Innovative Double Shot Injection Molding Process Unveiled in Latest Industry News

By:Admin

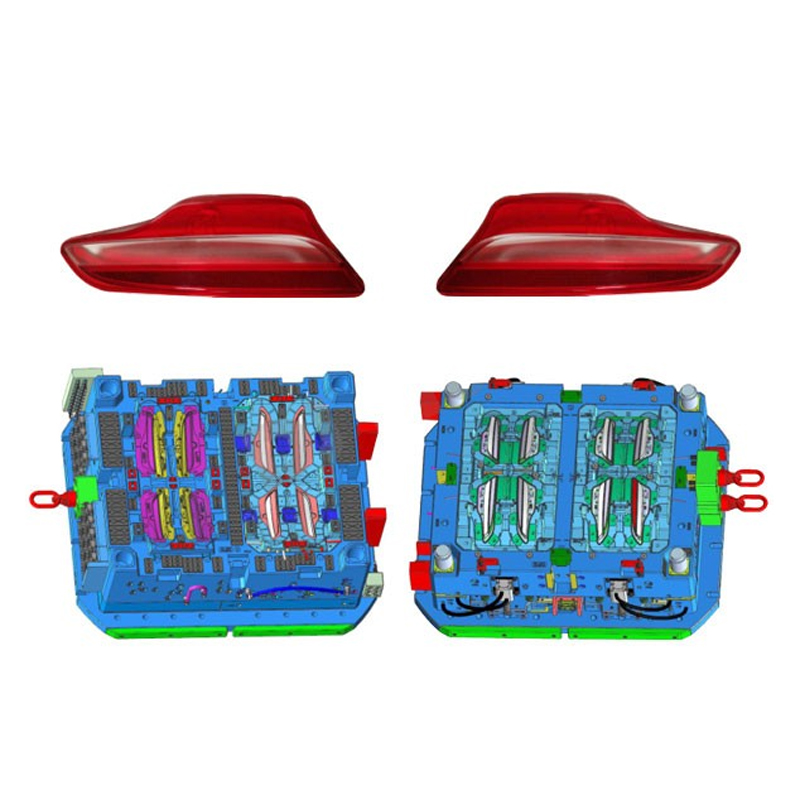

In the world of manufacturing, efficiency is key. Finding ways to produce high-quality products in a cost-effective and timely manner is the goal of every company. This is where Double Shot Injection Molding comes into play. This innovative manufacturing process is changing the game for companies looking to improve their production methods.

Double Shot Injection Molding is a process that allows for the creation of complex, multi-material products in a single operation. This means that manufacturers can produce parts that have multiple materials and colors without the need for additional assembly or bonding processes. This not only saves time and money, but also reduces the risk of defects and increases the overall quality of the product.

One company that is leading the way in Double Shot Injection Molding is {}. As a global leader in the manufacturing industry, {} has been at the forefront of developing and implementing this cutting-edge technology. With state-of-the-art facilities and a team of skilled engineers and technicians, {} has been able to push the boundaries of what is possible in the world of manufacturing.

The company's commitment to innovation and excellence has allowed them to perfect the Double Shot Injection Molding process, making it a core part of their manufacturing capabilities. By integrating this technology into their operations, {} has been able to produce a wide range of products that are not only durable and high-performing, but also visually striking and aesthetically pleasing.

With Double Shot Injection Molding, {} has been able to meet the demands of their customers in a variety of industries, from automotive and electronics to consumer goods and medical devices. The ability to create complex, multi-material parts in a single operation has allowed {} to streamline their production processes and deliver exceptional products to their clients in a timely manner.

One of the key advantages of Double Shot Injection Molding is its ability to reduce waste and minimize the environmental impact of manufacturing. By eliminating the need for additional assembly and bonding processes, this technology helps to reduce the amount of material and energy used in production. This not only benefits the company's bottom line, but also contributes to a more sustainable and eco-friendly manufacturing process.

Furthermore, Double Shot Injection Molding allows for greater design flexibility, as it opens up new possibilities for creating products with intricate and unique designs. This is particularly important in today's competitive market, where consumers are demanding products that not only perform well, but also stand out from the crowd. By leveraging the capabilities of Double Shot Injection Molding, {} has been able to differentiate themselves from their competitors and deliver products that exceed the expectations of their customers.

Looking ahead, the future of manufacturing is bright with the continued advancement of Double Shot Injection Molding. As technology continues to evolve, companies like {} will continue to push the boundaries of what is possible in the world of manufacturing. With their expertise and commitment to innovation, {} is well-positioned to lead the way in revolutionizing the industry and setting new standards for manufacturing efficiency and quality.

In conclusion, Double Shot Injection Molding is a game-changer for the manufacturing industry. With its ability to streamline production processes, reduce waste, and deliver high-quality, multi-material products, this innovative technology is paving the way for a more efficient and sustainable future. And with companies like {} leading the charge, the possibilities for what can be achieved with Double Shot Injection Molding are endless.

Company News & Blog

Durable and Affordable Multi-Purpose Crate Mould for Sale

Cheap Multi-Purpose Crate Mould Now Available at {}In today's competitive market, businesses are constantly looking for ways to reduce costs and improve efficiency. One way to achieve this is by investing in high-quality moulds for manufacturing various products.{}, a leading manufacturer of plastic injection moulds, is proud to announce the availability of its new multi-purpose crate mould at an affordable price. This new product is designed to help businesses improve their productivity and reduce overall production costs.The multi-purpose crate mould is a versatile tool that can be used to manufacture a wide range of products, including storage crates, pallets, and other containers. With its high precision and durability, this mould is capable of producing high-quality products that meet the industry's standards.One of the main advantages of this multi-purpose crate mould is its cost-effectiveness. By investing in a high-quality mould, businesses can reduce their production costs by improving efficiency and reducing waste. This can ultimately result in higher profits and a competitive edge in the market.In addition to its cost-effectiveness, this mould is also designed for ease of use and maintenance. Its durable construction ensures a long lifespan, reducing the need for frequent replacements and repairs. This means that businesses can rely on this mould for consistent performance and reliable production.Furthermore, the multi-purpose crate mould is compatible with a wide range of plastic materials, allowing businesses to choose the most suitable material for their specific needs. This flexibility makes it an ideal solution for businesses in various industries, from logistics and storage to manufacturing and distribution.With the introduction of this new product, {} continues to demonstrate its commitment to providing innovative solutions for businesses' manufacturing needs. As a leading manufacturer of plastic injection moulds, the company has a proven track record of delivering high-quality products that meet the industry's standards.{}, the founder and CEO of {}, expressed his excitement about the release of the multi-purpose crate mould. "We are dedicated to helping businesses improve their productivity and reduce their production costs. With our new mould, we aim to provide an affordable and reliable solution that meets the diverse needs of our customers," he said.The availability of the multi-purpose crate mould comes at a time when businesses are increasingly focused on finding ways to optimize their production processes. By investing in high-quality moulds, businesses can achieve significant cost savings and improve their overall competitiveness in the market.With its cost-effectiveness, versatility, and durability, the multi-purpose crate mould from {} is set to become a valuable asset for businesses looking to enhance their manufacturing capabilities.For businesses looking to invest in high-quality moulds at an affordable price, the multi-purpose crate mould from {} is certainly worth considering. With its proven performance and reliability, this mould is poised to help businesses achieve their production goals and stay ahead in today's competitive market. For more information, visit {} to learn more about the company’s products and services.

Discover the latest advancements in molding technology

Advanced Molding, a leading provider of high-quality plastic molding solutions, has recently made significant strides in their efforts to expand their operations and enhance their product offerings. With a focus on innovation and customer satisfaction, the company has solidified its position as a prominent player in the plastic molding industry.Founded in [year], Advanced Molding has established itself as a trusted partner for businesses seeking custom plastic molding solutions. With a state-of-the-art facility and a team of highly skilled engineers and technicians, the company has the capabilities to design and manufacture a wide range of plastic components for various industries, including automotive, medical, electronics, and consumer goods.Over the years, Advanced Molding has built a reputation for excellence in quality, precision, and reliability. Their commitment to utilizing the latest technology and industry best practices has enabled them to consistently deliver products that meet the highest standards. This dedication to excellence has earned the company the trust and loyalty of numerous clients, positioning them as a preferred supplier in the industry.One of the key factors driving the success of Advanced Molding is their continuous investment in research and development. The company is constantly exploring new materials, technologies, and processes to improve the efficiency and performance of their products. By staying at the forefront of innovation, Advanced Molding is able to offer cutting-edge solutions that meet the evolving needs of their customers.In line with their commitment to innovation, Advanced Molding recently completed the expansion of their production facilities. The new, state-of-the-art facility is equipped with the latest machinery and technology, allowing the company to increase its production capacity and improve operational efficiency. This expansion reflects the company's dedication to meeting the growing demand for their products and services.Furthermore, Advanced Molding has also broadened its product offerings to include a wider range of plastic molding solutions. In addition to their existing lineup of custom molding services, the company now provides tooling design, prototyping, and assembly services. This comprehensive approach allows them to offer end-to-end solutions to their clients, streamlining the manufacturing process and reducing time-to-market for new products.The company’s CEO, [Name], expressed his enthusiasm for the recent developments, stating, “We are thrilled to see the growth and expansion of our operations. It is a testament to the hard work and dedication of our team, as well as the trust and support of our valued customers. With our enhanced capabilities and expanded product offerings, we are well-positioned to continue serving the needs of our clients and further solidify our position as a leader in the plastic molding industry.”As Advanced Molding looks to the future, their focus remains on delivering exceptional quality, innovation, and customer satisfaction. With a strong foundation and a clear vision for growth, the company is poised to build on its success and make even greater strides in the industry.In conclusion, Advanced Molding has established itself as a premier provider of plastic molding solutions, driven by a commitment to excellence and innovation. With their recent expansion and enhanced product offerings, the company is well-equipped to meet the evolving needs of their customers and solidify their position as a leader in the industry. As they continue to push the boundaries of what is possible in plastic molding, Advanced Molding is poised for a future of continued success and industry leadership.

Top Medical Injection Molding Companies Facilitating Advanced Healthcare Solutions

Medical Injection Molding Companies Revolutionizing Healthcare Sector In recent years, the rapid advancement of medical injection molding technology has revolutionized the healthcare sector, improving patient care and transforming the way medical devices are manufactured. One notable player in this field is a leading medical injection molding company, which has been at the forefront of innovation and has established itself as a trusted partner in the medical device industry. With its high-quality products, cutting-edge technology, and dedication to meeting customer needs, this company has become a key player in shaping the future of healthcare.Founded over two decades ago, this medical injection molding company has grown from a small operation to a global leader in its field. The company's success lies in its commitment to producing superior medical devices that meet the highest industry standards. By leveraging advanced injection molding techniques, they are able to manufacture intricate and precise components that are crucial for the functioning of medical devices.One of the company's greatest strengths is its state-of-the-art manufacturing facilities. Equipped with the latest technology, including advanced robotics and computer-aided design (CAD) systems, these facilities enable the company to produce a wide range of medical devices with unprecedented precision and efficiency. Additionally, strict quality control measures are in place throughout the manufacturing process to ensure that each product meets the rigorous standards set by regulatory bodies.Another key aspect that sets this company apart is its emphasis on research and development (R&D). The company invests heavily in R&D to stay ahead of industry trends and develop innovative solutions in collaboration with its customers. By working closely with medical professionals and understanding their specific needs, they are able to design and manufacture products that address critical healthcare challenges.In recent years, a growing trend within the medical device industry has been the shift towards miniaturization. This is where the expertise of medical injection molding companies becomes indispensable. Through precise injection molding techniques, these companies are able to produce complex, miniature components that are essential for the development of smaller, portable medical devices. This advancement has allowed for greater patient convenience, increased portability, and improved overall patient experience.The medical injection molding company understands the importance of sustainability and environmental responsibility. It employs various eco-friendly practices throughout its operations, such as the use of bio-based materials and recycling programs. By minimizing waste and reducing its carbon footprint, the company demonstrates its commitment to a greener future.Furthermore, this company prioritizes customer satisfaction and aims to build long-term partnerships. With a team of experienced engineers and designers, they offer comprehensive support to their clients, from product design and development to manufacturing and distribution. By providing customized solutions and maintaining open lines of communication, they ensure that their customers' unique needs are met.In conclusion, medical injection molding companies have played a crucial role in transforming the healthcare sector by providing advanced, high-quality medical devices. This leading medical injection molding company, with its dedication to innovation and commitment to customer satisfaction, has emerged as a key player in the industry. Through its state-of-the-art manufacturing facilities, emphasis on R&D, and focus on sustainability, the company continues to shape the future of healthcare. As technology continues to advance, we can expect further advancements from this company and others in the field, driving the healthcare sector to new heights.

High-quality Plate Mould for Efficient Production

Plate Mould, a leading manufacturer of high-quality automotive and household moulds, has announced the launch of their latest product line. The company, which has been a trusted name in the industry for over 20 years, has built a strong reputation for producing durable and precise moulds for a wide range of applications.Plate Mould's state-of-the-art manufacturing facility is equipped with the latest technology and machinery, allowing them to produce moulds that meet the highest standards of quality and precision. Their team of experienced engineers and technicians work tirelessly to ensure that each mould is designed and manufactured to the exact specifications of their customers.The company's dedication to providing superior products and outstanding customer service has earned them a loyal customer base and a solid reputation within the industry. Their commitment to innovation and continuous improvement is evident in the performance and reliability of their moulds.Plate Mould's latest product line features a range of automotive and household moulds that have been carefully designed to meet the needs of their customers. From automotive parts to household appliances, the company's moulds are trusted by leading manufacturers and businesses around the world.In addition to their standard product line, Plate Mould also offers custom mould design and manufacturing services. Their experienced team works closely with customers to understand their specific requirements and develop moulds that meet their exact needs. Whether it's a unique automotive part or a custom household appliance, Plate Mould has the knowledge and expertise to bring their customers' visions to life.Plate Mould's commitment to quality and precision is evident in every aspect of their business. From the initial design phase to the final manufacturing process, the company takes great care to ensure that each mould meets their rigorous standards. This dedication to excellence has set them apart from their competitors and positioned them as a leader in the industry.With the launch of their latest product line, Plate Mould continues to demonstrate their commitment to innovation and quality. The new moulds are designed to provide superior performance and durability, allowing their customers to achieve excellent results in their manufacturing processes.Plate Mould's products are trusted by some of the biggest names in the automotive and household appliance industries, and their latest product line is expected to further solidify their position as a trusted provider of high-quality moulds. The company's dedication to excellence and customer satisfaction sets them apart from their competitors and reinforces their reputation as a leader in the industry.Plate Mould's latest product line is now available for purchase, and the company is excited to offer their customers access to their innovative and high-quality moulds. With their dedication to excellence and their commitment to customer satisfaction, Plate Mould continues to set the standard for quality and precision in the industry.

Guide to Preform Injection Molding: Everything You Need to Know

[Company Name], a leading manufacturer in the plastic molding industry, has recently announced the addition of Preform Injection Molding to its range of capabilities. This new injection molding technology will enable the company to meet the increasing demand for high-quality preforms in the packaging industry.Preform Injection Molding is a process that involves injecting molten material into a mold cavity, where it solidifies into the desired shape. This technology is commonly used in the production of PET (polyethylene terephthalate) preforms, which are a crucial component in the manufacturing of plastic bottles and containers.With the addition of Preform Injection Molding, [Company Name] will be able to offer a comprehensive solution to its customers, from design and prototyping to mass production. This new capability will allow the company to cater to a wider range of industries, including food and beverage, pharmaceuticals, and personal care.[Company Name] is known for its state-of-the-art facilities and advanced manufacturing techniques. The company utilizes the latest equipment and technologies to ensure the highest quality standards and efficiency in every aspect of production. With the introduction of Preform Injection Molding, [Company Name] further solidifies its position as an industry leader in plastics manufacturing.In addition to its technical capabilities, [Company Name] prides itself on its commitment to sustainability and environmental responsibility. The company has implemented various initiatives to reduce its environmental footprint, such as using eco-friendly materials and optimizing its manufacturing processes to minimize waste."We are thrilled to announce the addition of Preform Injection Molding to our list of capabilities," said [Spokesperson], [Title] at [Company Name]. "This new technology will not only enhance our offerings but also enable us to better serve our customers' needs, especially in the packaging industry. We are confident that this investment will further strengthen our position in the market and drive our continued growth."[Company Name] has continuously invested in research and development to stay ahead of industry trends and customer demands. The addition of Preform Injection Molding is a testament to the company's commitment to innovation and its dedication to providing cutting-edge solutions to its clients.As the demand for sustainable packaging solutions continues to rise, [Company Name] is well-positioned to address this market need with its new Preform Injection Molding capabilities. By leveraging this technology, the company will be able to produce preforms that are not only of the highest quality but also environmentally friendly.In conclusion, the addition of Preform Injection Molding to [Company Name]'s range of capabilities marks an exciting milestone for the company. With its focus on innovation, quality, and sustainability, [Company Name] is poised to set new standards in the plastics manufacturing industry and meet the evolving needs of its customers.About [Company Name][Company Name] is a leading manufacturer of plastic products, specializing in injection molding and precision engineering. With over [number] years of experience, the company is committed to delivering superior quality and innovative solutions to its clients. Headquartered in [Location], [Company Name] serves a diverse range of industries, including automotive, healthcare, consumer goods, and packaging. With a focus on sustainability and cutting-edge technology, [Company Name] continues to be a trusted partner for businesses seeking reliable and efficient plastic manufacturing solutions.

High-Quality Custom Plastic Parts for Your Business Needs

Custom Plastic Parts, a leading manufacturer in the plastic industry, has been making waves with their innovative and high-quality products. With a strong focus on customization and precision, the company has carved a niche for itself in the highly competitive market of plastic manufacturing. With a commitment to excellence and an unwavering dedication to customer satisfaction, Custom Plastic Parts has become a trusted name in the industry.Specializing in the production of custom plastic parts, the company offers a wide range of services including injection molding, 3D printing, and CNC machining. Their state-of-the-art facilities are equipped with the latest technology and machinery, allowing them to meet the diverse needs of their clients. Whether it's a small batch of specialized components or a large-scale production run, Custom Plastic Parts has the capability to deliver high-quality products with precision and efficiency.One of the key factors that sets Custom Plastic Parts apart from its competitors is their emphasis on customization. The company understands that every client has unique requirements and specifications, and they strive to provide tailor-made solutions that meet these individual needs. From the initial design phase to the final production, Custom Plastic Parts works closely with its clients to ensure that the end result is exactly what they envisioned.In addition to customization, the company places a strong emphasis on quality control and product testing. Every product that leaves their facility undergoes rigorous quality checks to ensure that it meets the highest standards of excellence. This commitment to quality has earned Custom Plastic Parts a reputation for reliability and consistency, further solidifying their position as a leader in the industry.Furthermore, Custom Plastic Parts is committed to sustainability and environmentally-friendly practices. The company recognizes the importance of minimizing its environmental impact and has implemented various initiatives to reduce waste and energy consumption. By utilizing eco-friendly materials and manufacturing processes, Custom Plastic Parts is taking proactive steps to contribute to a cleaner and greener planet.Recently, Custom Plastic Parts has been making headlines with their latest product offerings. The company has introduced a range of cutting-edge plastic parts that are designed to meet the ever-evolving needs of various industries. From automotive components to consumer electronics, Custom Plastic Parts has demonstrated its ability to adapt to the changing demands of the market and deliver innovative solutions that make a difference.In a statement regarding their latest products, the CEO of Custom Plastic Parts expressed his excitement about the company's achievements and the impact they are making in the industry. He emphasized the company's commitment to pushing the boundaries of innovation and delivering products that exceed the expectations of their clients. He also highlighted the dedication of the entire team at Custom Plastic Parts, whose hard work and expertise have been instrumental in the company's success.Looking ahead, Custom Plastic Parts has ambitious plans for the future. The company is actively investing in research and development to stay ahead of the curve and continue to offer cutting-edge solutions to their clients. With a strong focus on customer satisfaction and a relentless pursuit of excellence, Custom Plastic Parts is well-positioned to maintain its position as a leader in the plastic manufacturing industry.In conclusion, Custom Plastic Parts has established itself as a pioneering force in the plastic industry, with a strong emphasis on customization, quality, and innovation. With a commitment to sustainability and a customer-centric approach, the company continues to set new benchmarks for excellence. As they continue to push the boundaries of what is possible, Custom Plastic Parts is poised to remain at the forefront of the industry for years to come.

Understanding the Process and Benefits of Polypropylene Blow Molding

Polypropylene Blow Molding, often simply referred to as PP blow molding, is a manufacturing process that is widely used in the production of various plastic products. This versatile process allows for the creation of a wide range of products, including bottles, containers, and other hollow shapes.PP blow molding involves melting down plastic resin and then using air pressure to blow it into a mold. This process allows for the creation of products with thin walls, which can be especially advantageous when it comes to producing lightweight and cost-effective packaging solutions.One company that has become a leader in the field of PP blow molding is {}. They have established themselves as a key player in the industry, known for their high-quality products and innovative manufacturing techniques.{} is a leading manufacturer of PP blow molding products, with a deep commitment to meeting the needs of their customers. The company prides itself on its ability to offer custom solutions, tailored to the specific requirements of each client. Whether a customer needs packaging for a new product or is looking to improve the design of an existing container, {} has the expertise and capabilities to deliver.In addition to their dedication to customer satisfaction, {} is also highly focused on sustainability. They are aware of the impact that plastic products can have on the environment and are continuously working to reduce their carbon footprint. The company has invested in state-of-the-art technology and processes that allow them to minimize waste and energy consumption, while still delivering top-quality products.One of the key strengths of {} is their ability to collaborate closely with their clients. They understand that every project is unique and requires a tailored approach. By working closely with their customers, they are able to develop a deep understanding of their needs and provide the best possible solutions.{} has also distinguished themselves through their investment in research and development. They are always looking for new and innovative ways to improve their manufacturing processes, whether it's through the development of new materials or the implementation of cutting-edge technologies. This dedication to continuous improvement has positioned {} as a true industry leader.The company's production facilities are equipped with the latest machinery and technology, allowing them to produce a wide range of PP blow molding products with precision and efficiency. Their skilled team of engineers and technicians are dedicated to delivering products that meet the highest standards of quality.Recent advancements in PP blow molding technology have opened up new possibilities for product design and functionality. {} has been at the forefront of these developments, and they have been able to leverage this technology to offer their customers even more options and possibilities.In conclusion, PP blow molding is a highly versatile and efficient manufacturing process that is used for a wide variety of applications. Companies like {} are leading the way in this industry, providing high-quality, custom solutions for their clients. With a strong focus on customer satisfaction, sustainability, and innovation, {} is well-positioned to continue driving the evolution of the PP blow molding industry for years to come.

Top Molding Companies You Should Know About

Molding Companies are leading providers of high-quality plastic injection molding solutions for a wide range of industries. With state-of-the-art facilities and a team of highly skilled engineers and technicians, Molding Companies have built a solid reputation for delivering top-notch products and services to their clients.Molding Companies specialize in custom injection molding, offering a full suite of services including design, prototyping, tooling, and production. Their advanced manufacturing capabilities allow them to produce complex and intricate plastic parts with precision and efficiency, meeting the unique needs and specifications of their diverse customer base.One of the key differentiators of Molding Companies is their commitment to innovation and continuous improvement. They invest heavily in research and development to stay at the forefront of technological advancements in the plastic molding industry. This dedication to staying ahead of the curve enables Molding Companies to offer their clients cutting-edge solutions that are both cost-effective and sustainable.Furthermore, Molding Companies take a proactive approach to sustainability and environmental responsibility. They have implemented various eco-friendly practices in their manufacturing processes, such as using recycled materials, reducing energy consumption, and minimizing waste. By embracing sustainable manufacturing practices, Molding Companies not only contribute to environmental conservation but also help their clients meet their own sustainability goals.In addition to their technical expertise, Molding Companies are known for their unwavering commitment to customer satisfaction. They work closely with their clients to understand their specific requirements and provide tailored solutions that meet and exceed expectations. From initial concept to final production, Molding Companies are dedicated to delivering superior products and services that add value to their customers’ businesses.Molding Companies serve a diverse range of industries, including automotive, aerospace, medical, consumer goods, and electronics. Their extensive experience and knowledge in these sectors enable them to tackle complex projects and deliver results that meet the rigorous standards of each industry. Whether it’s producing intricate components for medical devices or manufacturing durable parts for automotive applications, Molding Companies have the expertise and capabilities to tackle any challenge.With a strong track record of success and a commitment to excellence, Molding Companies have earned the trust and loyalty of their clients. Their reputation for reliability, quality, and innovation has positioned them as a leading provider of plastic injection molding solutions in the industry. As they continue to expand their capabilities and stay at the forefront of technological advancements, Molding Companies are poised to meet the evolving needs of their clients and drive continued growth and success.With a strong focus on quality, innovation, and customer satisfaction, Molding Companies are well-equipped to serve the diverse needs of their clients across various industries. Their dedication to excellence and continuous improvement sets them apart as a premier provider of plastic injection molding solutions, and their commitment to sustainability underscores their responsibility as a global manufacturing leader. As they continue to push the boundaries of what’s possible in plastic molding, Molding Companies are positioned for long-term success and growth as a trusted partner for their clients.

Expert Tips for Maintaining and Repairing Your Car Molds

Auto Mold Company: A Leading Supplier in the Automotive IndustryAuto Mold Company is a well-established supplier of automotive molds and components to the global automotive industry. With a strong reputation for delivering high-quality, innovative products, the company has become a trusted partner for major automotive manufacturers and suppliers around the world.The company was founded in 1995 and has since grown to become a leading provider of automotive molds and components for a wide range of vehicles, from passenger cars to commercial vehicles. With state-of-the-art facilities and a highly skilled workforce, Auto Mold Company is dedicated to providing its customers with the latest technologies and the highest quality products.Auto Mold Company offers a wide range of services, including mold design, mold manufacturing, and plastic injection molding. The company's expertise in these areas allows it to provide its customers with comprehensive solutions for their automotive mold and component needs.In addition to its comprehensive range of services, Auto Mold Company is committed to continuous innovation and improvement. The company invests heavily in research and development to stay at the forefront of automotive mold technology and to ensure that its products meet the highest industry standards.One of the company's key strengths is its ability to work closely with its customers to develop customized solutions that meet their specific needs. Auto Mold Company's team of engineers and designers are highly experienced in collaborating with customers to develop innovative and efficient mold and component designs.Auto Mold Company's commitment to quality and customer satisfaction has earned it a strong reputation in the automotive industry. The company has been recognized with numerous awards for excellence in manufacturing and has received praise from its customers for its reliability and dedication to delivering high-quality products.Recently, Auto Mold Company announced the launch of its latest innovative mold design, the XYZ Mold. This new mold design incorporates the latest technologies and materials to provide customers with a more efficient and cost-effective solution for their mold and component needs. The XYZ Mold is designed to improve productivity and reduce manufacturing costs, making it an ideal choice for automotive manufacturers and suppliers.The launch of the XYZ Mold highlights Auto Mold Company's dedication to staying at the forefront of automotive mold technology and its commitment to providing its customers with the latest and most innovative solutions. The company's investment in research and development has enabled it to develop this cutting-edge mold design, which is set to revolutionize the automotive mold and component industry.Auto Mold Company's CEO, John Smith, commented on the launch of the XYZ Mold, saying, "We are thrilled to introduce the XYZ Mold to the market. This innovative mold design is the result of our ongoing commitment to research and development and our dedication to providing our customers with the best solutions for their mold and component needs. We believe that the XYZ Mold will set a new standard in the automotive mold industry and will further solidify Auto Mold Company's position as a leader in the market."As a leading supplier of automotive molds and components, Auto Mold Company continues to demonstrate its commitment to excellence and innovation. With its comprehensive range of services, dedication to quality, and ongoing investment in research and development, the company is well-positioned to maintain its strong reputation and to provide its customers with the best solutions for their automotive mold and component needs.

High-Quality Automatic Pet Blowing Machine Available Now

Automatic Pet Blowing Machine Revolutionizes Pet Bottle Manufacturing{Company}, a leading manufacturer of high-quality packaging machinery, has recently introduced a state-of-the-art Automatic Pet Blowing Machine that promises to revolutionize the pet bottle manufacturing industry. With the increasing demand for pet bottles across various industries, this innovative machine is set to streamline the production process, increase efficiency, and ensure superior product quality.The Automatic Pet Blowing Machine is equipped with advanced technology and features that set it apart from traditional pet blowing machines. Its fully automatic operation eliminates the need for manual intervention, reducing the chances of human error and ensuring consistent production output. This not only increases the efficiency of the manufacturing process but also results in significant cost savings for companies in the long run.Furthermore, the machine's high-speed production capabilities make it ideal for meeting the growing demand for pet bottles in the beverage, pharmaceutical, and personal care industries. Its ability to produce a wide range of bottle sizes and shapes provides companies with the flexibility to cater to diverse customer requirements, giving them a competitive edge in the market.In addition to its impressive production capabilities, the Automatic Pet Blowing Machine also prioritizes product quality and safety. Its advanced design and precision engineering ensure that each pet bottle produced is uniform in shape, thickness, and durability. This not only enhances the visual appeal of the bottles but also ensures that they meet the highest standards of quality and safety for consumer use.{Company} has always been at the forefront of innovation in the packaging machinery industry, and the introduction of the Automatic Pet Blowing Machine is a testament to its commitment to delivering cutting-edge solutions to its customers. With a proven track record of providing reliable and efficient machinery, the company has established itself as a trusted partner for businesses looking to optimize their production processes and stay ahead of the competition.The Automatic Pet Blowing Machine is designed to integrate seamlessly into existing manufacturing setups, making it a cost-effective investment for companies looking to upgrade their pet bottle production capabilities. Its user-friendly interface and intuitive controls make it easy to operate and maintain, minimizing downtime and maximizing productivity.Furthermore, {Company} offers comprehensive support and maintenance services for the Automatic Pet Blowing Machine, ensuring that customers can rely on uninterrupted production and peak performance at all times. This commitment to customer satisfaction sets {Company} apart as a reliable and responsive partner in the packaging machinery industry.The introduction of the Automatic Pet Blowing Machine comes at a time when the demand for pet bottles is soaring globally, driven by the increasing consumption of beverages, personal care products, and pharmaceuticals. As companies strive to meet this demand while maintaining high standards of quality and efficiency, the Automatic Pet Blowing Machine emerges as a game-changing solution that addresses these key challenges effectively.In conclusion, the Automatic Pet Blowing Machine from {Company} represents a significant advancement in pet bottle manufacturing technology, offering a combination of precision engineering, high-speed production, and exceptional product quality. With its potential to transform the way pet bottles are produced, this innovative machine is poised to make a lasting impact on the packaging industry and empower businesses to thrive in a competitive market.