12 cavity PET preform mold

1. Imported S136 steel cavity, core, and threaded neck are used, and the heat treatment hardness can reach HRC 48-50; all formworks are heat-treated with a hardness of HRC 30-35. 2. Advanced mold design technology: Each cavity is independently self-locking, using high-precision Japanese SYATEM. To ensure the low body ratio and precision of the product. Each die has spare inserts for durable parts that are interchangeable. In order to improve and achieve high production efficiency, we always design the best cooling system, and can match a cooling machine for each mold. 3. Advanced and precise valve hot runner and temperature controller ensure the reliability of production and high light transmittance and brightness of the product. 4. The sliding mold is made of copper, the bottle body meets the food safety standard, and the life of the mold is guaranteed to be more than 3 million times.1. Mold features: 1. We specialize in the production of needle valve moulds, which do not require manual cutting. 2. The use of advanced hot runner system ensures that the AA value of the product is at a low level. 3. Reasonable cooling water channel design strengthens the cooling effect of the mold and effectively shortens the injection molding cycle.

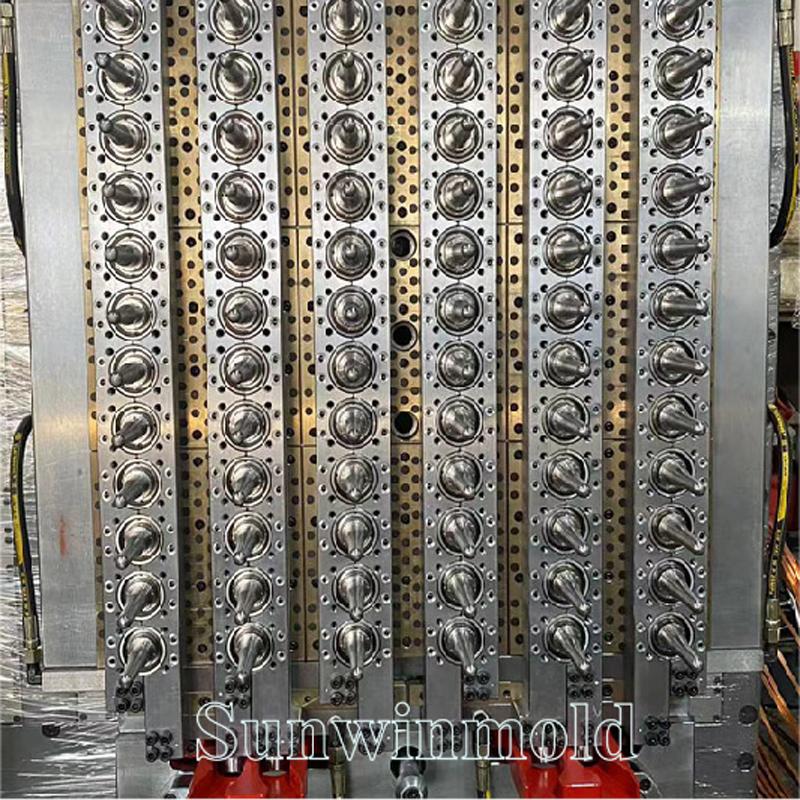

48-cavity pin valve PET preform mold

1. The hot runner adopts PID control system, which is characterized by automatic repair and automatic protection functions, which can prolong the service life of the electric heating device; -The temperature is controlled within 1°C to ensure that the raw materials are not burned in the hot runner, and the finished product rate can reach more than 99%; -The new nozzle design makes the mold easier to maintain, the thimble part of the nozzle, the heating part, the heat insulation part, and the thermocouple can be easily replaced without disassembling the mold, which is beneficial to reduce downtime and save maintenance costs. 2. Cooling system -The spiral cavity cooling water channel makes the cooling effect stronger. -The cooling water channel on the threaded port and the slider enhances the cooling effect. -Exquisitely designed central distribution plate, cooling water can be evenly introduced into each cavity, and all preforms can be effectively cooled evenly and quickly. 3. Hot runner - The hot runner with excellent balance performance ensures the flow and pressure of PET melt in all cavities are uniform. -PET melt channeling minimizes shear and IV losses and allows PET melt to flow evenly to all cavities. - Optimal heat distribution keeps the acetaldehyde (AA) content in all cavities stable. material Custom Material 632: Better than FS136 with higher nickel and chromium content. Toughness, rust resistance, and whitening effect are obviously improved. The mold base is made of HRC 38~40 stainless steel or P20 (pre-hardened). 2. Stack design of SelfLock type Before closing the mold, the parting seam is locked in place by a locking ring to minimize parting line wear on the cavity side and core side, thereby extending the burr-free life of the parting line.

24 cavity preform mold

The new preform mold structure independently researched and developed can completely eliminate most of the disadvantages of the past molds, and can achieve high-precision concentricity and long life of the mold, and can carry out standardization of various parts of the mold and mass production. Our molds ensure that the wall thickness difference of the tube blank is less than 0.05mm, and the weight error is less than 0.3g. 2-5 molds can be produced in one minute, and the service life can reach 2 million mold times. The mold has a maximum of 96 cavities.

Introduction to Mold Manufacturing

Introduction to Mold Manufacturing | Type | Height(mm) | Width(mm) | Thickness(mm) | Weight(kg) |

| 6 Cavity | 650 | 270 | 490 | 600 |

| 8 Cavity | 480 | 360 | 490 | 595 |

| 12 Cavity | 610 | 360 | 490 | 755 |

| 16 Cavity | 740 | 360 | 510 | 960 |

| 24 Cavity | 790 | 500 | 510 | 1415 |

| 32 Cavity | 800 | 580 | 510 | 1600 |

| 48 Cavity | 1120 | 600 | 560 | 2640 |

| 64 Cavity | 1380 | 600 | 610 | 3545 |

| 72 Cavity | 1170 | 800 | 610 | 4010 |

| 96 Cavity | 1230 | 960 | 610 | 5050 |