- Home

- Reverse Injection Molding

Reverse Injection Molding Manufacturer: Quality and Custom Solutions for Your Product Needs

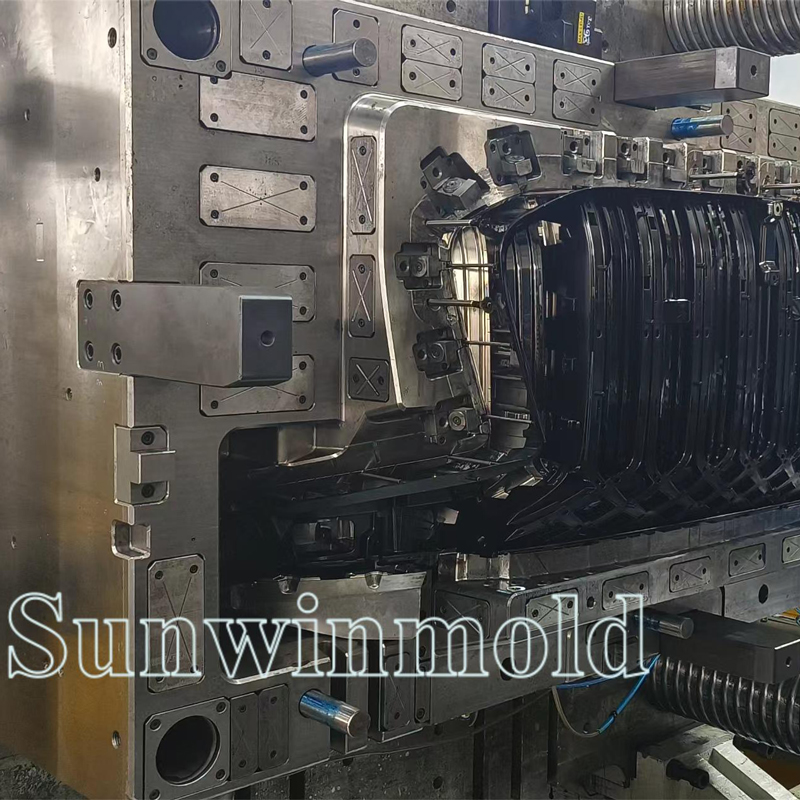

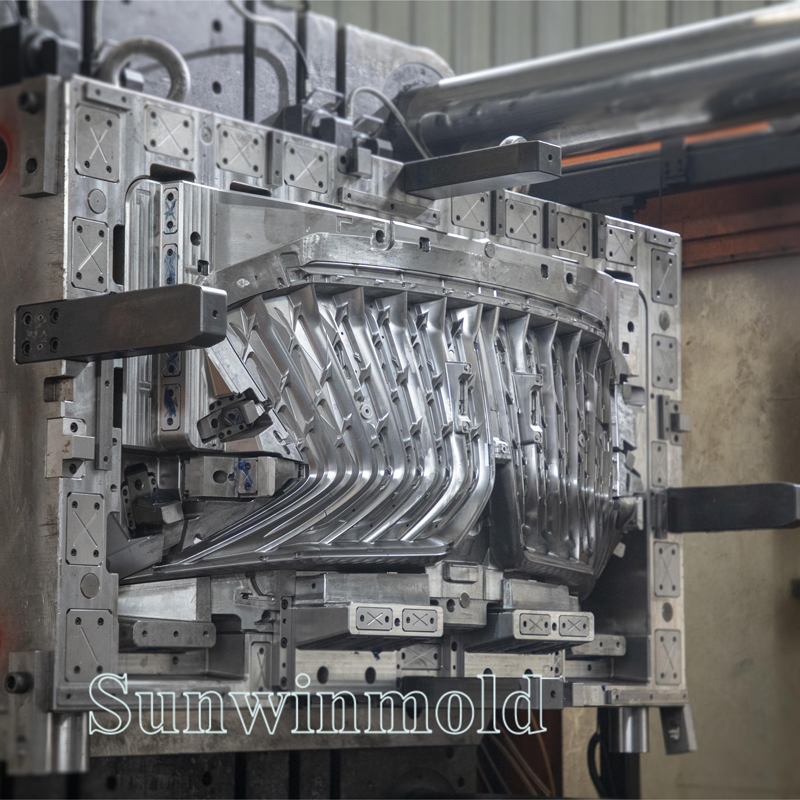

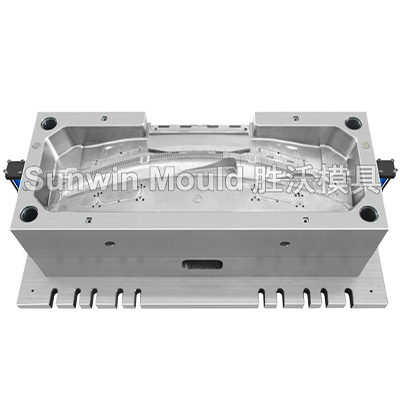

Taizhou Huangyan Sunwin Mould Co., Ltd., a leading manufacturer and supplier from China, is proud to introduce our latest product, the Reverse Injection Molding. This innovative manufacturing process takes traditional injection molding technology and flips it, resulting in a superior and more efficient process.

Reverse Injection Molding is a cutting-edge technology that offers numerous benefits. Compared to traditional injection molding methods, this process offers better control of the cooling process, resulting in faster and more consistent production times. It also allows for the use of more complex molds, giving designers more freedom to create intricate designs and shapes.

In addition, Reverse Injection Molding produces fewer defects and waste, saving on material and production costs. It is perfect for manufacturing small or intricate components used in industries such as automotive, electronics, and medical equipment.

We at Taizhou Huangyan Sunwin Mould Co., Ltd. pride ourselves on providing our clients with the highest quality products and services. By utilizing Reverse Injection Molding, we can offer even more efficient and effective solutions to meet your manufacturing needs. Contact us today to learn more about our Reverse Injection Molding capabilities.

Taizhou huangyan Sunwin Mould Co., Ltd.

Company News

Related News

SMC Compression Mould

Shop our high-quality SMC Compression Moulds. We are a leading manufacturer and supplier from a factory with a reputation for excellence. Browse now!

Plastic Test Tube Mould

Looking for a reliable plastic test tube mould factory? Look no further! We offer high-quality products and exceptional service. Contact us today!

Overmoulding & 2k Moulding

Discover top-quality overmoulding and 2k moulding products at our factory. We offer innovative solutions with precision and efficiency. Contact us now!

Plastic Expand Mould

Looking for high-quality plastic expand moulds? Look no further! We are a factory specializing in manufacturing these moulds. Order now for durable and efficient products!

Sunwin Mold Company Spool Mould

Looking for high-quality spool molds? Sunwin Mold Company is a reliable factory producing premium spool molds to meet your specific needs.

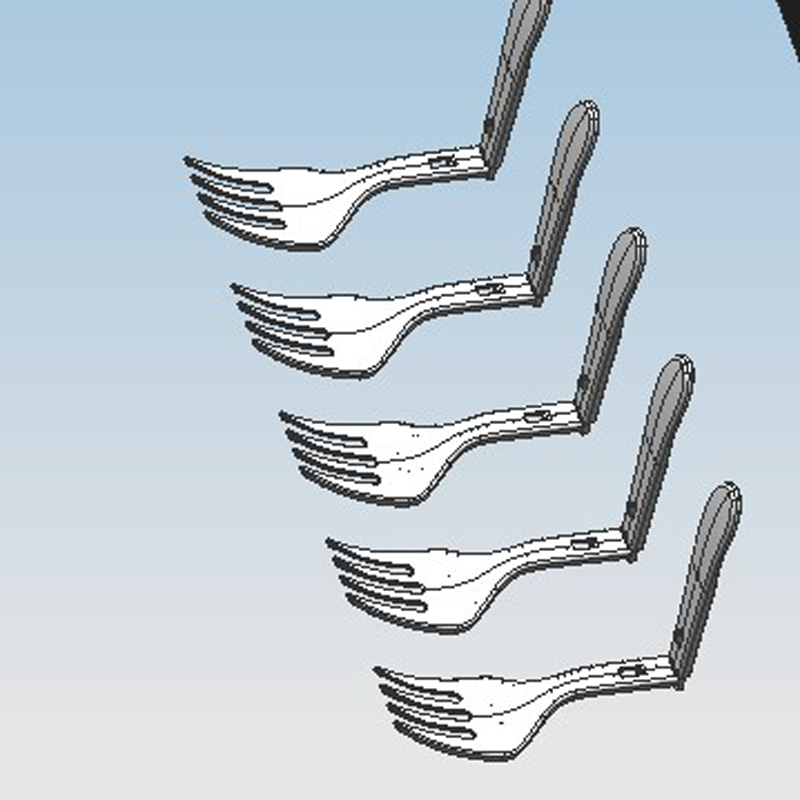

Plastic Fork Mould

We are a leading plastic fork mould factory, specializing in designing and manufacturing high-quality molds for plastic forks. Order our durable and precise molds today!

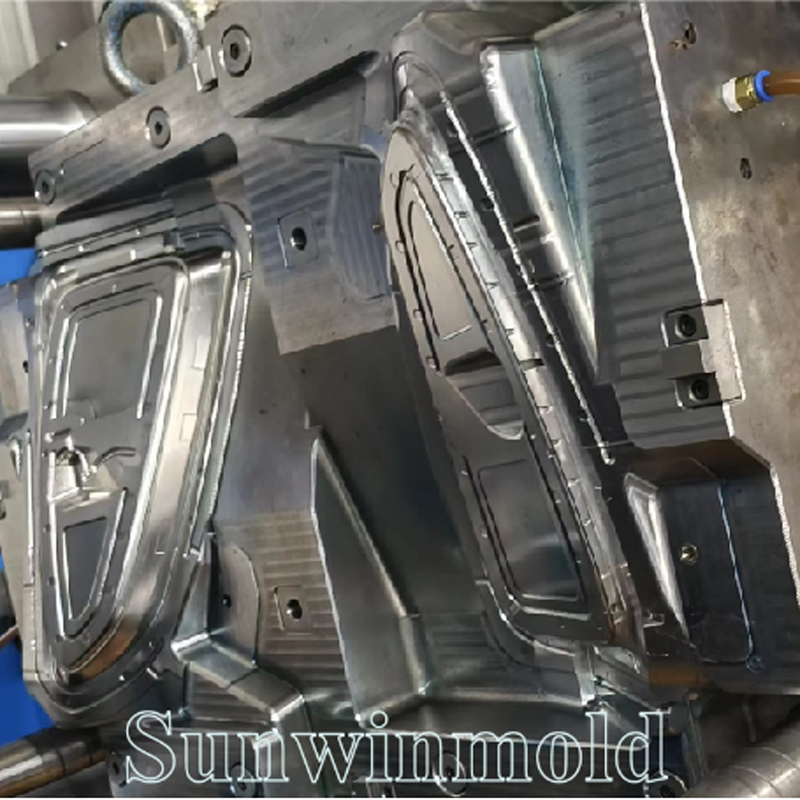

Automotive Exterior Trim Parts Mould

Looking for high-quality Automotive Exterior Trim Parts Mould? Look no further! We are a factory specializing in manufacturing top-notch moulds for all your automotive needs.

High Gloss Mould

Shop our high gloss moulds directly from the factory. Our products are meticulously crafted for superior quality and durability.

Automotive Front Bumper Mold

Looking for a reliable Automotive Front Bumper Mold factory? Look no further! We specialize in manufacturing top-quality molds for all your automotive needs.

Automotive Center Storage Box Mould

Looking for an Automotive Center Storage Box Mould? We are a factory offering high-quality molds, providing efficient storage solutions for your automotive needs.

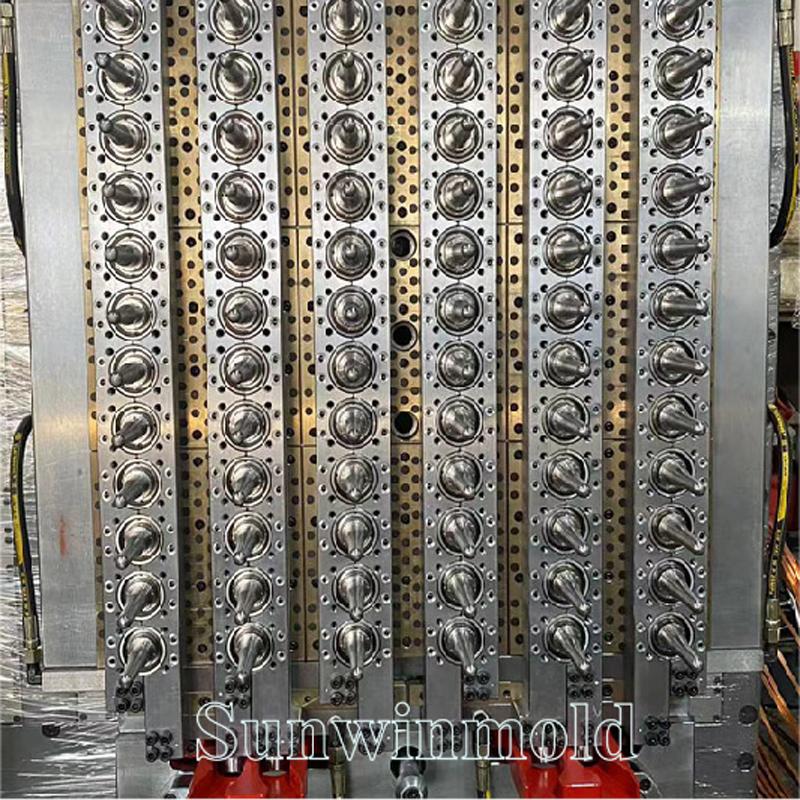

72 Cavity PET Preform Mould

Looking for a reliable factory for high-quality 72 Cavity PET Preform Moulds? Look no further! We offer competitive prices and excellent service.

Plastic Measuring Cup Mould

Buy top-quality plastic measuring cup moulds from our factory. We offer durable and precise moulds for accurate measurements. Shop now!

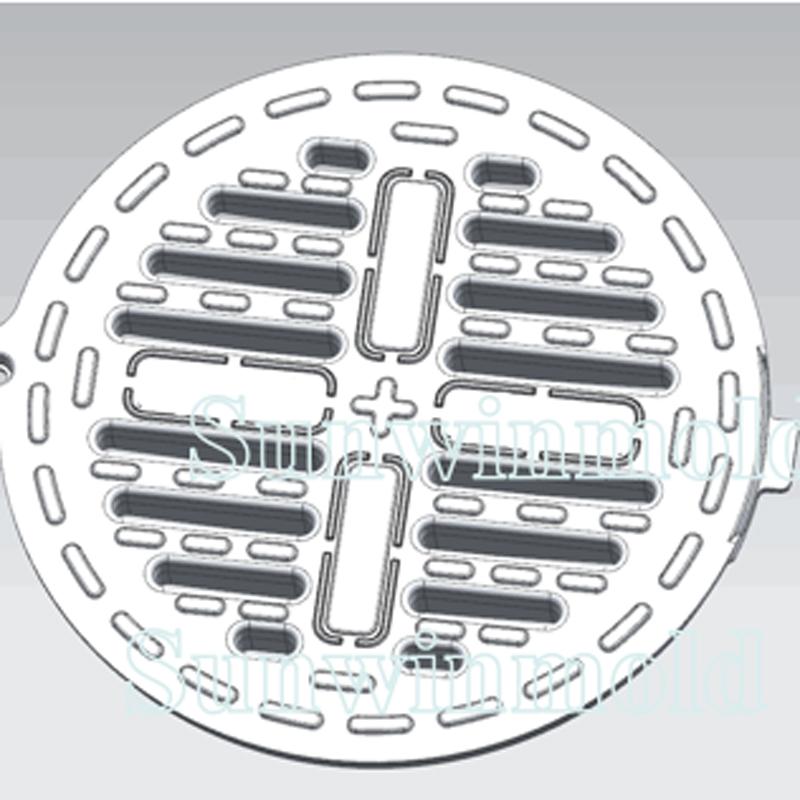

Automotive Plastic Grille Mould

Looking for quality Automotive Plastic Grille Mould? Look no further! We are a leading factory specializing in manufacturing top-notch grille molds.

Automotive Grille Mould

Looking for high-quality Automotive Grille Moulds? Look no further! We are a factory known for producing top-notch grille moulds. Order yours today!

Car Lamp Decorative Frame Mould

Looking for a high-quality Car Lamp Decorative Frame Mould? Look no further! We are a factory specializing in producing top-notch moulds.

- Manufacturer offering Reverse Injection Molding for OEM clients in China

- Reviews

- Related Videos

Introducing the revolutionary Reverse Injection Molding system, a game-changer in the manufacturing industry. This groundbreaking technology brings a new dimension to traditional injection molding, enabling innovative and efficient production processes. Reverse Injection Molding redefines how products are crafted, offering a unique approach that optimizes efficiency and reduces costs. This cutting-edge system harnesses the power of advanced engineering to produce intricate designs and complex geometries with unparalleled precision. By leveraging the principles of Reverse Injection Molding, our product ensures that every detail of your design is faithfully reproduced. The process begins by injecting a specially formulated material into a meticulously crafted mold. Unlike traditional methods, where the material is forced into the mold, Reverse Injection Molding introduces a novel mechanism that precisely extracts the material from the mold, bringing your intricate design to life. This revolutionary technology opens up a world of possibilities for manufacturers across industries. Whether you're looking to produce intricate plastic components for automotive applications, precise medical device parts, or intricate consumer electronics casings, Reverse Injection Molding offers the versatility and precision required. Not only does Reverse Injection Molding allow for complex designs, but it also significantly reduces material waste. The extraction mechanism ensures that every ounce of material is utilized, improving sustainability and cost-effectiveness. Additionally, the streamlined production process reduces cycle times and enables faster time-to-market, giving your business a competitive edge. Experience the future of manufacturing with Reverse Injection Molding. Embrace innovation, unlock design possibilities, and maximize productivity. Stay ahead of the curve and join the growing list of industry leaders who have already revolutionized their production processes with this game-changing technology.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours