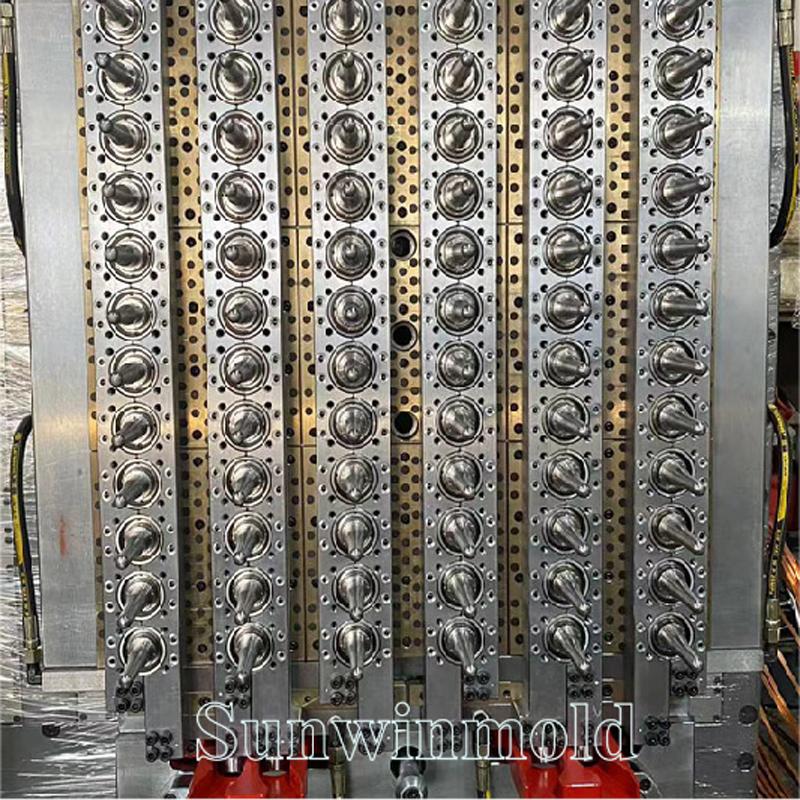

16-cavity wide mouth/wide mouth preform mold

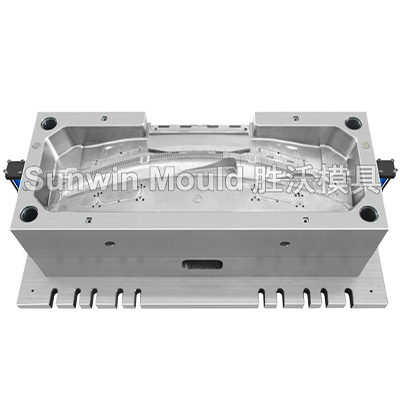

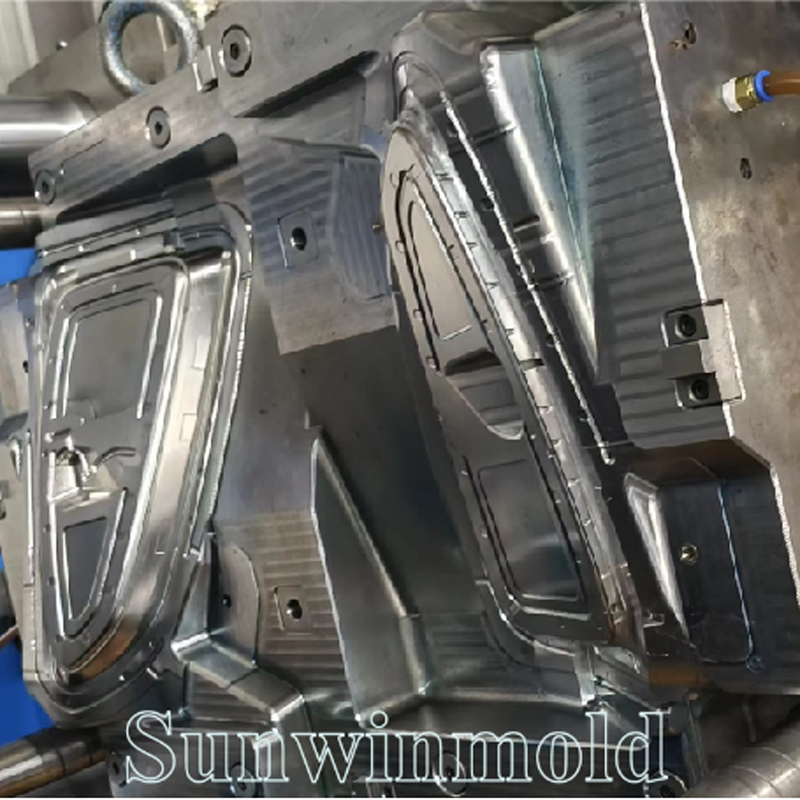

1. We are able to manufacture PET preform molds with 2-72 cavities to provide effective solutions for our customers; 2. Tailor-made product design: We have a professional design team that can design the product shape you want according to your technical requirements; 3. Cooling system: For multi-cavity preform molds, if necessary, we use flipped water channels to ensure that each preform gets a cooling effect; 4. Beautiful appearance: In order to beautify the appearance of the product, we use the hot runner valve gate as our preform product, so that the tail of the gate is short, smooth and beautiful; 5. High transparency: Our preform molds are mirror polished, as well as proper temperature control to ensure that the final PET preform has very high transparency.| Type | preform weight (g) | bottle neck (mm) | mould Height(mm) | mould width(mm) | mould thickness(mm) | mould weight (kg) | cycle time (sec) |

| 2 (1*2) | 720 | 55 | 470 | 300 | 608 | 330 | 125 |

| 4 (2*2) | 720 | 55 | 490 | 480 | 730 | 440 | 130 |

| 8 (2*4) | 16 | 28 | 450 | 350 | 410 | 475 | 18 |

| 12 (2*6) | 16 | 28 | 600 | 350 | 415 | 625 | 18 |

| 16 (2*8) | 21 | 28 | 730 | 380 | 445 | 690 | 22 |

| 24 (3*8) | 28 | 28 | 770 | 460 | 457 | 1070 | 28 |

| 32 (4*8) | 36 | 28 | 810 | 590 | 515 | 1590 | 28 |

| 48 (4*12) | 36 | 28 | 1070 | 590 | 535 | 2286 | 30 |

1. Mold features: 1. We specialize in the production of needle valve moulds, which do not require manual cutting. 2. The use of advanced hot runner system ensures that the AA value of the product is at a low level. 3. Reasonable cooling water channel design strengthens the cooling effect of the mold and effectively shortens the injection molding cycle. 2. Material selection: 1. The main parts of the mold are made of imported S136 material (Sweden-Sabak). 2. The mold base material adopts imported P20 material and electroplating treatment, which improves the corrosion resistance of the mold and prolongs the service life of the mold. 3. The heat treatment of the parts is processed in a vacuum furnace imported from Germany, and the hardness of the parts is guaranteed to be at HRC45°-48°. 3. Advanced processing equipment: The company has introduced a number of machine tools imported from the United States and Japan, such as machining centers, CNC lathes, EDM, etc., to ensure the machining accuracy of the parts and make the parts have good interchangeability. , the weight error is less than 0.3g, 2-5 molds can be produced in one minute, and the service life can reach 2 million mold times.

1. Mold features: 1. We specialize in the production of needle valve moulds, which do not require manual cutting. 2. The use of advanced hot runner system ensures that the AA value of the product is at a low level. 3. Reasonable cooling water channel design strengthens the cooling effect of the mold and effectively shortens the injection molding cycle. 2. Material selection: 1. The main parts of the mold are made of imported S136 material (Sweden-Sabak). 2. The mold base material adopts imported P20 material and electroplating treatment, which improves the corrosion resistance of the mold and prolongs the service life of the mold. 3. The heat treatment of the parts is processed in a vacuum furnace imported from Germany, and the hardness of the parts is guaranteed to be at HRC45°-48°. 3. Advanced processing equipment: The company has introduced a number of machine tools imported from the United States and Japan, such as machining centers, CNC lathes, EDM, etc., to ensure the machining accuracy of the parts and make the parts have good interchangeability. , the weight error is less than 0.3g, 2-5 molds can be produced in one minute, and the service life can reach 2 million mold times.