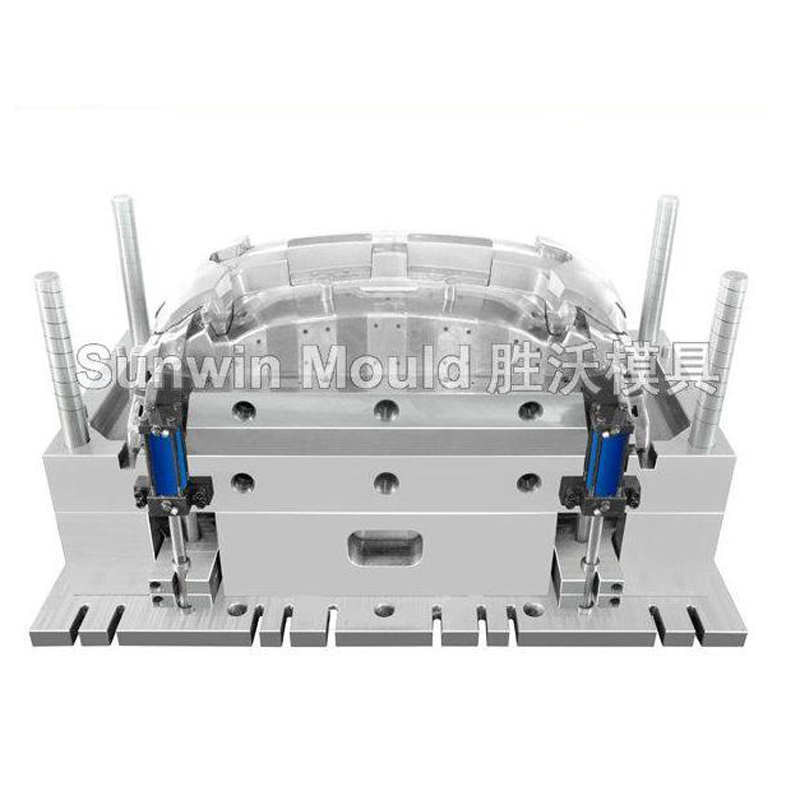

High-Quality Custom Injection Molding Services for Plastic Products

By:Admin

One company leading the way in Custom Plastic Injection Molding is {}. With over 20 years of experience, {} has established itself as a premier provider of custom plastic solutions for a wide range of industries including automotive, aerospace, electronics, medical, and consumer goods.

The company's state-of-the-art facilities are equipped with the latest in injection molding technology, allowing them to produce complex and precise plastic parts with efficiency and accuracy. Their team of experienced engineers and technicians work closely with clients to develop custom mold designs and manufacturing processes that meet their specific needs and requirements.

{} has a strong focus on quality control and assurance, ensuring that every product that comes out of their facility meets the highest standards of durability, functionality, and aesthetics. Their rigorous quality control processes and inspection protocols guarantee that all products are free from defects and imperfections, giving clients the confidence that their end products will perform as intended.

The company's commitment to sustainability is also evident in their manufacturing processes. They utilize environmentally friendly materials and practices to minimize waste and reduce their carbon footprint. By implementing efficient manufacturing techniques and utilizing eco-friendly materials, they are able to produce high-quality plastic products while minimizing their impact on the environment.

In addition to their expertise in Custom Plastic Injection Molding, {} also offers a range of value-added services including prototype development, mold design and engineering, and secondary operations such as assembly, packaging, and distribution. Their comprehensive approach to product development and manufacturing allows them to provide clients with a complete solution from concept to final production.

The company's reputation for excellence and customer satisfaction has earned them the trust of clients both locally and internationally. Their dedication to delivering innovative solutions and outstanding customer service has solidified their position as a leader in the custom plastic injection molding industry.

With a proven track record of success and a commitment to continuous improvement, {} is poised to continue its growth and expansion in the custom plastic manufacturing sector. Their ability to adapt to the changing needs of the market and deliver superior products and services makes them a valuable partner for businesses looking for reliable and cost-effective plastic injection molding solutions.

As the demand for custom plastic products continues to rise, {} remains at the forefront of the industry, providing innovative and sustainable solutions that meet the evolving needs of their clients. Their investment in advanced technology, talented workforce, and commitment to excellence positions them as a top choice for businesses seeking custom plastic injection molding services.

In conclusion, the future looks bright for {} as they continue to expand their capabilities and maintain their commitment to delivering exceptional custom plastic solutions. With a focus on innovation, sustainability, and customer satisfaction, they are well-positioned to lead the way in the custom plastic injection molding industry for years to come.

Company News & Blog

New technology in the Pet Preform Blowing Machine industry revolutionizes production process

Pet Preform Blowing Machine has revolutionized the way pet preforms are manufactured. This advanced machine uses the latest technology to produce high-quality pet preforms that are used in the production of PET bottles for a variety of products including water, soda, juice, and more. The machine is designed to be efficient, reliable, and easy to use, making it a valuable asset for companies in the beverage and packaging industries.The company behind this innovative machine is a leading manufacturer of packaging machinery with a commitment to providing top-quality equipment for their clients. With a strong focus on research and development, the company is constantly striving to improve their products and stay ahead of industry trends. Their dedication to excellence has earned them a reputation for delivering reliable and high-performance machinery that meets the needs of their customers.The Pet Preform Blowing Machine is a prime example of the company's commitment to innovation. It is designed to streamline the production process, reducing the time and labor required to manufacture pet preforms. The machine is capable of producing a wide range of preform sizes and shapes, allowing for greater flexibility in bottle design and production. This versatility is a major advantage for companies looking to stay competitive in the ever-evolving beverage market.In addition to its advanced technology, the Pet Preform Blowing Machine is also designed with user-friendly features that make it easy to operate and maintain. This includes an intuitive control panel and a modular design that allows for easy access to key components for maintenance and repairs. The machine is also equipped with safety features to ensure the protection of operators and prevent accidents in the workplace.The company's dedication to customer satisfaction is evident in their comprehensive customer support services. They provide training and technical assistance for customers who purchase their machinery, ensuring that operators are well-equipped to maximize the efficiency and performance of the Pet Preform Blowing Machine. Furthermore, they offer prompt and reliable after-sales service, including spare parts and maintenance services to keep their machines running smoothly for years to come.As sustainability becomes an increasingly important factor in the packaging industry, the Pet Preform Blowing Machine is also designed with energy efficiency in mind. It is engineered to minimize energy consumption without sacrificing production output, making it an environmentally responsible choice for companies seeking to reduce their carbon footprint.Overall, the Pet Preform Blowing Machine is a valuable asset for companies in the beverage and packaging industries. Its advanced technology, user-friendly features, and commitment to sustainability make it a reliable and efficient solution for the production of high-quality pet preforms. With the backing of a reputable and customer-focused company, this machine is set to make a significant impact on the industry and help companies stay ahead of the competition.

High-Quality Box Mould for Resin: Everything You Need to Know

**Company Introduction**[Company Name] is a leading manufacturer of high-quality moulds for various industrial applications. With years of experience and expertise in the field, we have been providing innovative solutions for our customers, helping them achieve their production goals with efficiency and precision.Our commitment to quality and customer satisfaction has made us a trusted partner for businesses across different industries. We continuously invest in research and development to stay ahead of industry trends and deliver cutting-edge products that meet the evolving needs of our clients.**News Content: Box Mould For Resin**[Company Name] has recently introduced a groundbreaking box mould for resin, designed to revolutionize the resin manufacturing process. This innovative mould is set to bring significant improvements in efficiency and product quality for resin manufacturers, setting a new standard in the industry.The box mould for resin is engineered with precision and attention to detail, taking into account the specific requirements of resin production. Its design features are tailored to optimize the production process and minimize waste, resulting in cost savings and increased productivity for manufacturers.One of the key highlights of this box mould is its durability and longevity. Made with high-quality materials and advanced manufacturing techniques, the mould is built to withstand the rigors of resin production, providing a reliable and long-lasting solution for manufacturers.In addition to its robust construction, the box mould for resin also incorporates advanced molding technology, ensuring consistent and accurate shaping of resin products. This level of precision is essential in meeting quality standards and delivering products that meet the exact specifications of customers.Furthermore, the design of the mould allows for easy handling and maintenance, streamlining the production workflow and reducing the downtime associated with mold servicing. This feature significantly contributes to operational efficiency and overall cost-effectiveness for resin manufacturers.The introduction of this innovative box mould for resin reflects [Company Name]'s commitment to driving progress and innovation in the industry. By providing manufacturers with cutting-edge solutions, we aim to empower businesses to achieve their production goals with superior quality and efficiency.Moreover, the box mould for resin aligns with our company's overarching mission to deliver exceptional value to our customers. We recognize the challenges and demands of modern manufacturing, and through our innovative products, we strive to support businesses in overcoming these obstacles and excelling in their respective markets.As we continue to expand our product offerings and push the boundaries of technological advancement, we remain dedicated to upholding the highest standards of quality and reliability. Our goal is to be the preferred partner for businesses seeking innovative mould solutions that drive their success and elevate their competitiveness.In conclusion, the introduction of the box mould for resin is a significant milestone for [Company Name] and the resin manufacturing industry as a whole. With its unparalleled quality, advanced features, and potential for enhancing production capabilities, this innovative mould is set to make a lasting impact on the industry, cementing [Company Name]'s reputation as a trailblazer in industrial mould manufacturing.

Growing Demand and Opportunities in the Injection Molding Industry Revealed by Latest News

[News Title]Injection Molding Industry Experiences Robust Growth Amid Technological Advancements[News Content]The injection molding industry has witnessed tremendous growth in recent years, thanks to the continuous advancements in technology. With the ability to produce complex and intricate parts with high precision and efficiency, injection molding has become a cornerstone in various sectors, ranging from automotive and packaging to electronics and healthcare.One of the leading players in this industry is a renowned company () that has been at the forefront of manufacturing top-quality injection molding machines. With its commitment to innovation and customer satisfaction, the company has revolutionized the industry and has played a pivotal role in its expansion.Established over two decades ago, () has carved a niche for itself by providing state-of-the-art injection molding machines tailored to meet diverse customer needs. Their machines offer exceptional durability and reliability while providing excellent performance and productivity. () has earned a stellar reputation for delivering top-notch products and exceptional customer service.Furthermore, the company's dedication to research and development has empowered them to continuously enhance their machinery's capabilities. By investing in the latest technologies and incorporating advanced features, () has been able to offer cutting-edge solutions that meet the ever-evolving demands of the injection molding industry.The injection molding industry has seen a surge in demand due to its ability to manufacture complex components with precision, reduce production costs, and streamline processes. () has played a critical role in this growth by providing manufacturers with high-quality and efficient machinery that ensures accurate and consistent production.The automotive industry has been a significant contributor to the expansion of the injection molding sector. With the growing demand for lightweight and eco-friendly vehicles, manufacturers are increasingly relying on injection molding techniques to produce various interior and exterior components. The machines provided by () have been instrumental in helping automotive manufacturers meet these demands, thanks to their precision, speed, and energy efficiency.Moreover, the packaging industry has also experienced a boost from the injection molding advancements. The ability to manufacture intricate and customized packaging solutions has bolstered the growth of this sector. Companies in the packaging industry are now able to produce durable, lightweight, and appealing packaging solutions using injection molding techniques. ()'s machines have played a vital role in enhancing the productivity and efficiency of packaging manufacturers, enabling them to cater to the evolving consumer preferences.The electronics industry has also relied heavily on injection molding to produce intricate and precise components required for various electronic devices. The miniaturization of electronic devices has necessitated the production of smaller and more intricate parts, making injection molding a preferred choice. () has provided manufacturers in the electronics industry with machines capable of producing high-precision components efficiently, creating a positive impact on their production capabilities.Furthermore, the healthcare sector has benefited immensely from injection molding techniques. The ability to produce sterile and high-quality medical devices and equipment has improved patient care and safety. ()'s state-of-the-art injection molding machines have been pivotal in facilitating the production of medical components while adhering to stringent quality control measures.The growing demand for quality goods coupled with the continuous advancements in the injection molding industry has positioned () as a leading player in the global market. With strong customer focus, technological expertise, and a commitment to innovation, () is set to empower manufacturers in different industries to achieve their production goals efficiently and sustainably.In conclusion, the injection molding industry is experiencing significant growth due to the continuous advancements in technology. Companies like () have played a vital role in revolutionizing the industry by providing innovative and high-quality machinery. With the ability to produce complex and precise components, injection molding has become an integral part of various sectors, including automotive, packaging, electronics, and healthcare. ()'s commitment to research and development, along with their exceptional customer service, has solidified their position as a prominent player in the global injection molding market.

How to Find the Best Plastic Bucket Mold

Plastic Bucket Mold: Enhancing Sustainable ManufacturingIn the world of manufacturing, sustainability has become an increasingly important consideration. With growing concerns about environmental impact and the need for more eco-friendly processes, companies are seeking innovative solutions to minimize their carbon footprint. One such solution is the development of plastic bucket molds that not only optimize production efficiency but also promote sustainability. One company that has been at the forefront of this movement is ***. With a solid reputation in the manufacturing industry, *** has been dedicated to producing high-quality plastic bucket molds that are not only durable and efficient but also environmentally friendly. By incorporating innovative design and cutting-edge technology, *** has revolutionized the production of plastic buckets, paving the way for a more sustainable approach to manufacturing.The plastic bucket molds developed by *** are designed to meet the diverse needs of the industry. Whether for industrial, commercial, or domestic use, these molds are engineered to produce buckets that are durable, reliable, and cost-effective. By using advanced materials and precision engineering, *** has been able to create molds that ensure the highest level of quality and consistency in each bucket produced. This not only reduces waste but also contributes to a more sustainable manufacturing process.Furthermore, *** has also prioritized environmentally friendly practices in their production process. By implementing energy-efficient technologies and recycling initiatives, *** has significantly reduced its environmental impact. The company has also made a conscious effort to minimize the use of harmful chemicals and utilize sustainable materials in the production of their molds. This commitment to sustainability has earned *** recognition as a leader in eco-friendly manufacturing practices.In addition to their dedication to sustainability, *** has also excelled in providing exceptional customer service. With a team of highly skilled professionals, the company offers comprehensive support to its clients, from initial design and development to production and maintenance. By understanding the unique needs of each client, *** ensures that the plastic bucket molds they provide are customized to meet specific requirements. This personalized approach has helped *** build long-term relationships with clients and establish itself as a trusted partner in the industry.As part of their continuous improvement efforts, *** has also invested in research and development to stay ahead of the curve in the manufacturing industry. By staying abreast of the latest technological advancements and market trends, the company continuously enhances its products to meet the evolving needs of its clients. This dedication to innovation has allowed *** to consistently deliver cutting-edge plastic bucket molds that set new standards in the industry.Looking ahead, *** remains committed to pushing the boundaries of sustainable manufacturing. The company continues to explore new technologies and design methodologies that further reduce environmental impact and enhance production efficiency. With a focus on sustainability, innovation, and customer satisfaction, *** is poised to remain a driving force in the manufacturing of plastic bucket molds.In conclusion, the development of plastic bucket molds by *** has not only revolutionized the manufacturing process but has also set a new standard for sustainability in the industry. By combining advanced technology, eco-friendly practices, and exceptional customer service, *** has established itself as a leading provider of high-quality, sustainable plastic bucket molds. With a continued commitment to innovation and sustainability, *** is driving positive change in the manufacturing industry and setting an example for others to follow.

Everything You Need to Know About Thermoplastic Molding

Thermoplastic Molding has been making waves in the manufacturing industry, and one company that has been at the forefront of this innovative technology is {}. {} is a leading manufacturer that specializes in thermoplastic molding, offering high-quality products and services for a wide range of industries. With a strong emphasis on research and development, they have been able to stay ahead of the curve and provide their customers with cutting-edge solutions for their manufacturing needs.One of the key advantages of thermoplastic molding is its ability to produce complex and intricate parts with great precision and efficiency. This makes it an ideal choice for industries such as automotive, aerospace, medical devices, and consumer goods. With advancements in technology, thermoplastic molding has become more versatile and cost-effective, opening up new possibilities for manufacturers.{} has capitalized on this trend by investing in state-of-the-art equipment and training their staff to be experts in thermoplastic molding techniques. With a combination of high-tech machinery and skilled personnel, they are able to offer a wide range of customized solutions to meet the specific needs of their clients.In addition to their expertise in thermoplastic molding, {} prides itself on its commitment to sustainability and environmental responsibility. They have implemented eco-friendly practices in their manufacturing processes to minimize waste and reduce their carbon footprint. This has made them a preferred partner for companies that are looking to promote sustainability in their supply chain.Furthermore, {} places a strong emphasis on quality control and consistency in their products. They have stringent testing procedures in place to ensure that every part meets the highest standards of performance and reliability. This has earned them a solid reputation in the industry as a reliable and trustworthy supplier.With the ongoing advancements in thermoplastic molding technology, {} is well-positioned to capitalize on the growing demand for high-quality plastic parts. They have a dedicated team of engineers and designers who are constantly exploring new ways to improve their processes and develop innovative solutions for their clients.As a testament to their expertise in thermoplastic molding, {} has received various accolades and certifications for their outstanding performance in the industry. This includes recognition for their commitment to quality, innovation, and customer satisfaction. These achievements have helped to solidify their position as a leader in the field of thermoplastic molding.Looking ahead, {} is poised for further growth and expansion as they continue to invest in research and development and expand their capabilities. With a strong focus on customer satisfaction and technological innovation, they are well-equipped to meet the evolving needs of the manufacturing industry and remain a trusted partner for their clients.In conclusion, thermoplastic molding is a game-changer in the manufacturing industry, and {} has established itself as a leader in this field. With their expertise, commitment to quality, and dedication to innovation, they are well-positioned to thrive in an increasingly competitive market. As they continue to push the boundaries of what is possible with thermoplastic molding, they will undoubtedly remain a powerhouse in the industry for years to come.

How to Choose the Best Plastic Mold Maker for Your Project

Plastic Mold Maker Expands Operations to Meet Growing DemandAs the demand for high-quality plastic molds continues to rise, leading plastic mold maker, (brand name removed), is expanding its operations to meet the growing needs of its customers. With a strong focus on precision and innovation, the company is dedicated to providing top-notch plastic molding solutions for a wide range of industries, including automotive, consumer products, medical devices, and more.The company's expansion comes as a response to the increasing demand for custom plastic molds, driven by the need for specialized and intricate components in various manufacturing processes. With a commitment to staying at the forefront of technology and design, (brand name removed) has invested in state-of-the-art equipment and advanced manufacturing techniques to ensure the highest level of quality and accuracy in its plastic molds.In addition to its cutting-edge technology, (brand name removed) prides itself on its team of highly skilled and experienced mold makers, engineers, and designers who work diligently to bring customers' concepts to life. The company's dedication to collaboration and excellence has earned it a strong reputation in the industry, as well as a loyal customer base that values its expertise and commitment to delivering exceptional results.With the expansion of its operations, (brand name removed) is poised to increase its production capacity and offer even more comprehensive solutions to meet the evolving needs of its customers. The company's new facility will house additional manufacturing equipment and resources, allowing it to take on a wider range of projects and deliver molds with even greater efficiency and precision.The expansion also reflects (brand name removed)'s dedication to providing a seamless and reliable experience for its customers. By streamlining its operations and increasing its capabilities, the company aims to further solidify its position as a trusted partner for businesses seeking top-tier plastic molding solutions.Furthermore, (brand name removed) is committed to sustainability and environmental responsibility in its operations. The company has implemented eco-friendly practices and materials in its manufacturing processes, ensuring that its products have minimal impact on the environment. With a focus on efficiency and reducing waste, (brand name removed) strives to be a leader in sustainable plastic mold manufacturing.As part of its expansion, (brand name removed) continues to invest in research and development, exploring new materials and processes to further enhance its product offerings. By staying at the forefront of industry trends and advancements, the company is well-positioned to meet the evolving needs of its customers and provide them with the latest innovations in plastic mold technology.In conclusion, (brand name removed)'s expansion is a testament to its unwavering commitment to excellence and customer satisfaction. With its advanced technology, skilled team, and dedication to sustainability, the company is poised to continue leading the way in providing top-quality plastic molding solutions for a wide range of industries. As the demand for custom plastic molds continues to grow, (brand name removed) is well-prepared to meet the needs of its customers and deliver outstanding results.

Expert Tips for Flashing Plastic Moulding

Flashing Plastic Moulding, a leading manufacturer of high-quality plastic molds and components, has rapidly become a key player in the plastic moulding industry. The company has built a solid reputation for producing top-notch plastic moulding products and has won the trust of many clients around the world.Based in {location}, Flashing Plastic Moulding has been serving a wide range of industries, including automotive, electronics, medical, and consumer goods. The company's state-of-the-art manufacturing facilities and cutting-edge technology enable it to produce custom plastic moulding solutions that meet the specific needs of its clients.Flashing Plastic Moulding's commitment to quality and precision has set it apart in the industry. The company's team of highly skilled engineers and technicians work tirelessly to ensure that every plastic moulding product meets the highest standards and exceeds client expectations. This dedication to excellence has earned Flashing Plastic Moulding a solid reputation for delivering superior products and exceptional service.One of the key factors contributing to Flashing Plastic Moulding's success is its ability to provide custom plastic moulding solutions. The company works closely with its clients to understand their unique requirements and develop tailored solutions that meet their specific needs. Whether it's a complex automotive component or a precision medical device, Flashing Plastic Moulding has the expertise and capabilities to deliver custom plastic moulding products that are second to none.In addition to custom plastic moulding solutions, Flashing Plastic Moulding also offers a wide range of standard plastic moulding products. From injection molded components to extruded profiles, the company's extensive product portfolio caters to a diverse range of applications and industries. Flashing Plastic Moulding's dedication to innovation and continuous improvement ensures that its product offerings remain at the forefront of the industry.Flashing Plastic Moulding also places a strong emphasis on sustainability and environmental responsibility. The company is committed to reducing its environmental footprint and minimizing waste throughout the manufacturing process. By utilizing eco-friendly materials and implementing efficient production practices, Flashing Plastic Moulding strives to minimize its impact on the environment while delivering top-quality plastic moulding products.Furthermore, Flashing Plastic Moulding is constantly investing in research and development to stay ahead of the curve in the plastic moulding industry. The company continuously explores new materials, technologies, and processes to enhance its capabilities and deliver innovative solutions to its clients. This proactive approach to innovation has allowed Flashing Plastic Moulding to remain a leader in the industry and continue to push the boundaries of plastic moulding technology.As Flashing Plastic Moulding continues to grow and expand its presence in the global market, the company remains committed to upholding its core values of quality, innovation, and customer satisfaction. With a strong focus on excellence and a dedication to meeting the unique needs of its clients, Flashing Plastic Moulding is well-positioned to continue its success in the plastic moulding industry for years to come. Whether it's a custom plastic moulding solution or a standard plastic moulding product, clients can trust Flashing Plastic Moulding to deliver outstanding quality and service.

Leading Chinese Car Exterior Door Trim Factory Offers Quality Products

China's Leading Car Exterior Door Trim Factory Revolutionizes Automotive IndustryIn a major stride towards innovation in the automotive industry, China's prominent car exterior door trim factory has introduced cutting-edge technology and manufacturing processes. With a steadfast commitment to quality, precision, and customer satisfaction, this leading factory aims to reshape the car door trim market domestically and internationally.Established with a vision to cater to the burgeoning automotive market in China and beyond, the factory has rapidly gained recognition as a trusted manufacturer of car exterior door trim. By integrating advanced machinery, specialized tools, and high-quality materials, the factory ensures the production of superior door trim products that enhance both the aesthetics and functionality of vehicles.One of the key factors contributing to the factory's success is their relentless pursuit of innovation. By consistently investing in research and development, they have stayed abreast of the latest industry trends and technological advancements. This approach has enabled them to develop and manufacture door trim products that surpass customer expectations in terms of durability, design, and functionality.Moreover, the factory's commitment to quality control is unwavering. Every stage of production undergoes strict scrutiny, from material selection to the final inspection. This meticulous attention to detail ensures that each car exterior door trim leaving the factory is of the highest standards, meeting or exceeding global quality benchmarks.The factory boasts state-of-the-art facilities that utilize the most advanced manufacturing techniques. Equipped with cutting-edge robotics, computer numerical control (CNC) machines, and automated systems, the factory maximizes efficiency and accuracy in the production process. These technologies allow for precise customization of door trim components, catering to the diverse needs and specifications of various car models.Furthermore, the factory places great importance on environmental sustainability. Recognizing the global shift towards eco-friendly practices, they have implemented energy-efficient processes and eliminated harmful emissions. By adhering to stringent environmental regulations, they ensure that their manufacturing practices align with worldwide sustainability standards.To maintain their leading position in the market, the factory prioritizes continuous improvement. They actively engage with industry experts, collaborate with renowned design firms, and invest in training programs for their staff. These initiatives nurture innovation, foster creativity, and enhance the factory's overall competitiveness in the automotive industry.As a result of their unwavering dedication to cutting-edge technology, quality control, efficiency, and sustainability, the factory has earned the trust of numerous domestic and international automobile manufacturers. Their car exterior door trim products have become the go-to choice for industry giants, catering to a wide range of vehicle models that vary in size, style, and function.Looking towards the future, the factory intends to further diversify its product range. By expanding their manufacturing capabilities and incorporating advanced materials, they aim to introduce revolutionary door trim solutions. Anticipating the rise of electric vehicles, they are also investing in research and development to create innovative door trim designs that align with the unique requirements of this growing sector.With their commitment to excellence, reliability, and customer satisfaction, China's leading car exterior door trim factory is poised to transform the automotive industry. Their continuous pursuit of innovation and dedication to quality ensure that both domestic and international customers will experience the epitome of product perfection when choosing their car exterior door trim.

Top-quality Blow Molding Mold for Efficient Production

[Company Logo][Company Name] Introduces New Blow Molding Mold for Enhanced Production Efficiency[City, State] - [Date][Company Name], a leading provider of innovative packaging solutions, is pleased to announce the launch of its latest blow molding mold designed to enhance production efficiency in the manufacturing industry. With a focus on delivering high-quality, cost-effective solutions, [Company Name] continues to innovate and lead the way in the packaging industry.Blow molding is a manufacturing process used to create hollow plastic parts, such as bottles and containers. It is a versatile and cost-effective method for producing a wide range of products. The quality and efficiency of blow molding are highly dependent on the design and performance of the mold used in the process.The new blow molding mold introduced by [Company Name] is the result of extensive research and development, aimed at addressing the challenges faced by manufacturers in the industry. The mold features a cutting-edge design that ensures consistent product quality and greater production efficiency."We are excited to unveil our new blow molding mold, which is the culmination of our commitment to delivering innovative solutions to our customers," said [Spokesperson's Name], [Title] at [Company Name]. "We understand the challenges faced by manufacturers in today's competitive market, and our goal is to provide them with tools that can help them improve their production processes and stay ahead of the curve."The new blow molding mold from [Company Name] offers several key benefits that set it apart from traditional molds. Its advanced design allows for faster cycle times, leading to increased production output without compromising on product quality. Additionally, the mold is engineered to optimize material distribution, resulting in reduced waste and improved overall efficiency.In line with [Company Name]'s commitment to sustainability, the new blow molding mold is also designed to minimize energy consumption during the manufacturing process. By incorporating advanced technology and engineering expertise, the mold contributes to a more sustainable and eco-friendly production environment."We believe that innovation and sustainability go hand in hand, and our new blow molding mold is a testament to that belief," [Spokesperson's Name] continued. "It is our mission to help our customers achieve their production goals while minimizing their environmental impact, and this new mold is a step in that direction."The introduction of the new blow molding mold underscores [Company Name]'s dedication to staying at the forefront of the packaging industry. With a track record of delivering reliable and cost-effective solutions to its customers, the company is well-positioned to make a significant impact with its latest innovation."We are confident that our new blow molding mold will bring tangible benefits to manufacturers looking to enhance their production capabilities," said [Spokesperson's Name]. "By leveraging our expertise and industry knowledge, we have developed a solution that addresses the evolving needs of the market and sets a new standard for blow molding technology."As part of its commitment to customer satisfaction, [Company Name] will provide comprehensive support and guidance to help manufacturers integrate the new blow molding mold into their production processes seamlessly. The company's team of experts is readily available to assist with any technical inquiries and provide assistance in optimizing the mold for specific production requirements.The new blow molding mold from [Company Name] is now available for purchase, and the company is already receiving positive feedback from early adopters. With its focus on innovation, quality, and customer support, [Company Name] is poised to make a significant impact on the blow molding industry with its latest offering.For more information about the new blow molding mold and other innovative packaging solutions from [Company Name], please visit [company website] or contact [contact information].[Company Logo]Contact:[Company Name][Contact Person][Address][Phone][Email][Website]

High-Efficiency Blow Molding Machine: Latest Advancements in Bottle Manufacturing Technology

The Bottle Blow Molding Machine market is witnessing significant growth with the rising demand for plastic bottles across various industries such as food and beverages, pharmaceuticals, and personal care products. The need for efficient and high-speed manufacturing processes has led to the increased adoption of bottle blow molding machines, which are capable of producing a large number of bottles in a short period of time.One of the leading players in the bottle blow molding machine industry is {}. With over 20 years of experience in manufacturing and supplying blow molding machines, {} has established itself as a reliable and innovative company in the market. The company is known for its high-quality machines that are durable, efficient, and capable of meeting the diverse needs of its customers.{} offers a wide range of bottle blow molding machines, including fully automatic, semi-automatic, and stretch blow molding machines. These machines are designed to produce various types of bottles, such as PET bottles, HDPE bottles, and PP bottles, with different shapes and sizes. The company's machines are equipped with advanced technology and features that ensure high precision, consistency, and productivity in the bottle manufacturing process.One of the key strengths of {} is its commitment to continuous innovation and improvement in its product offerings. The company invests heavily in research and development to enhance its machine designs, optimize production processes, and incorporate new technologies to stay ahead of market trends. This dedication to innovation has enabled {} to provide its customers with state-of-the-art bottle blow molding machines that are efficient, cost-effective, and environmentally friendly.In addition to its focus on product innovation, {} is also known for its excellent customer service and support. The company has a team of highly skilled engineers and technicians who provide comprehensive technical assistance, installation, and maintenance services to ensure that its customers' machines operate at peak performance. This level of support has earned {} a strong reputation for reliability and customer satisfaction in the bottle blow molding machine industry.As a global player in the bottle blow molding machine market, {} has established a strong presence in various regions and countries around the world. The company's machines are widely used by manufacturers in the food and beverage, pharmaceutical, and personal care industries, among others. With a strong distribution network and partnerships with industry leaders, {} has been able to expand its reach and serve a diverse range of customers with varying production needs.Looking ahead, {} is poised to continue its growth and success in the bottle blow molding machine market. The company remains committed to delivering high-quality, innovative machines that meet the evolving demands of its customers and the industry as a whole. By staying at the forefront of technological advancements and maintaining its dedication to customer satisfaction, {} is well-positioned to remain a top choice for bottle blow molding solutions in the years to come.In conclusion, the bottle blow molding machine market is experiencing significant growth, driven by the increasing demand for plastic bottles across various industries. With its focus on innovation, quality, and customer support, {} has solidified its position as a leading player in the market. As the company continues to expand its global presence and enhance its product offerings, {} is poised for continued success and leadership in the bottle blow molding machine industry.