Top Tips for High-Quality Basket Moulds

By:Admin

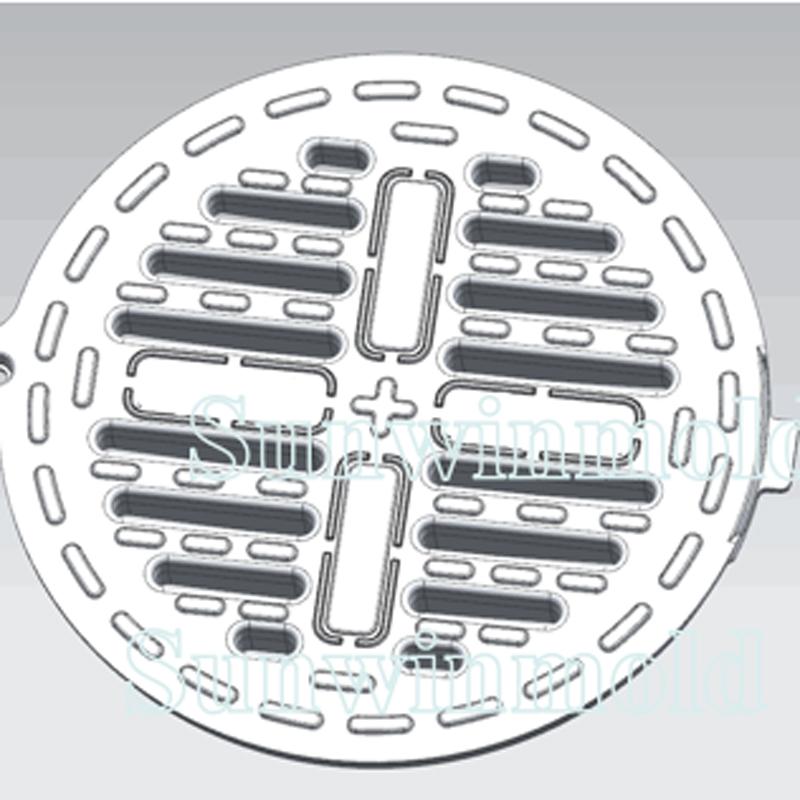

The new basket mould is the result of extensive research and development, aimed at creating a mould that is not only highly durable and reliable, but also capable of producing high-quality plastic products. The mould has been designed with precision engineering and innovative technology, making it ideal for the production of a wide range of basket designs and sizes.

One of the key features of the new basket mould is its ability to produce baskets with intricate and complex designs. This is made possible by the mould's advanced cooling system, which ensures that the plastic material is evenly distributed and solidified, resulting in a flawless finish. Additionally, the mould is equipped with a quick release mechanism, allowing for easy removal of the finished products without any damage.

In addition to its technical capabilities, the new basket mould also offers a number of practical benefits for businesses. Its high-speed production capabilities and superior efficiency make it a cost-effective solution for companies looking to streamline their manufacturing processes. Furthermore, the mould's robust construction and long lifespan ensure that it will deliver consistent performance over an extended period of time.

"We are thrilled to introduce our latest innovation, the basket mould," said the spokesperson for Basket Mould Company. "This new product is the result of our ongoing commitment to research and development, as well as our dedication to meeting the evolving needs of our customers. We are confident that the basket mould will be a valuable addition to our product line and will provide our clients with a competitive edge in the market."

Basket Mould Company takes pride in its ability to provide comprehensive support to its customers, from the initial consultation to the final delivery of the mould. The company's team of experienced engineers and technicians work closely with clients to understand their specific requirements and ensure that the mould is tailored to their exact specifications. Additionally, Basket Mould Company offers ongoing maintenance and technical support to ensure that the mould operates at its optimal performance throughout its lifespan.

As a global leader in the mould manufacturing industry, Basket Mould Company has built a solid reputation for delivering top-quality products and exceptional customer service. The company's dedication to excellence and innovation has earned it a loyal customer base and has positioned it as a preferred supplier for businesses seeking reliable and high-performance moulds.

With the introduction of the new basket mould, Basket Mould Company continues to set the standard for excellence in the industry. The company's commitment to quality, efficiency, and customer satisfaction is reflected in every product it delivers, and the new basket mould is no exception. As businesses continue to seek competitive advantages in their respective markets, Basket Mould Company remains a trusted partner, providing innovative solutions to support their success.

In conclusion, the launch of the new basket mould represents a significant milestone for Basket Mould Company and underscores the company's ongoing commitment to driving innovation and delivering value to its customers. With its advanced technology and practical advantages, the basket mould is poised to become a game-changer in the plastic industry, offering businesses a powerful tool for enhancing their production capabilities and staying ahead of the competition.

Company News & Blog

China Poultry Packaging Box Mold Manufacturer Offers High-Quality Products

China Poultry Boxes Mould Manufacturer Leads the Way in Innovative Food Packaging SolutionsAs the demand for safe and sustainable food packaging continues to soar around the world, China has emerged as a prominent player in the industry. Among the many manufacturers, one company stands out for its ability to deliver cutting-edge solutions and cater to the unique needs of the global market - China Poultry Boxes Mould Manufacturer (hereafter referred to as CPC).CPC has established itself as a leading figure in the sector, driven by its commitment to innovation, quality craftsmanship, and customer satisfaction. With years of experience in the industry, the company has gained a deep understanding of the evolving demands of the poultry packaging market. By leveraging its expertise, CPC has successfully developed a range of high-quality poultry boxes moulds that have gained recognition both domestically and internationally.One of the key reasons behind CPC's success is its unwavering focus on innovation. The company employs a team of experienced designers and engineers who constantly strive to improve existing mould designs and develop new ones that are tailored to meet the unique requirements of the poultry industry. This dedication to innovation allows CPC to provide its customers with packaging solutions that not only keep their products fresh but also enhance their brand image.In addition to its commitment to innovation, CPC is known for its uncompromising approach to quality craftsmanship. The company utilizes advanced manufacturing techniques and top-of-the-line materials to produce moulds that meet the highest standards of quality. Rigorous quality control measures are followed at every stage of the production process, ensuring that each mould is free from defects and capable of withstanding the demands of the poultry packaging industry.Furthermore, CPC understands the significance of sustainability in today's environmentally conscious world. The company actively works towards reducing its environmental footprint by adopting eco-friendly practices in its manufacturing processes. CPC's moulds are designed to be reusable and highly durable, reducing waste and promoting a circular economy. By investing in sustainable packaging solutions, CPC both meets market demands and contributes to a greener and more sustainable future.CPC's dedication to customer satisfaction is another factor that sets it apart from its competitors. The company understands that each customer has unique requirements and consistently strives to meet these needs. By engaging in close collaboration with its clients, CPC ensures that its moulds are customized to their specifications, guaranteeing a perfect fit for their poultry packaging needs. The company also provides exceptional customer support services, ensuring a smooth and hassle-free experience for its clients.The success of CPC's innovative and high-quality moulds has not gone unnoticed. The products have gained significant recognition in both domestic and international markets, making the company a preferred choice among poultry packaging manufacturers. CPC's moulds have been exported to various countries, which is a testament to the company's commitment to delivering world-class products that meet global standards.Looking ahead, CPC shows no signs of slowing down its quest for innovation and excellence. The company is continuously exploring new technologies and materials to develop even more advanced and sustainable food packaging solutions. By keeping abreast of industry trends and customer demands, CPC aims to remain at the forefront of the poultry packaging market and continue its mission to provide safe, efficient, and eco-friendly packaging solutions.In conclusion, China Poultry Boxes Mould Manufacturer has established itself as a leading player in the global food packaging industry. Through its unwavering commitment to innovation, quality craftsmanship, sustainability, and customer satisfaction, CPC has become the go-to choice for poultry packaging manufacturers worldwide. With a focus on continuous improvement and a dedication to meeting the evolving demands of customers, CPC is set to shape the future of the industry and contribute to a more sustainable and efficient food packaging ecosystem.

Top Tips for High-Quality Basket Moulds

Basket Mould Company, a leading manufacturer of high-quality moulds for the plastic industry, is pleased to announce the launch of their latest product, a state-of-the-art basket mould. With over 20 years of experience in the industry, Basket Mould Company has established itself as a trusted and reliable supplier of moulds to businesses around the world.The new basket mould is the result of extensive research and development, aimed at creating a mould that is not only highly durable and reliable, but also capable of producing high-quality plastic products. The mould has been designed with precision engineering and innovative technology, making it ideal for the production of a wide range of basket designs and sizes.One of the key features of the new basket mould is its ability to produce baskets with intricate and complex designs. This is made possible by the mould's advanced cooling system, which ensures that the plastic material is evenly distributed and solidified, resulting in a flawless finish. Additionally, the mould is equipped with a quick release mechanism, allowing for easy removal of the finished products without any damage.In addition to its technical capabilities, the new basket mould also offers a number of practical benefits for businesses. Its high-speed production capabilities and superior efficiency make it a cost-effective solution for companies looking to streamline their manufacturing processes. Furthermore, the mould's robust construction and long lifespan ensure that it will deliver consistent performance over an extended period of time."We are thrilled to introduce our latest innovation, the basket mould," said the spokesperson for Basket Mould Company. "This new product is the result of our ongoing commitment to research and development, as well as our dedication to meeting the evolving needs of our customers. We are confident that the basket mould will be a valuable addition to our product line and will provide our clients with a competitive edge in the market."Basket Mould Company takes pride in its ability to provide comprehensive support to its customers, from the initial consultation to the final delivery of the mould. The company's team of experienced engineers and technicians work closely with clients to understand their specific requirements and ensure that the mould is tailored to their exact specifications. Additionally, Basket Mould Company offers ongoing maintenance and technical support to ensure that the mould operates at its optimal performance throughout its lifespan.As a global leader in the mould manufacturing industry, Basket Mould Company has built a solid reputation for delivering top-quality products and exceptional customer service. The company's dedication to excellence and innovation has earned it a loyal customer base and has positioned it as a preferred supplier for businesses seeking reliable and high-performance moulds.With the introduction of the new basket mould, Basket Mould Company continues to set the standard for excellence in the industry. The company's commitment to quality, efficiency, and customer satisfaction is reflected in every product it delivers, and the new basket mould is no exception. As businesses continue to seek competitive advantages in their respective markets, Basket Mould Company remains a trusted partner, providing innovative solutions to support their success.In conclusion, the launch of the new basket mould represents a significant milestone for Basket Mould Company and underscores the company's ongoing commitment to driving innovation and delivering value to its customers. With its advanced technology and practical advantages, the basket mould is poised to become a game-changer in the plastic industry, offering businesses a powerful tool for enhancing their production capabilities and staying ahead of the competition.

Injection Molding Techniques for Producing High-Quality Pp Products

Pp Injection Molding, a leading provider of high-quality plastic injection molding solutions, is pleased to announce the expansion of its production capacity with the addition of new state-of-the-art equipment. This investment in the latest technology and machinery will enable Pp Injection Molding to better serve its customers with increased efficiency and precision.Founded in {year}, Pp Injection Molding has earned a reputation for excellence in the plastic injection molding industry. With a strong commitment to innovation and customer satisfaction, the company has become a trusted partner for businesses across a wide range of industries, including automotive, consumer goods, electronics, and more.The addition of the new equipment further demonstrates Pp Injection Molding's dedication to staying at the forefront of technological advancements in the industry. By embracing the latest innovations in machinery and processes, the company is able to deliver superior results and meet the evolving needs of its customers.The new equipment includes advanced injection molding machines that offer enhanced speed, accuracy, and versatility. These state-of-the-art machines are capable of handling a wide variety of plastic resins and producing complex, high-precision parts with tight tolerances. Additionally, the equipment is equipped with advanced automation and monitoring capabilities, allowing for greater consistency and efficiency in production."We are thrilled to announce the expansion of our production capacity with the addition of new cutting-edge equipment," said [company spokesperson]. "This investment reflects our ongoing commitment to providing the highest quality plastic injection molding solutions to our customers. With these new machines, we are well-positioned to meet the growing demand for our services and deliver exceptional results with greater efficiency than ever before."In addition to the new equipment, Pp Injection Molding continues to uphold its stringent quality assurance standards and environmental sustainability practices. The company maintains ISO [insert number] certification and adheres to rigorous quality control measures throughout the production process. Furthermore, Pp Injection Molding is dedicated to reducing its environmental footprint by implementing eco-friendly manufacturing practices and utilizing recyclable materials whenever possible.As a customer-focused company, Pp Injection Molding strives to provide comprehensive support and expertise to its clients from project inception to completion. With a team of experienced engineers and technicians, the company offers design assistance, prototyping, tooling, and production services to ensure the success of each project."We take pride in our ability to collaborate closely with our customers and provide tailored solutions to meet their specific needs," [company spokesperson] added. "Our team is dedicated to delivering exceptional service and results, and we are excited to leverage our new equipment to further elevate the quality and efficiency of our operations."With its expanded production capacity and continued dedication to excellence, Pp Injection Molding is well-positioned to drive innovation and deliver exceptional plastic injection molding solutions for businesses of all sizes and industries. The company's investment in cutting-edge equipment underscores its commitment to staying ahead of the curve and providing customers with the best possible experience.

Experts predict a significant growth in the demand for high-quality industrial molds in the coming years.

[Introduction]In today's ever-evolving industrial landscape, the demand for high-quality molds is at an all-time high. Industrial Moulds, a renowned manufacturer in the industry, has been fulfilling this demand with its innovative and efficient solutions. With a rich history and a commitment to excellence, the company has successfully carved a niche for itself in the competitive mold manufacturing sector. This news article will delve into the various strengths, achievements, and future prospects of Industrial Moulds, shedding light on how it has become a key player in the global market.[Company Background]Founded in the early 1960s, Industrial Moulds has continuously strived for perfection in its line of work. With a strong focus on research and development, the company has consistently challenged traditional manufacturing practices and introduced cutting-edge technologies to optimize the mold production processes. Over the years, Industrial Moulds has expanded both in terms of infrastructure and expertise, investing heavily in state-of-the-art machinery and attracting top talent in the field. Today, it stands as a testament to the power of innovative thinking and a testament to the importance of adapting to change.[Industry Prowess]Industrial Moulds' relentless pursuit of excellence has earned it numerous accolades in the mold manufacturing industry. Its commitment to delivering superior products and providing exceptional customer service has garnered the trust and loyalty of clients across the globe. The company's diverse range of molds caters to various industries, including automotive, packaging, consumer electronics, and medical. With a comprehensive understanding of industry requirements and an ability to customize molds as per client specifications, Industrial Moulds has become a go-to choice for businesses seeking high-quality and reliable molds.[Technology and Innovation]One of the driving forces behind Industrial Moulds' success is its focus on technology and innovation. The company's dedicated research and development team continuously explore new materials, manufacturing techniques, and design methodologies. By leveraging the latest advancements in 3D modeling, computer-aided design (CAD), and simulation software, Industrial Moulds has been able to optimize mold designs, reduce production time, and enhance overall efficiency. This commitment to technological advancement has not only ensured the company's competitiveness but has also contributed to the overall advancement of the mold manufacturing industry.[Commitment to Sustainability]Industrial Moulds is acutely aware of its environmental footprint and actively takes steps to minimize it. The company adheres to strict sustainability practices by using eco-friendly materials and processes whenever possible. By adopting energy-efficient machinery and actively reducing waste throughout its operations, Industrial Moulds showcases its dedication to building a sustainable future. Such a commitment has not only resonated with clients but has also positioned the company as a responsible corporate citizen.[Future Outlook]As Industrial Moulds looks ahead, it aims to further expand its global presence and diversify its product offerings. With a strong foothold in traditional markets, the company has identified emerging markets that present substantial growth opportunities. By adding new product lines that cater to evolving industry demands, Industrial Moulds intends to stay ahead of the curve and continue delivering exceptional value to its customers. The company also plans to invest in automation and robotics to enhance productivity and maintain its competitive edge.[Conclusion]Industrial Moulds, with its rich history, commitment to excellence, and inclination towards innovation, stands as a beacon of success in the mold manufacturing industry. Its dedication to delivering high-quality molds, coupled with a focus on sustainability and growth, has solidified its position as a global leader. With a blueprint that fosters technological advancements and customer satisfaction, the future seems bright for Industrial Moulds as it continues to shape the industrial landscape with its molds, one innovation at a time.

Top Supplier of Gas Injection Moulding in China" could be rewritten as "Leading Gas Injection Moulding Supplier in China

China-based Gas Injection Moulding Supplier, one of the leading providers of gas injection moulding technology, has recently made significant strides in the global market. With its innovative solutions and a broad range of offerings, China Gas Injection Moulding Supplier has positioned itself as a reliable and capable partner for businesses seeking cost-effective and efficient moulding solutions.Gas injection moulding is a process that involves injecting gas into a mould cavity to create hollow parts with intricate designs. This technology offers several advantages over traditional moulding methods, including reduced material usage and cycle time, improved part quality and consistency, and increased design flexibility. It is widely used in various industries, such as automotive, consumer goods, electronics, and medical devices.China Gas Injection Moulding Supplier stands out in the market due to its cutting-edge technology, extensive industry experience, and dedication to customer satisfaction. The company's team of experts works closely with clients to understand their specific requirements and provide tailored solutions that meet their production needs.One of the key factors behind China Gas Injection Moulding Supplier's success is its commitment to continuous innovation. The company invests heavily in research and development to stay at the forefront of the gas injection moulding technology. By continuously improving their manufacturing processes and adopting new technologies, China Gas Injection Moulding Supplier ensures that its customers benefit from the latest advancements in the industry.Furthermore, China Gas Injection Moulding Supplier has established a strong quality management system to ensure the highest standards in its products and services. The company strictly adheres to international quality standards and has obtained various certifications, including ISO 9001. With a dedicated quality control team, China Gas Injection Moulding Supplier conducts rigorous testing and inspection at every stage of the manufacturing process to guarantee the reliability and durability of its products.In addition to its technological advancements and focus on quality, China Gas Injection Moulding Supplier boasts a robust global supply chain network. The company has built long-term partnerships with reliable raw material suppliers, ensuring a stable and uninterrupted supply of high-quality materials. This, combined with its efficient production processes and skilled workforce, enables China Gas Injection Moulding Supplier to deliver products promptly and maintain a competitive edge in the market.China Gas Injection Moulding Supplier's dedication to customer satisfaction is evident in its outstanding after-sales service. The company offers comprehensive support, including technical assistance, troubleshooting, and maintenance services, to ensure that its customers experience a smooth and problem-free production process.As a market leader, China Gas Injection Moulding Supplier is committed to sustainable and responsible manufacturing practices. The company prioritizes environmental protection and resource conservation in its operations. By leveraging innovative technologies and optimizing production processes, China Gas Injection Moulding Supplier minimizes waste generation and energy consumption, contributing to a greener planet.In conclusion, China Gas Injection Moulding Supplier has emerged as a prominent player in the global gas injection moulding market. With its advanced technology, focus on quality, efficient supply chain, and customer-oriented approach, the company continues to gain recognition and trust from customers worldwide. As the demand for gas injection moulding solutions continues to grow, China Gas Injection Moulding Supplier is well-positioned to meet the needs of businesses across various industries.

High-Quality Pallet Moulds: Essential Equipment for Efficient Warehouse Operations

Pallet Moulds, a leading manufacturer of high-quality plastic injection moulds, has been making waves in the industry with its cutting-edge technology and innovative designs. The company, with over 20 years of experience, has gained a strong reputation for delivering top-notch moulds to its global client base.Specializing in the production of pallet moulds, Pallet Moulds has established itself as a frontrunner in the market. With a state-of-the-art manufacturing facility and a team of highly skilled engineers and technicians, the company is able to produce moulds that meet the exact specifications of its clients. Whether it's for standard pallet sizes or custom designs, Pallet Moulds has the expertise and capabilities to deliver top-quality moulds on time and within budget.One of the key factors that set Pallet Moulds apart from its competitors is its dedication to research and development. The company continuously invests in new technologies and processes to improve the quality and efficiency of its moulds. This commitment to innovation has enabled Pallet Moulds to stay ahead of the curve and offer its clients the latest advancements in mould design and manufacturing.Moreover, Pallet Moulds takes great pride in its strict quality control measures. Each mould undergoes rigorous testing to ensure that it meets the highest standards of durability and performance. By adhering to strict quality standards, the company has built a solid reputation for delivering moulds that are reliable and long-lasting.In addition to its technical expertise, Pallet Moulds also prioritizes customer satisfaction. The company works closely with its clients to understand their specific needs and provide personalized solutions. Whether it's a small order or a large-scale production run, Pallet Moulds is committed to delivering exceptional service and exceeding customer expectations.Furthermore, Pallet Moulds places a strong emphasis on sustainability. The company's manufacturing processes are designed to minimize waste and reduce environmental impact. By using eco-friendly materials and energy-efficient technologies, Pallet Moulds is dedicated to creating a more sustainable future for the industry.With a strong track record of success and a commitment to excellence, Pallet Moulds is poised to continue its growth and expansion in the global market. The company's dedication to quality, innovation, and customer satisfaction sets it apart as a leader in the plastic injection moulding industry.For businesses looking for reliable and high-quality pallet moulds, Pallet Moulds stands out as a trusted partner. With its advanced technology, skilled workforce, and unwavering commitment to excellence, the company is well-equipped to meet the demands of the ever-evolving industry.In conclusion, Pallet Moulds has solidified its position as a top-tier manufacturer of plastic injection moulds, with a focus on pallet moulds. With its dedication to innovation, quality, customer satisfaction, and sustainability, the company continues to set the standard for excellence in the industry. As Pallet Moulds continues to grow and expand its global presence, it remains a trusted and reliable partner for businesses seeking top-quality moulds for their operations.

Understanding the Cost of Injection Moulding Die: Factors to Consider

Injection Moulding Die Cost: A Key Factor in Manufacturing SuccessInjection moulding is a widely used manufacturing process in which melted material is injected into a mould, which then cools and solidifies to form a specific shape. This process is commonly used to produce a variety of items, including plastic components, toys, and medical devices. The cost of injection moulding dies is a key factor in the overall production cost and can significantly impact the profitability of a manufacturing operation.Choosing the right company for injection moulding die production is crucial for ensuring high-quality, cost-effective manufacturing. That's where [Company Name], a leader in the injection moulding industry, comes into play.[Company Name] is a renowned company with a long history of providing top-quality injection moulding dies for a wide range of industries. With state-of-the-art technology and a team of skilled engineers, [Company Name] has a proven track record of delivering high-performance moulds that meet the specific needs of its customers.The cost of injection moulding dies is a complex consideration that involves several factors. The initial design and manufacturing of the die, as well as overhead costs and material expenses, all play a role in determining the overall cost. Factors such as die complexity, material type, and production volume can all impact the final cost of the mould.When it comes to choosing a company for injection moulding die production, it's crucial to consider not only the cost but also the quality and reliability of the products. [Company Name] prides itself on offering competitive pricing without compromising on the quality of its moulds. By leveraging its extensive experience and technical expertise, [Company Name] is able to deliver cost-effective solutions that meet the highest industry standards.In addition to providing high-quality injection moulding dies, [Company Name] also offers a range of services to support its customers throughout the manufacturing process. From initial design and prototyping to production and post-sale support, [Company Name] is dedicated to helping its customers achieve success in their manufacturing operations.The choice of company for injection moulding die production can have a significant impact on the overall efficiency and profitability of a manufacturing operation. By partnering with a reliable and experienced company like [Company Name], manufacturers can benefit from cost-effective solutions that meet their specific needs and deliver superior performance.In conclusion, the cost of injection moulding dies is a crucial consideration for manufacturers looking to optimize their production processes. Choosing the right company for die production is essential for ensuring high-quality, cost-effective manufacturing. With its proven track record, technical expertise, and commitment to customer satisfaction, [Company Name] is well-positioned to meet the diverse needs of its customers and contribute to their success in the injection moulding industry.

Top Quality Industrial Crate Moulds Made in China: Expert Insights

China's Industrial Crate Mould - A Revolutionary Solution for the Manufacturing SectorAs the manufacturing sector continues to evolve, companies are continuously seeking innovative solutions to enhance efficiency and streamline their operations. One such solution that has gained significant attention is the China Industrial Crate Mould. This revolutionary moulding technology has transformed the manufacturing process, offering numerous benefits to companies across various industries.China has long been recognized as a global manufacturing powerhouse, and the introduction of the Industrial Crate Mould is further strengthening this status. By eliminating the need for traditional manufacturing methods, such as welding and joining, this mould offers unparalleled ease and efficiency in production.The Industrial Crate Mould offers remarkable design flexibility, allowing manufacturers to create customized and intricate designs for a wide range of industrial crates. These crates are widely used in sectors such as logistics, transportation, warehousing, and more, making them a crucial component of supply chain management. With the advancement of the Industrial Crate Mould, manufacturers can now produce crates of superior quality, meeting the demands of various industries.One of the key advantages of the Industrial Crate Mould is its cost-effectiveness. Traditional manufacturing methods often require significant investment in machinery, labor, and maintenance. The introduction of this mould eliminates these expenses, as it operates on advanced automated systems and requires minimal human intervention. This streamlined production process not only reduces costs but also enhances the overall productivity of manufacturing units.Furthermore, the Industrial Crate Mould guarantees uniformity and consistency in the manufacturing process. With precise measurements and standardized production techniques, manufacturers can ensure that every crate produced meets the highest quality standards. This eliminates the risk of human error and ensures that the final product is reliable, sturdy, and durable.The Industrial Crate Mould is a significant step towards sustainable manufacturing practices. By utilizing eco-friendly materials and minimizing waste generation, this mould addresses the growing concerns of environmental degradation. Its advanced features allow for maximum material utilization, reducing waste and promoting sustainable manufacturing principles.In addition to its environmental benefits, the Industrial Crate Mould also offers improved safety features. Traditional manufacturing processes, such as welding, pose significant safety hazards to workers. The use of advanced moulding technology eliminates the need for such hazardous operations, ensuring a safer working environment for employees.China's Industrial Crate Mould has gained widespread recognition and popularity in the global market. With its state-of-the-art technology and efficient production capabilities, it has become a preferred choice for companies worldwide. This mould not only enhances manufacturing efficiency but also helps businesses meet stringent quality requirements.Leading companies in China's mould manufacturing industry, such as [Company Name], have made significant contributions to the development and advancement of the Industrial Crate Mould. With their expertise and innovative approach, these companies have paved the way for a more efficient and sustainable manufacturing sector.In conclusion, the introduction of the China Industrial Crate Mould has revolutionized the manufacturing process. Offering numerous benefits such as cost-effectiveness, design flexibility, improved safety, and environmental sustainability, this mould has become an indispensable tool for companies across various industries. As the manufacturing sector continues to evolve, the Industrial Crate Mould is poised to play a pivotal role in shaping the future of manufacturing worldwide.

How to Choose the Best Plastic Moulding Die Maker for Your Project

[Company Name], a leading manufacturer in the plastic moulding industry, has announced the addition of a new Plastic Moulding Die Maker to its team. The company has been at the forefront of innovation and quality in the plastic moulding industry, and the addition of the new Die Maker will further enhance its capabilities in providing top-notch products to its clients.The Plastic Moulding Die Maker will be responsible for designing and creating moulds that will be used in the production of plastic products. This is a critical role in the manufacturing process, as the quality and precision of the moulds directly impact the quality of the final products. With the expertise and experience of the new Die Maker, [Company Name] aims to further improve its manufacturing processes and exceed customer expectations.[Company Name] is known for its commitment to excellence in all aspects of its business. The company has a state-of-the-art manufacturing facility that is equipped with the latest technology and machinery to ensure that its products are of the highest quality. In addition to this, the company also places a strong emphasis on research and development, constantly looking for new and innovative ways to improve its products and processes.The addition of the new Plastic Moulding Die Maker is a testament to [Company Name]'s dedication to continuous improvement and excellence. The company is constantly looking for ways to enhance its capabilities and stay ahead in the competitive plastic moulding industry. By investing in top talent and expertise, [Company Name] aims to strengthen its position as a leader in the industry and provide its clients with the best possible products and services.The new Plastic Moulding Die Maker comes with a wealth of experience and expertise in the industry. With years of experience in designing and creating moulds for plastic products, the new Die Maker is expected to bring fresh perspectives and innovative ideas to [Company Name]. This will not only improve the quality of the products but also streamline the manufacturing processes, making them more efficient and cost-effective.[Company Name] is confident that the addition of the new Plastic Moulding Die Maker will help the company achieve its goals of providing top-quality products and exceeding customer expectations. The company prides itself on its ability to adapt to the changing needs and demands of the market and believes that the new Die Maker will play a crucial role in this regard.The Plastic Moulding Die Maker will be working closely with the production team to ensure that the moulds are designed and created to the highest standards. This collaboration between the design and production teams is expected to result in a seamless and efficient manufacturing process, ultimately leading to superior products for the clients of [Company Name].In addition to the focus on quality and innovation, [Company Name] is also committed to sustainability and environmental responsibility. The company recognizes the importance of reducing its environmental footprint and is constantly looking for ways to minimize waste and improve its energy efficiency. By investing in new talent and expertise, [Company Name] aims to further enhance its sustainability efforts and set new benchmarks for responsible manufacturing in the plastic moulding industry.Overall, the addition of the new Plastic Moulding Die Maker is a clear indication of [Company Name]'s commitment to excellence, innovation, and sustainability. The company is confident that the new Die Maker will make a significant impact on its operations and help it achieve its long-term goals. With a strong focus on quality, innovation, and sustainability, [Company Name] is well-positioned to continue its leadership in the plastic moulding industry and provide its clients with exceptional products and services.

High-Quality Poultry Boxes Mould for Your Packaging Needs

Poultry Boxes Mould Unveiled by Leading Manufacturing Company{Company Name} is proud to announce the launch of its latest innovation - the Poultry Boxes Mould. This new addition to the company's extensive line of moulds is set to revolutionize the poultry packaging industry with its advanced design and high-quality manufacturing.The Poultry Boxes Mould is specifically engineered to meet the unique needs of the poultry industry, providing a durable and reliable solution for packaging poultry products. The mould is made from premium materials, ensuring that it can withstand the rigors of the poultry processing and distribution process.{Company Name} has a long-standing reputation for excellence in the manufacturing industry, with a focus on producing top-quality moulds for various applications. The company's state-of-the-art manufacturing facilities and experienced team of engineers and designers ensure that each mould is precision-engineered to meet the highest standards of quality and performance.The launch of the Poultry Boxes Mould represents a significant milestone for {Company Name}, as it demonstrates the company's commitment to innovation and meeting the evolving needs of its customers. With the poultry industry experiencing rapid growth and technological advancements, {Company Name} recognized the opportunity to develop a mould that could enhance the efficiency and effectiveness of poultry packaging.The Poultry Boxes Mould offers a range of features and benefits that set it apart from traditional moulds on the market. Its durable construction means that it can withstand the demands of the poultry processing environment, including exposure to moisture, temperature variations, and handling during transportation. The mould's precision design ensures a tight and secure fit, providing optimal protection for poultry products during storage and distribution.In addition to its robust construction, the Poultry Boxes Mould also incorporates innovative design elements that enhance its functionality. The mould is engineered for easy assembly and disassembly, simplifying the packaging process and reducing downtime. Its ergonomic design also makes it easy to handle and transport, further improving operational efficiency for poultry processing and distribution facilities.{Company Name} has also placed a strong emphasis on sustainability in the development of the Poultry Boxes Mould. The mould is created using eco-friendly materials and manufacturing processes, aligning with the company's commitment to environmental responsibility. By offering a sustainable packaging solution for the poultry industry, {Company Name} aims to support its customers in their efforts to reduce their environmental footprint and meet the growing demand for eco-friendly packaging solutions.The launch of the Poultry Boxes Mould has already generated significant interest from customers in the poultry industry, with early adopters praising its performance and reliability. {Company Name} is confident that the mould will set a new standard for poultry packaging, providing a superior solution that meets the needs of modern poultry processing and distribution operations.As {Company Name} continues to expand its product offering and invest in cutting-edge manufacturing technologies, the company remains committed to delivering innovative solutions that drive the success of its customers. With the introduction of the Poultry Boxes Mould, {Company Name} has once again demonstrated its leadership and dedication to excellence in the manufacturing industry.Overall, the launch of the Poultry Boxes Mould represents a significant step forward for {Company Name}, showcasing the company's ability to anticipate market needs and develop solutions that deliver value and performance. As the poultry industry continues to evolve, {Company Name} is well-positioned to support its customers with the most advanced and reliable moulds available on the market.In conclusion, {Company Name}'s Poultry Boxes Mould is a testament to the company's unwavering commitment to innovation, quality, and customer satisfaction. With its advanced design, durability, and sustainability features, the mould is set to become a game-changer in the poultry packaging industry, offering a superior solution for poultry processing and distribution operations. As {Company Name} continues to push the boundaries of manufacturing excellence, the launch of the Poultry Boxes Mould reaffirms its position as a leading provider of innovative solutions for the global manufacturing industry.