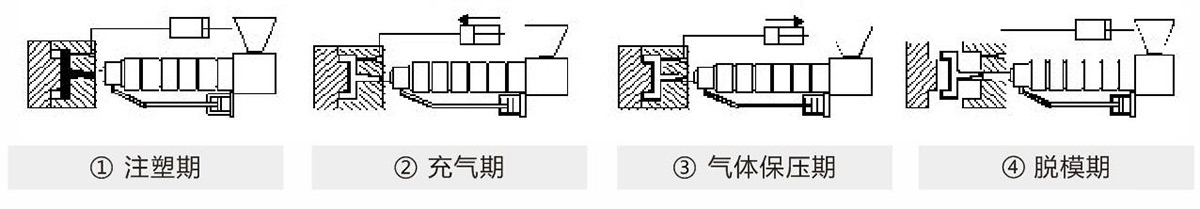

Gas-assisted injection cycle table

The gas-assisted process is a relatively complicated process. In general, the product is filled first, then the high-pressure inert gas is blown, the raw material in a semi-molten state is blown out, and the gas is used instead of the injection molding machine to obtain the product. Become a gas-assisted molding. Gas-assisted molding can also be solved by unconventional methods, such as injecting nitrogen into the mold at 70%-80% immediately, and using nitrogen-assisted molding for the filled position. This process is also a conventional process and can be used if necessary. The number of modules in the gas-assisted mold is mostly 1*1. The number of mold cavities will cause the rubber or the intake air to be unstable. This process is difficult to adjust. When it is produced normally, it will produce a high scrap rate. Therefore, it is generally recommended. Modular cavity structure. If you design a 1+1 mold structure, you need two separate air inlets for the two-point needle valve. Two gas-assisted controllers are required, which will stabilize the product.

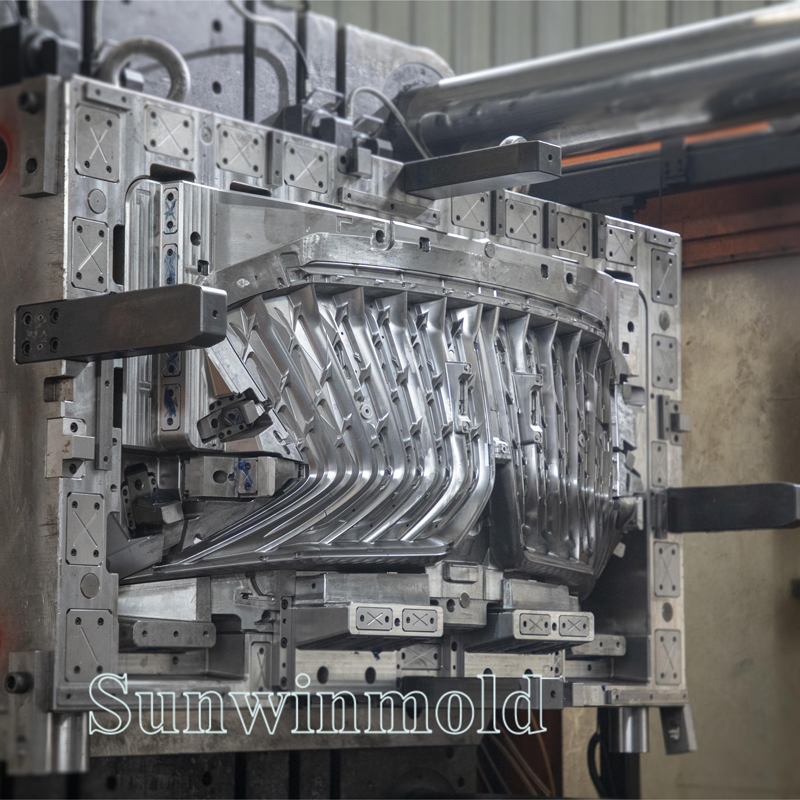

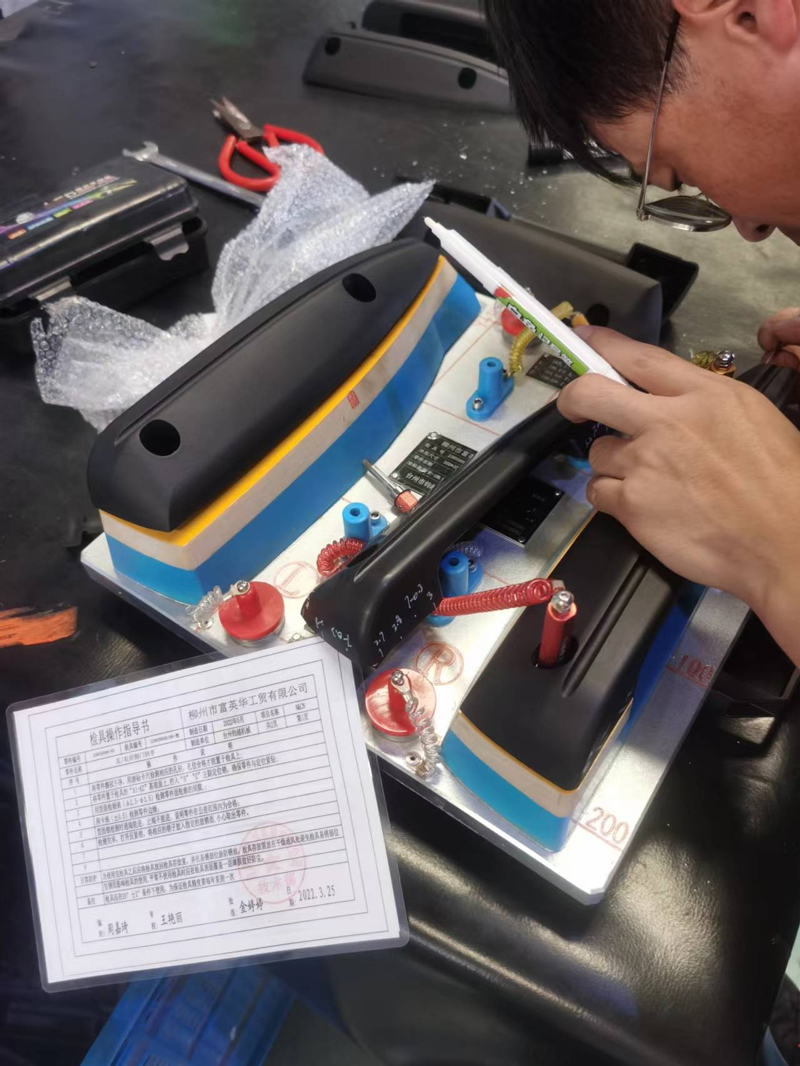

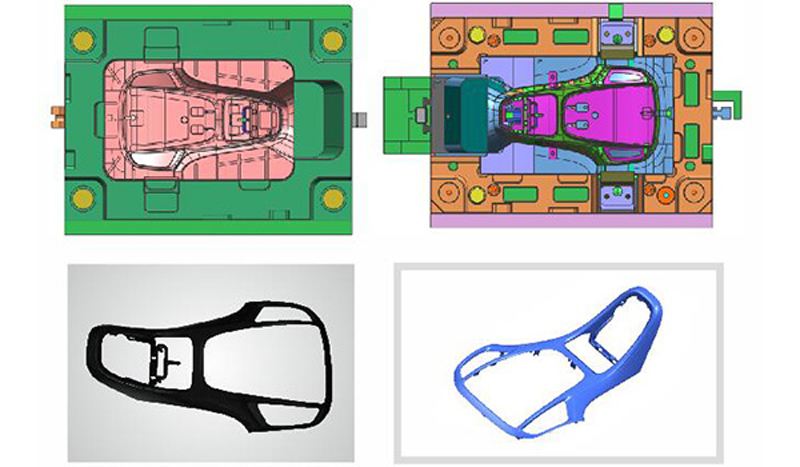

The gas-assisted process is a relatively complicated process. In general, the product is filled first, then the high-pressure inert gas is blown, the raw material in a semi-molten state is blown out, and the gas is used instead of the injection molding machine to obtain the product. Become a gas-assisted molding. Gas-assisted molding can also be solved by unconventional methods, such as injecting nitrogen into the mold at 70%-80% immediately, and using nitrogen-assisted molding for the filled position. This process is also a conventional process and can be used if necessary. The number of modules in the gas-assisted mold is mostly 1*1. The number of mold cavities will cause the rubber or the intake air to be unstable. This process is difficult to adjust. When it is produced normally, it will produce a high scrap rate. Therefore, it is generally recommended. Modular cavity structure. If you design a 1+1 mold structure, you need two separate air inlets for the two-point needle valve. Two gas-assisted controllers are required, which will stabilize the product. gas assisted plastic injection mold case show

Gas-Assisted Injection Molding Process

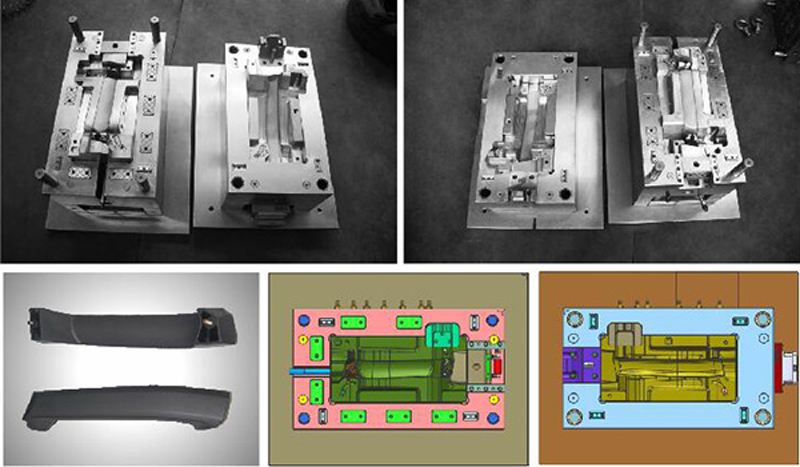

Gas-assisted injection molding is roughly divided into 4 stages: plastic injection, gas injection, pressure-holding cooling, and gas discharge. 1. First, the plastic melt is injected into the mold cavity until the melt fills from 70% to 90% of the mold cavity. The temperature of the melt is lower, and the cavity walls form a thinner curing layer. Compared to the conventional molding process, the required molding pressure is low because the cavity is only partially filled, and the air channel in the mold also facilitates the flow of the melt. If the molding pressure is too high and too much material is used, it is easy to cause melt accumulation and sink marks in places with too much material; if the material is too little, it will cause blow through. 2. Gas injection: A gas with a certain volume or pressure (generally nitrogen gas) is injected into the chamber. In this stage, the switching time to switch from melt to nitrogen injection, and correctly determine the gas pressure, related to the product quality, this stage may appear many gas injection product defects, the short delay switch is to control the thickness of the condensate layer, adjust the gas flow space, cooling the gate plastic to prevent gas flow (gas flow from the gate system rather than the preset air channel 3. Pressure-holding cooling: After the cavity and gas must be filled with a certain gas pressure, from inside to outside, to ensure that the outer surface of the product is close to the mold wall; and through the second penetration of the gas (the gas continues into the plastic interior), to make up for the internal cooling contraction of the product, pressure protection generally includes high pressure holding and low pressure holding two stages. 4. Air discharge: After the product is firmly cooled and formed, the gas in the cavity and the core can be discharged through the exhaust needle or spray, and then open the mold to remove the product. It should be noted that the injection gas in the gas-assisted injection molding process must be discharged before the mold is opened. If the pressure gas is not discharged in time, the product will expand or even break.Water assisted plastic injection mold case show

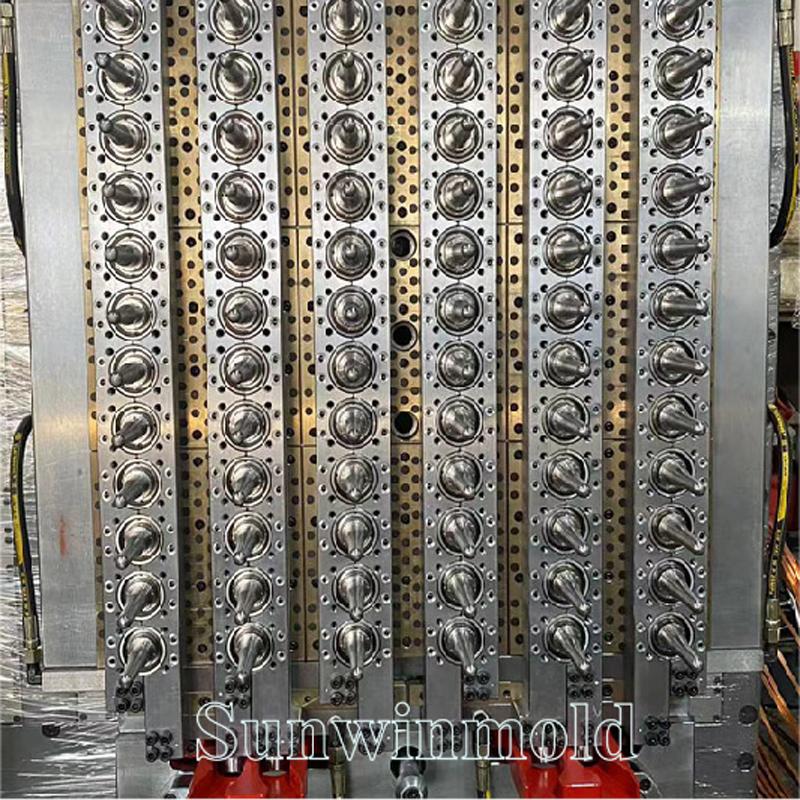

1. Water assisted injection molding using water, water injection molding can be recycled and reused, so the medium water of the two forming processes water is cheaper than nitrogen; 2. The cost of water auxiliary injection molding equipment is nearly 10 times higher than that of gas-assisted injection molding. At present, water auxiliary injection molding can only be imported; 3. Water-assisted injection molding can only be used for full injection, not for short injection molding; 4. The application of plastic materials in gas-assisted injection molding process is more widely used than that in water-assisted injection molding process;

1. Water assisted injection molding using water, water injection molding can be recycled and reused, so the medium water of the two forming processes water is cheaper than nitrogen; 2. The cost of water auxiliary injection molding equipment is nearly 10 times higher than that of gas-assisted injection molding. At present, water auxiliary injection molding can only be imported; 3. Water-assisted injection molding can only be used for full injection, not for short injection molding; 4. The application of plastic materials in gas-assisted injection molding process is more widely used than that in water-assisted injection molding process;