homeowners, [removed brand name] has established itself as a trusted name in the industry.The new mould removal product from [removed brand name] is a result of extensive research and development, aimed at providing a simple yet effective solution to a prevalent problem. Mould growth in flushing cisterns is often a consequence of the high moisture and humidity levels present in these environments, creating an ideal breeding ground for mould and bacteria. This can not only lead to unsightly staining and odours in the cistern but also contribute to potential health hazards for users.The innovative formula developed by [removed brand name] is specifically designed to target and eliminate mould, effectively restoring the cleanliness and hygiene of flushing cisterns. By incorporating powerful mould-fighting agents, the product can penetrate and remove existing mould growth while also preventing future occurrences. This not only improves the aesthetic appeal of the cistern but also ensures a safer and more sanitary toilet experience for consumers.In addition to its mould removal properties, the product from [removed brand name] also incorporates disinfectant and deodorizing capabilities, further enhancing its benefits for users. The multi-functional nature of the product allows for a comprehensive cleaning and maintenance solution for flushing cisterns, promoting a more hygienic and pleasant toilet environment.Furthermore, [removed brand name] has ensured that its new mould removal product is easy and convenient to use, catering to the practical needs of consumers. The application process is simple and hassle-free, requiring minimal effort for maximum results. This user-friendly approach aligns with [removed brand name]'s commitment to providing practical and accessible solutions that enhance the everyday lives of homeowners.As a company that prioritizes customer satisfaction and safety, [removed brand name] has also conducted rigorous testing and quality control measures to ensure the efficacy and reliability of its mould removal product. By adhering to high standards of performance and safety, [removed brand name] aims to instill confidence in consumers, assuring them of the product's ability to deliver exceptional results without compromising on safety.By introducing this innovative solution for mould removal in flushing cisterns, [removed brand name] seeks to address a common and persistent issue faced by homeowners, offering a reliable and effective means of maintaining the cleanliness and hygiene of their toilets. With a steadfast commitment to innovation and quality, [removed brand name] continues to demonstrate its dedication to providing practical and valuable solutions that meet the needs of consumers.In conclusion, the new mould removal product from [removed brand name] represents a significant advancement in addressing the challenge of mould growth in flushing cisterns. By leveraging its expertise and dedication to excellence, [removed brand name] has developed a solution that not only eliminates mould but also promotes a cleaner, safer, and more hygienic toilet environment for consumers. As a trusted name in the industry, [removed brand name] remains at the forefront of innovation, continuously striving to improve the everyday lives of homeowners through its innovative products and solutions.

High-Quality Perfume Mold Factories in China - Find Your Reliable Supplier Now

China Perfume Mold Factories: Leading the Way in High-Quality Perfume Packaging SolutionsChina has long been known for its excellence in manufacturing and production, and the perfume industry is no exception. With the increasing demand for high-quality perfume packaging solutions, China Perfume Mold Factories have emerged as leaders in the field, providing innovative and reliable products to companies around the world.With a strong focus on quality and customer satisfaction, China Perfume Mold Factories have garnered a reputation for excellence in the industry. They offer a wide range of perfume molds, including bottle molds, cap molds, and pump molds, all of which are designed to meet the highest standards of quality and precision. In addition to their standard line of products, they also provide custom mold design services, allowing their clients to create unique and personalized packaging solutions for their products.One of the key factors driving the success of China Perfume Mold Factories is their commitment to innovation and technology. They have invested heavily in state-of-the-art manufacturing equipment and processes, allowing them to produce molds with unparalleled accuracy and consistency. This dedication to innovation has allowed them to stay ahead of the competition and continue to meet the evolving needs of the perfume industry.Furthermore, China Perfume Mold Factories are known for their strict adherence to international quality standards. They use only the highest quality materials in their manufacturing processes, and each mold undergoes rigorous testing to ensure its durability and performance. This attention to detail has earned them the trust and loyalty of their customers, who rely on them to deliver top-notch products time and time again.Another key strength of China Perfume Mold Factories is their dedication to customer service. They understand the importance of building strong and lasting relationships with their clients, and they go above and beyond to provide exceptional support and assistance throughout the entire manufacturing process. From initial design consultations to final product delivery, they work closely with their clients to ensure that their needs are met and their expectations are exceeded.In addition to their commitment to quality and customer service, China Perfume Mold Factories also place a strong emphasis on sustainability and environmental responsibility. They have implemented eco-friendly manufacturing practices and are constantly seeking ways to reduce waste and minimize their carbon footprint. This commitment to sustainability has not only helped them reduce costs and increase efficiency but has also positioned them as leaders in the movement towards a more environmentally conscious industry.As the demand for high-quality perfume packaging solutions continues to grow, China Perfume Mold Factories are well-positioned to meet the needs of the global market. Their dedication to quality, innovation, and customer satisfaction has set them apart as leaders in the industry, and their continued success is a testament to their unwavering commitment to excellence.In conclusion, China Perfume Mold Factories have established themselves as a driving force in the perfume packaging industry, providing innovative and reliable products to companies around the world. With their focus on quality, innovation, and customer satisfaction, they have earned a reputation as leaders in the field and are well-positioned to meet the evolving needs of the global market. With their dedication to sustainability and environmental responsibility, they are not only shaping the future of perfume packaging but are also setting an example for the entire industry.